High-voltage wiring harness conductivity automatic-testing device of electric vehicle

A technology of automatic testing device and high-voltage wiring harness, which is applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of lack of versatility, long manual operation time, manual wiring, etc., and solve the difficulty of continuity test, Effect of increasing test speed and reducing design size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

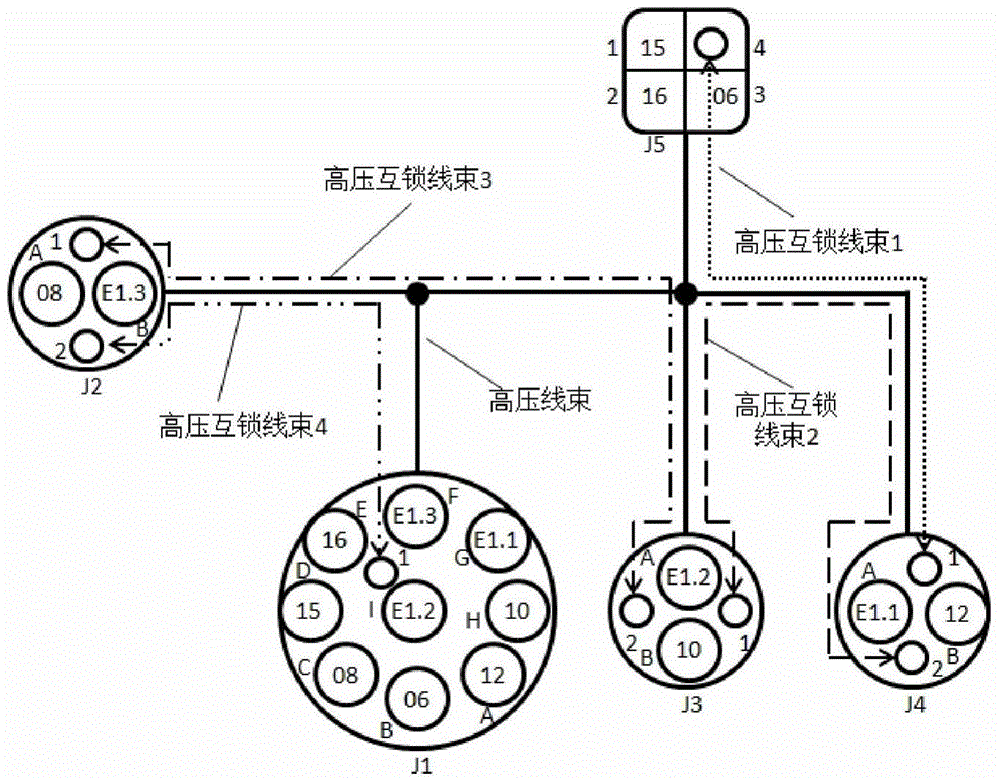

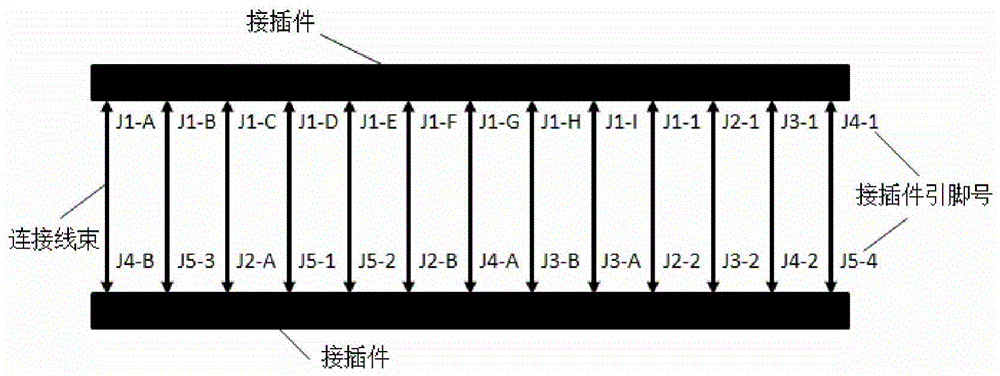

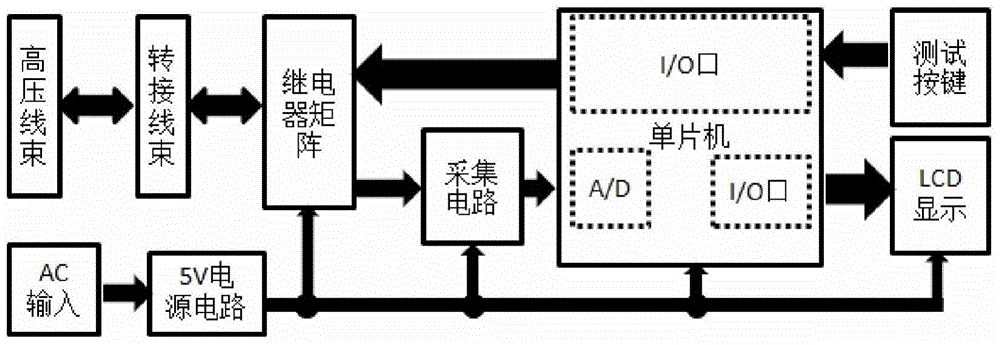

[0034] On the basis of fully analyzing the high-voltage connectors connected by the high-voltage wire harness, the present invention designs the transfer wire harness and the relay matrix, controls the relay matrix through the I / O port of the single-chip microcomputer, applies +5V DC voltage to the detection point during the test, and uses the internal A / O of the single-chip microcomputer to control the relay matrix. D reads the voltage value output by the acquisition circuit, and judges the continuity of each terminal of the high-voltage harness high-voltage connector according to the A / D acquisition value, and sends it to the LCD for display. The invention makes full use of the LCD display, and testers can complete the continuity test of the high-voltage wire harness according to the operation instructions, without having to understand and grasp the internal pin definitions of each high-voltage connector of the high-voltage wire harness.

[0035] The schematic diagram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com