Forced-oil-circulation, energy-saving and low-noise air-cooled transformer cooling system

A technology for forced oil circulation and cooling system, applied in the field of air-cooled transformer cooling system, can solve the problems of increased leakage points, unsatisfactory energy saving, environmental protection, large transformation workload, etc. Effects of noise reduction and maintenance, improved heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

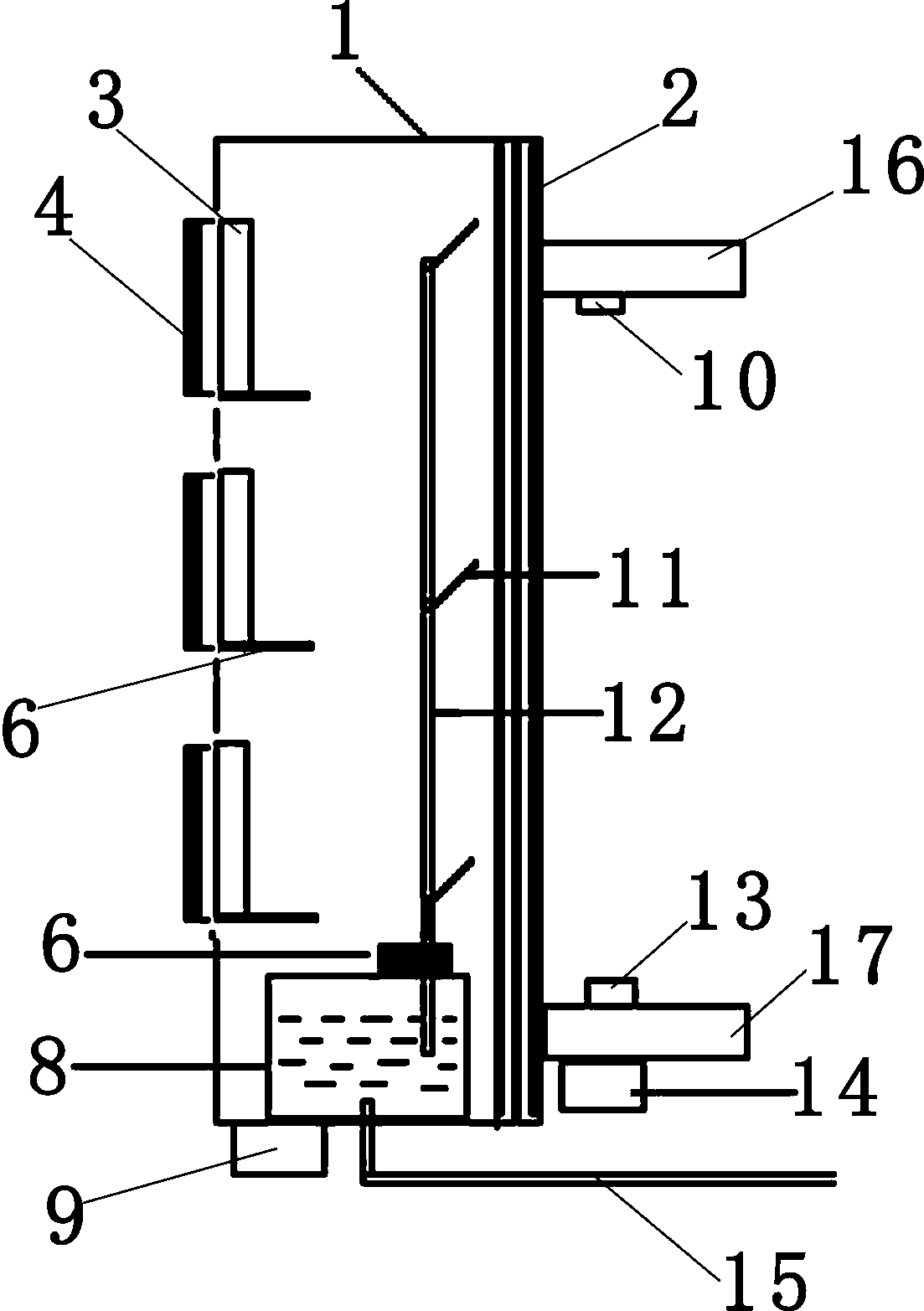

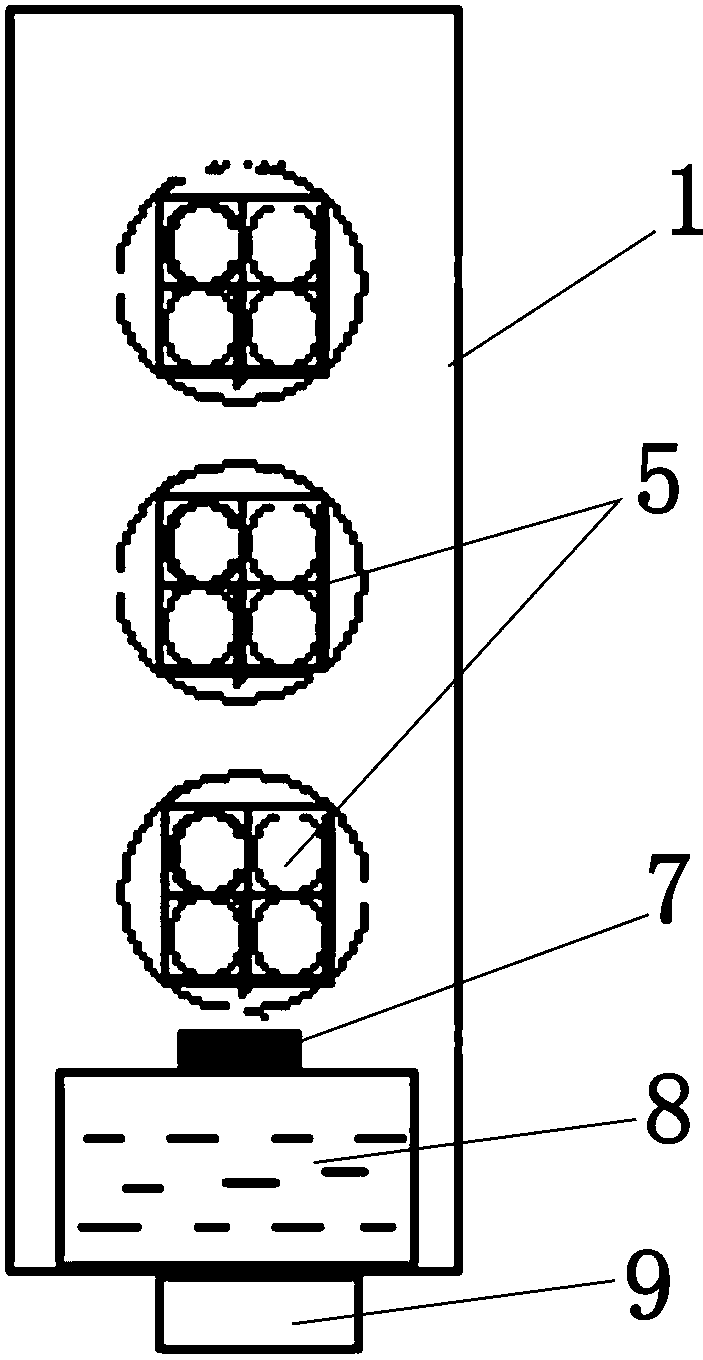

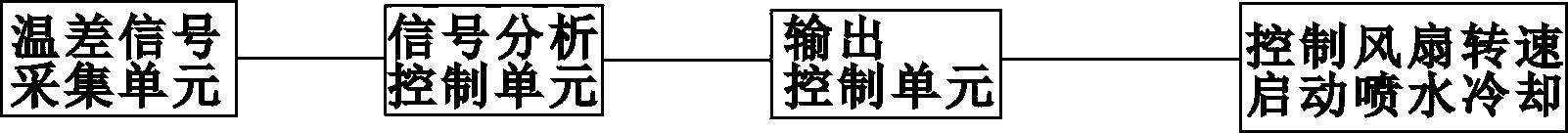

[0030] Such as figure 1 , figure 2 As shown, a forced oil circulation energy-saving and low-noise air-cooled transformer cooling system includes a cooling frame 1, a heat dissipation pipe 2 fixedly connected to the cooling frame 1, and an air guide tube 3, which are installed at the air inlet of the air guide tube 3 There is a dust-proof and sound-absorbing net 4, and a fan motor 5 and a water spray cooling device are installed in the cooling frame 1. A control circuit module is arranged in the sub-control box 9, and the control circuit module is respectively connected with the first temperature sensor 10 installed on the oil outlet pipe 16 and the second temperature sensor 13 installed on the oil inlet pipe 17, and the control circuit module is connected with the fan motor 5 and the spray nozzle. Water cooling unit. The water spray cooling device includes a water tank 8 connected to a water supply pipe 15, the water tank 8 connected to a water pipe 12 through a water pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com