Rotating platform condensation heat transfer experimental device and rotating platform condensation heat transfer experimental method

A technology of condensing heat exchange and rotating platform, which is applied in the field of two-phase flow experimental measurement, can solve the problems that the turntable can only rotate horizontally, but cannot rotate vertically, and the operation mode of the drying cylinder is inconsistent, so as to reduce the effect of centrifugal force, run stably, and reduce the temperature difference. constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

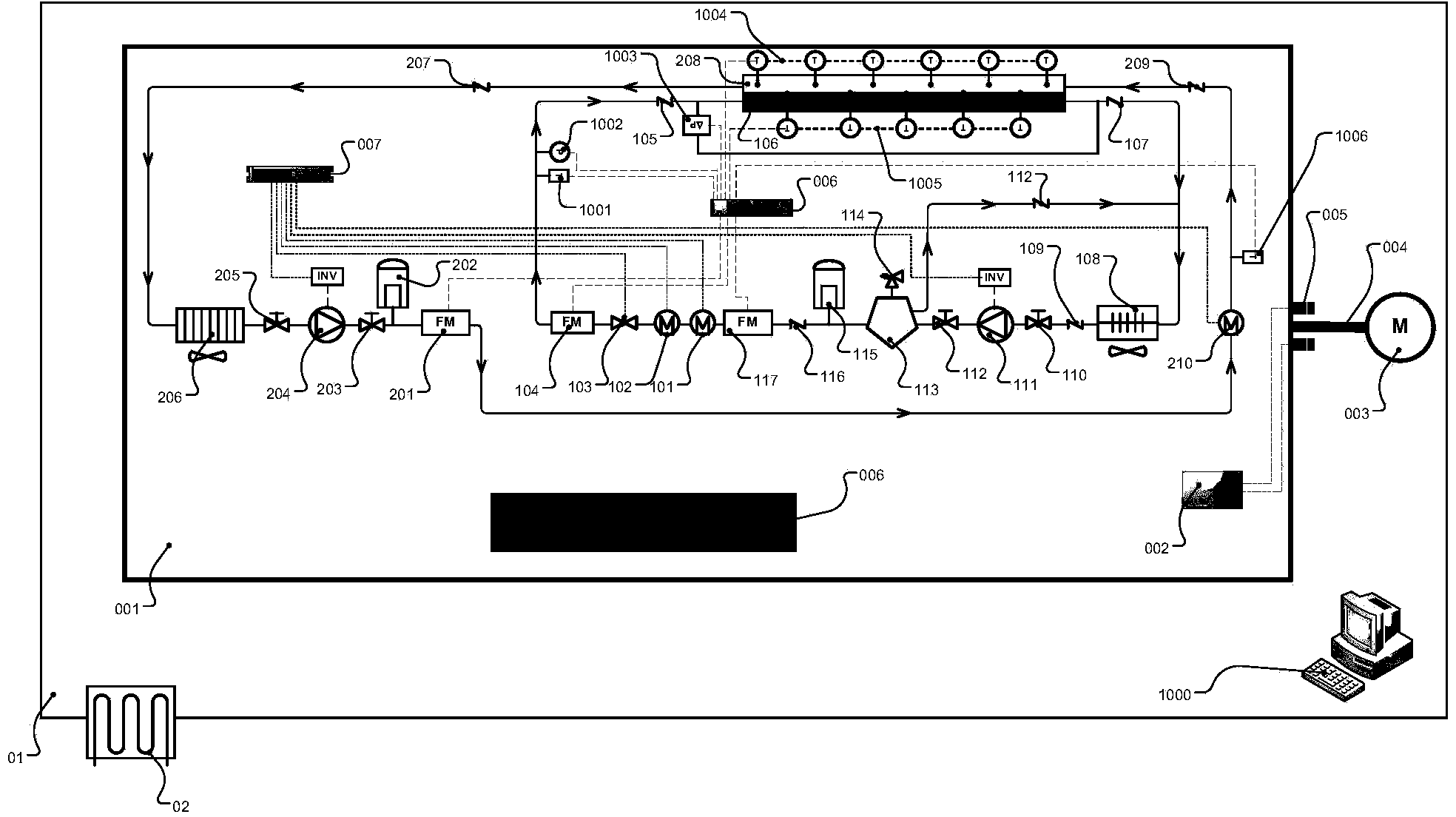

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] see figure 1 , the rotating platform condensation heat transfer experimental device of the present invention consists of a rotating platform, a medium circuit, a coolant circuit and a measurement system. The rotating platform is composed of a turntable 001, a speed-regulating motor 003, a main shaft 004, and a counterweight 006; the medium circuit consists of a generator 101, a superheater 102, a medium test tube 106, an aftercooler 108, a medium pump 111, and a gas-liquid separator 113 Composition; the coolant loop is made up of coolant test tube 208, cooler 206, coolant pump 204 and reheater 210;

[0034] figure 1 In the rotating platform condensation heat exchange experimental device shown, the outlet of the medium test tube 106 and the inlet of the medium test tube 106 are sequentially connected with a check valve 107, an aftercooler 108, a check valve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com