A method for preparing a transmissive laser micro-propelled thin-film target strip and its manufacturing equipment

A micro-propulsion and transmissive technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems such as difficult to make target tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1 equipment

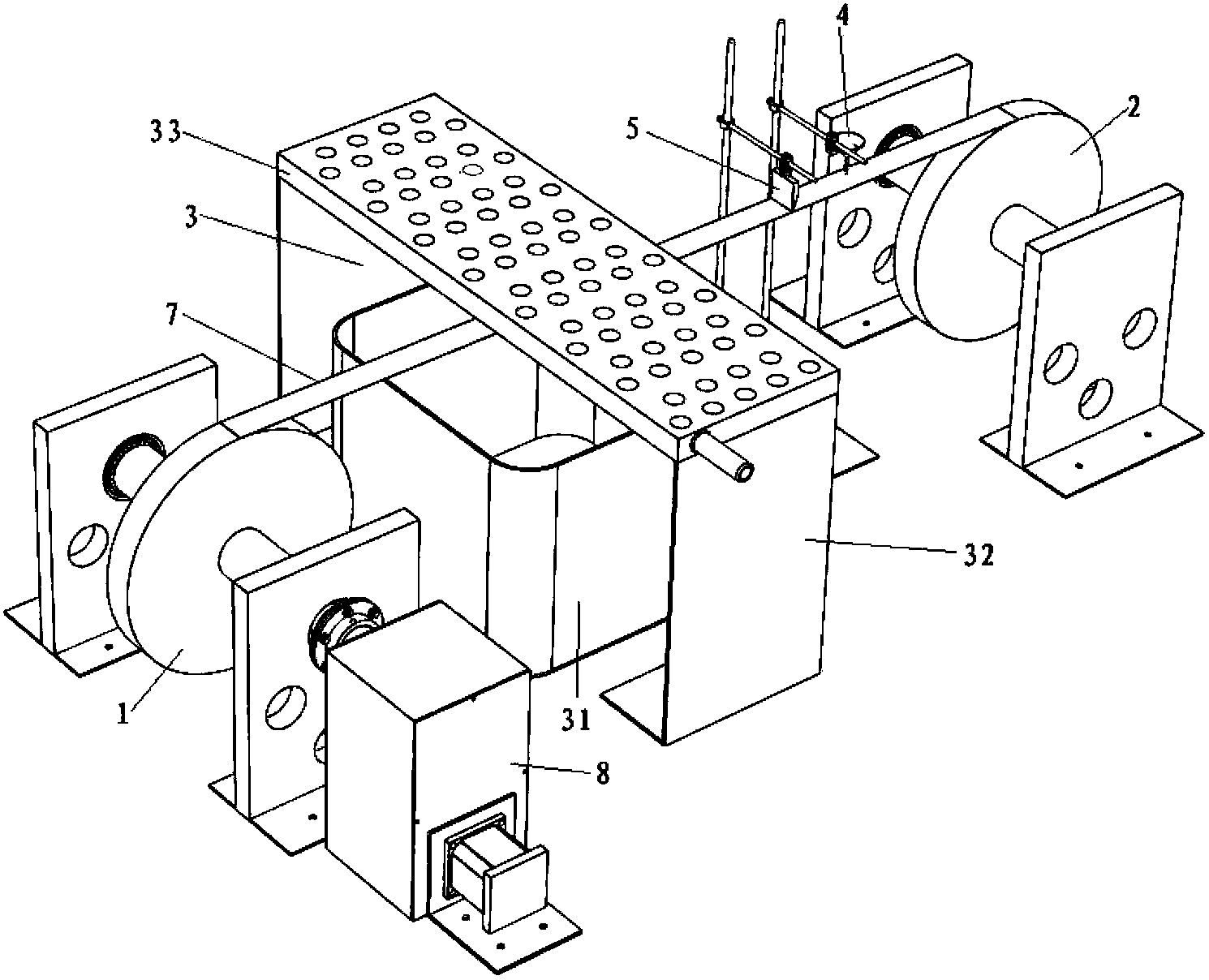

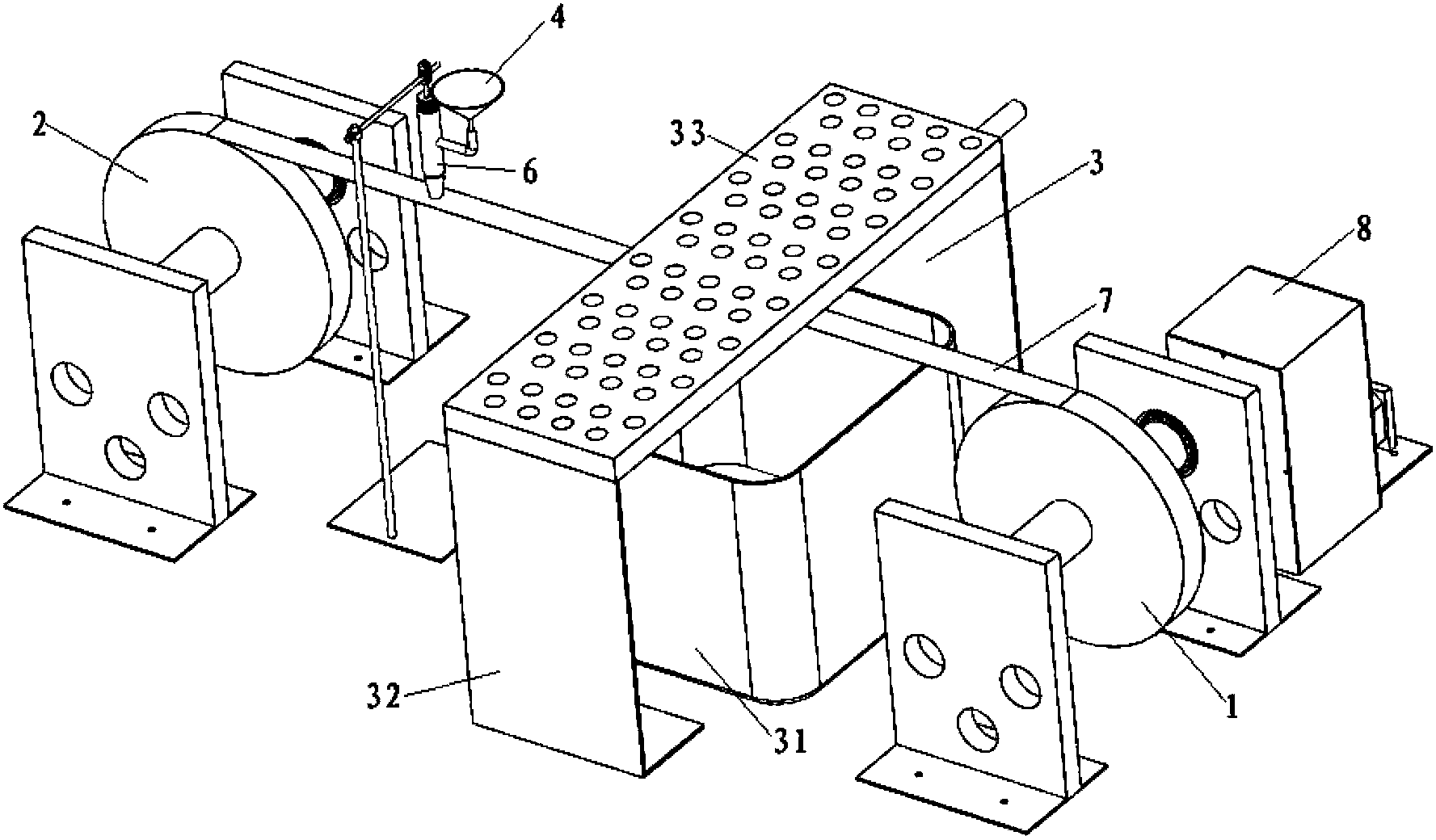

[0066] like figure 2 , 3 Shown, a kind of equipment for making target material for laser micro-propelling, it comprises:

[0067] Driving wheel 1, driven wheel 2, one end of the base film 7 is wound on the driven wheel 2, and the other end is connected on the driving wheel 1, and the driving wheel 1 drives the driven wheel 2 to rotate;

[0068] The heating system 3 is arranged between the driving wheel 1 and the driven wheel 2, and heats the base film 7;

[0069] The feeding device 4 is arranged between the heating system 3 and the driven wheel 2 to add ablation layer material to the base film 7 .

[0070] The driving wheel 1 and the driven wheel 2 are respectively placed on a support provided with a rotating shaft, and the support is a fixed support. The feeding device 4 selected by the present invention is a funnel, and the feeding device is also provided with a screw switch.

[0071] Wherein, the heating system 3 includes a heating barr...

Embodiment 2

[0088] The preparation of embodiment 2 target bands

[0089] Prepare ablative material in the following proportions:

[0090] 80 energy supply materials,

[0091] 20 parts of additives.

[0092] (1) Prepare energy supply materials and additives according to the above proportions, and dissolve them in solvents respectively to obtain energy supply material solutions and additive solutions;

