Furnace pipe mechanism with water pipe dust removing device

A technology of dust removal device and water pipe, which is applied in the field of boilers, can solve the problems of SAIC’s fast speed, small size, and high thermal efficiency, and achieve the effects of reducing heat loss, good dust removal effect, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

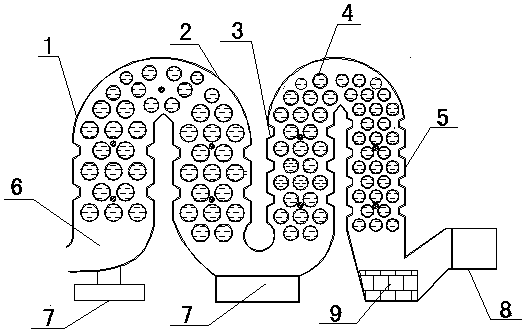

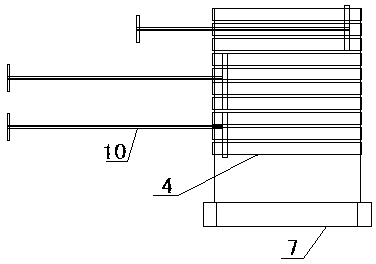

[0019] see figure 1 , figure 2 , image 3 , a furnace mechanism provided with a water pipe cleaning device, which is composed of a curved furnace and a pull plate device, a water pipe 4 is arranged inside the furnace furnace, and the pull plate device 10 is composed of a pull rod and a dust cleaning board, so The plate pulling device 10 described above maintains one degree of freedom of movement, and the direction of the degree of freedom of movement is consistent with the axial direction of the water pipe 4 . In actual working engineering, a part of soot and silicon dioxide residues will be deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com