A high bonding strength magnesium-aluminum composite thin plate belt differential temperature asynchronous rolling composite method

A composite sheet, bonding strength technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of high composite temperature of single-layer sheet, warping of sheet, cracking of composite sheet/coil, etc., to improve stress- Strain proximity, the effect of reducing the peak value of residual stress, and improving the interface bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

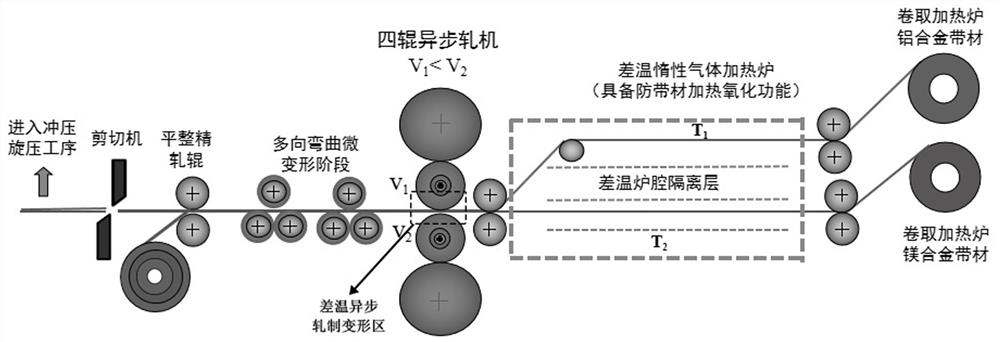

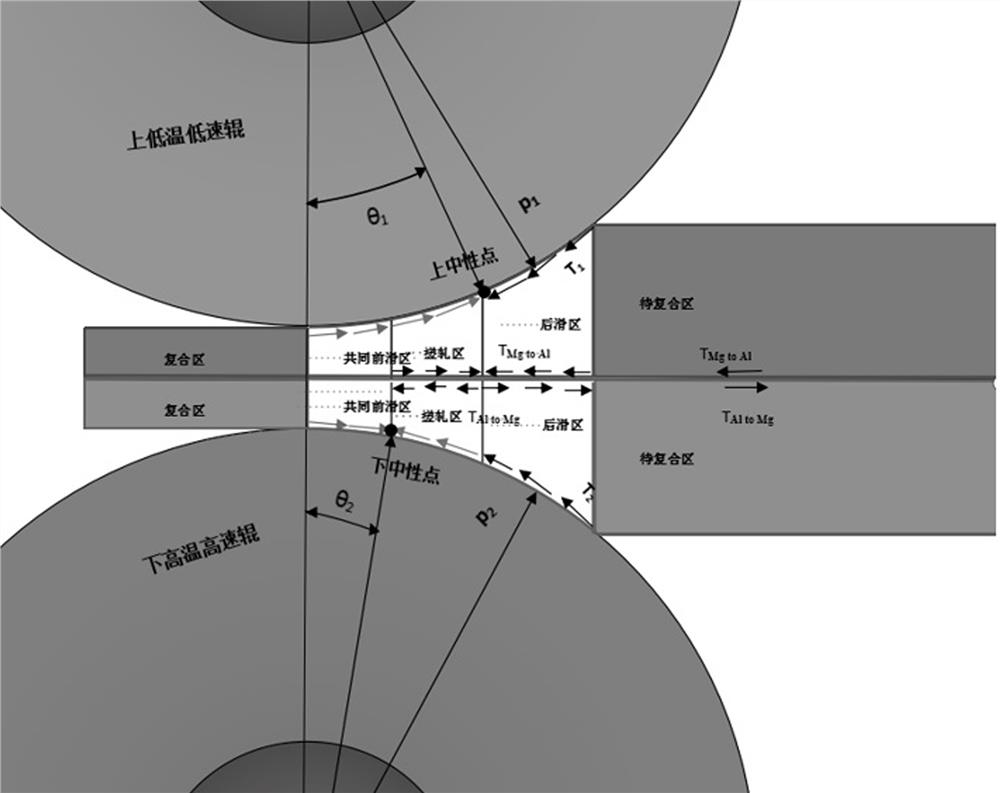

[0029] The blanks selected in this embodiment are: AZ31B rolled magnesium coil with a thickness of 8.5 mm, and AA6010 aluminum coil with a thickness of 6 mm. First of all, the abrasive belt with a grain size of 120 is selected, and the magnesium and aluminum alloy strips before compounding are subjected to grinding pretreatment at a speed of 12.5m / s. After high-pressure water cleaning, the cold air blower is blown dry, and the coil is curled online. . Place the ground AZ31B magnesium coil in the coiling heating furnace, heat it to 340°C, and keep it warm for 2 hours. Keep warm for 2h. Then the upper and lower coilers uncoil at the speed of 0.2m / s at the same time. After that, the magnesium and aluminum strips are heated online in the differential temperature inert heating furnace, and the temperature of the furnace wire in the aluminum strip heating furnace is 380 ℃, the furnace wire temperature in the heating furnace of the magnesium strip is 400 ℃, and the magnesium and al...

Embodiment 2

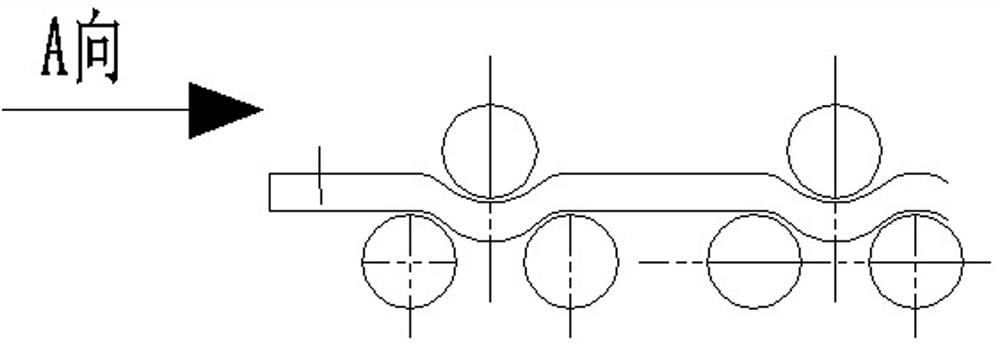

[0031] Such as figure 1 As shown, the blanks selected in this embodiment are: AZ31 as-rolled magnesium coil with a thickness of 4 mm, and AA5052 aluminum coil with a thickness of 3 mm. The magnesium and aluminum alloy strips before compounding are subjected to grinding pretreatment at a linear speed of 12.5m / s. The abrasive belts have a particle size of 100. After cleaning, air-cooled blow-drying methods are used to curl them into rolls online. The ground AZ31 thin coil is placed in a coiling heating furnace, heated to 320 ° C, and kept for 1 h. At the same time, the processed AA5052 aluminum coil, with a thickness of 3 mm, is placed in a coiling heating furnace, heated to 280 ° C, and kept for 1 h. Then the upper and lower coilers uncoil at the speed of 0.3m / S at the same time. After that, the magnesium and aluminum strips are heated online in the differential temperature inert heating furnace, and the temperature of the furnace wire in the heating furnace of the aluminum str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com