Free-form surface morphology three-dimensional measurement method and device

A three-dimensional measurement and curved surface technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low zero-order spectrum energy utilization, frequency filling, etc., and achieve convenient image field correction, reduce wave aberration, and high contrast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment:

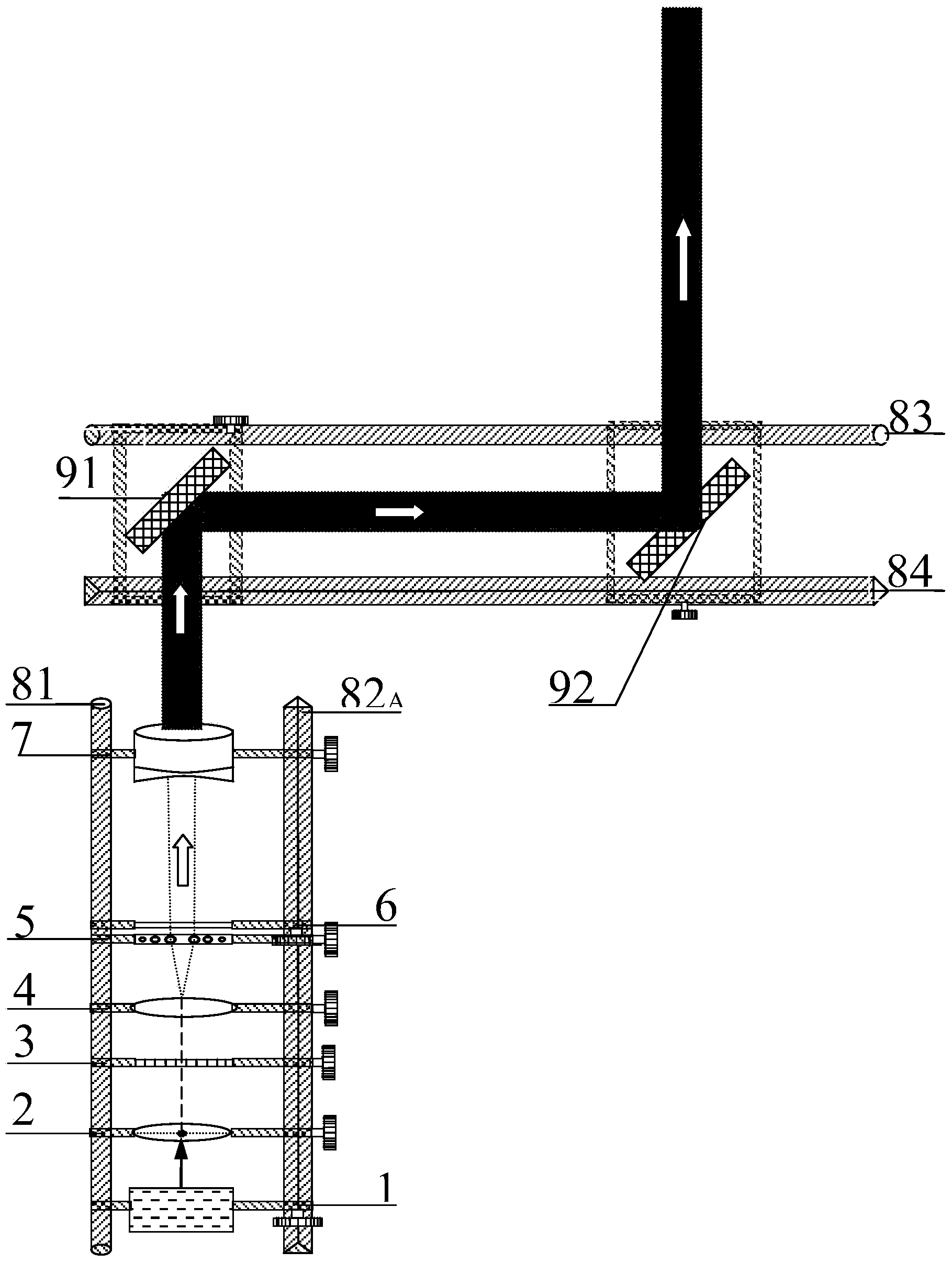

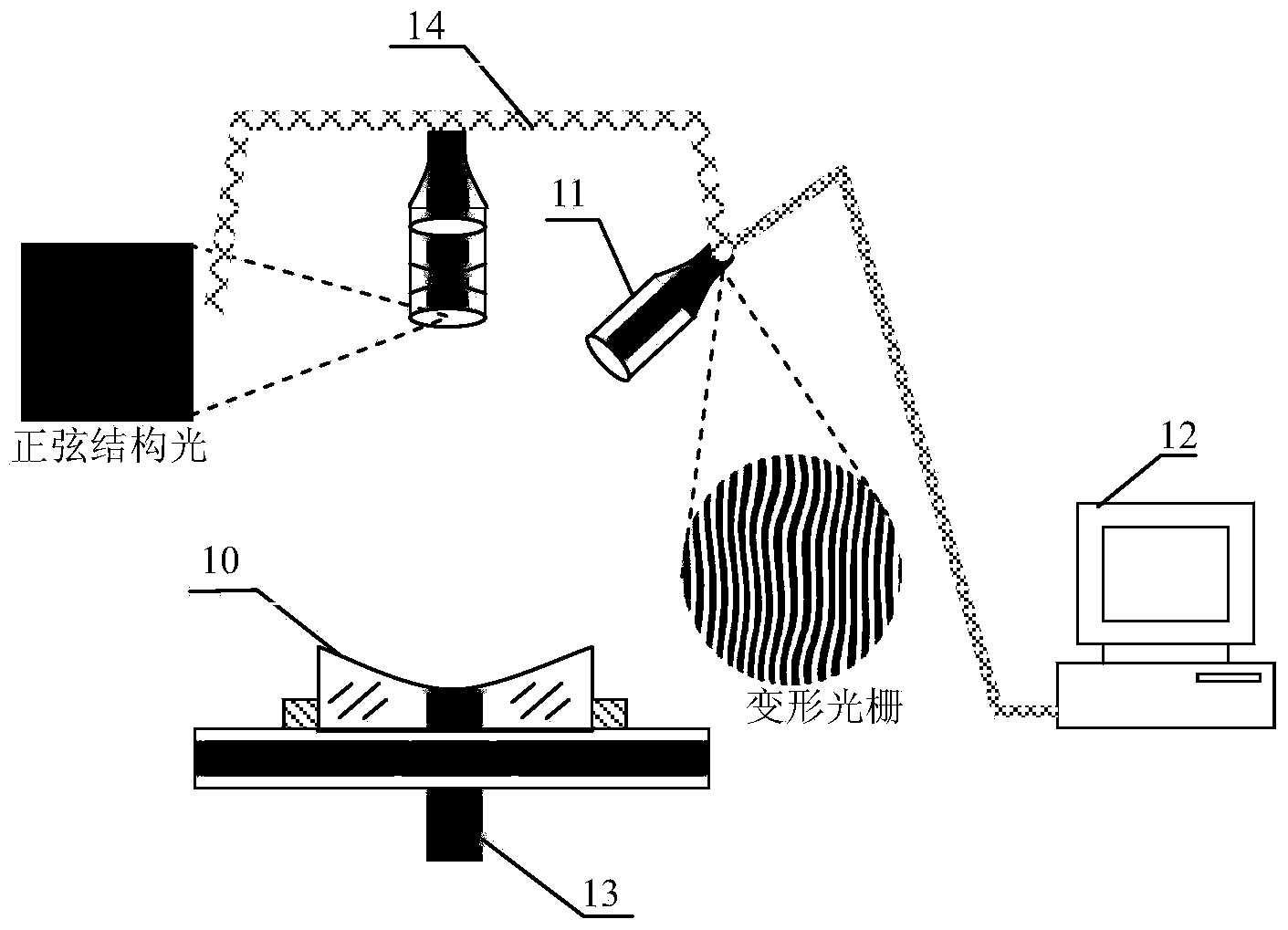

[0021] Please also see figure 1 and figure 2 The three-dimensional measurement device for free-form surface profile of the present invention includes a laser 1, a beam shaping system 2, a rectangular grating 3, a monochromatic Fourier transform lens 4, a spectrum selector 5, a wave plate 6, a monochromatic variable magnification lens 7, and a precision screw. 81. Precision guide rail 1 82, total reflection mirror 1 91, total reflection mirror 2 92, precision lead screw 2 83, precision guide rail 2 84, free-form surface to be tested 10, high-speed high-definition camera 11, computer and software processing system 12, machine tool platform Main shaft 13, gantry cantilever beam 14.

[0022] Among them, the beam shaping system is located behind the laser, which expands, collimates, and shapes the laser beam; the rectangular grating is located behind the beam shaping system, and positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com