[0093] Among them, the energy supply material: 4 grams of single-base drug (97% nitrocellulose content) dissolved in a mixture of 55 milliliters of acetone and 3.6 milliliters of water, and stirred evenly with a stirrer after standing for 24 hours.

[0094] Additive: 1 gram of nanocarbon dissolved in 5ml of acetone.

[0095](2) Mix the mixed solution obtained in step (1), and after stirring for 15 minutes, add acetone to make the mixed solution reach a viscosity of 17s (tested with 4 cups), and stir evenly to obtain a transmission target ablation material mixed solution

[0096] Use the ...

Embodiment 3

[0103] The preparation of embodiment 3 target bands

[0104] Prepare ablative material in the following proportions:

[0105] 60 energy supply materials,

[0106] Improve bonding material 35 parts,

[0107] Additives 5 parts.

[0108] (1) Prepare the energy-supplying material, cohesion-improving material and additives according to the above proportions, and dissolve them in a solvent respectively to obtain the energy-supplying material solution, the cohesion-improving material solution and the additive solution;

[0109] Among them, the energy-supplying material: 8 grams of the single-base drug was dissolved in 120 milliliters of ethyl acetate, and stirred evenly with a stirrer after standing for 24 hours.

[0110] Adhesion-improving material: 4.6 g of HTPB was dissolved in 10 ml of ethyl acetate.

[0111] Additives: 0.7 g nanocarbon dissolved in 5 ml ethyl acetate, 0.2 ml hexamethylene diisocyanate (HDI) dissolved in 2 ml ethyl acetate and one drop (0.02 ml) of dibutyltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com