Spacecraft ontrack leakage orientation method

A spacecraft and sensor array technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems that cannot meet engineering needs, unstable orientation results, complex noise, etc. , achieve high orientation accuracy and stability, improve orientation accuracy and stability, and overcome noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. These specific implementations are exemplary and are not intended to limit the protection scope of the present invention.

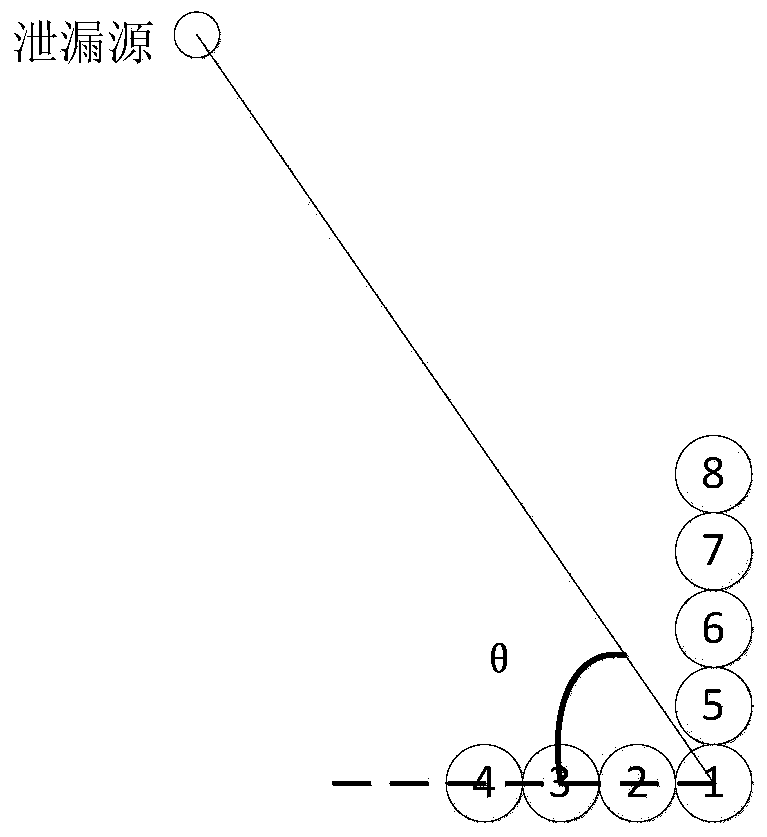

[0032] In the context of the present invention, 8 acoustic emission sensors are arranged in an L-shaped 8-element sensor array.

[0033] figure 1 It is a schematic diagram of leak orientation using an 8-element L-shaped acoustic emission sensor array in the present invention. The present invention uses 8 array element L type acoustic emission sensor arrays, 8 40dB preamplifiers (purchased from PAC company) and 8 channel signal acquisition analyzers, 8 array element sensor arrays are fixed on the inner surface of the spacecraft cabin by coupling agent, The sensor array is in electrical communication with the preamplifier and the signal acquisition analyzer. The method uses an 8-element L-shaped acoustic emission sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com