Huichun capsule and preparation method thereof

A technology for forgetfulness, kidney deficiency and low back pain, which can be used in capsule delivery, pharmaceutical formulations, medical preparations with inactive ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 18g Gastrodia elata, 45g ferulae, 1.8g gecko, 25.2g curculigo, 63g bullwhip, 31.5g actinolite, 2.5g cistanche, 27g schisandra, 1.3g antler gum, 36g epimedium, 50.4 g of Acanthopanax extract g, Phellodendron 12.6g, crushed into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 30Mpa, extraction temperature 30°C, separator pressure 10Mpa, separator temperature 50°C, separation time 2 hours, carbon dioxide flow rate per hour 40L to obtain the extract; take the extract and dry it under reduced pressure at 60°C to obtain a dry paste; add 150g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 45g, cross-linked polyvinylpyrrolidone 45g, cross-linked carmellose sodium 35g, mix well, wet granulate with 50% ethanol, dry at 60℃, add sodium carboxymethyl starch 7g, stearic ...

specific Embodiment 2

[0033] Take 18g Gastrodia elata, 45g ferulae, 1.8g gecko, 25.2g curculigo, 63g bullwhip, 31.5g actinolite, 2.5g cistanche, 27g schisandra, 1.3g antler gum, 36g epimedium, 50.4 g of Acanthopanax extract g, Phellodendron 12.6g, crushed into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 40Mpa, extraction temperature 40°C, separator pressure 20Mpa, separator temperature 60°C, separation time 4 hours, carbon dioxide flow rate per hour 50L to obtain the extract; take the extract and dry it under reduced pressure at 80°C to obtain a dry paste; add 200g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 55g, cross-linked polyvinylpyrrolidone 55g, cross-linked sodium carboxymethylcellulose 45g, mix well, wet granulate with 70% ethanol, dry at 80℃, add sodium carboxymethyl starch ...

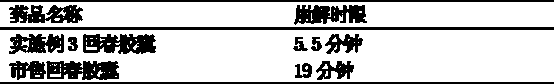

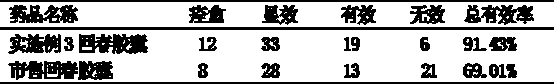

Embodiment 3

[0035] Take 18g Gastrodia elata, 45g ferulae, 1.8g gecko, 25.2g curculigo, 63g bullwhip, 31.5g actinolite, 2.5g cistanche, 27g schisandra, 1.3g antler gum, 36g epimedium, 50.4 g of Acanthopanax extract g, Phellodendron 12.6g, crushed into 60 mesh coarse powder, extracted by carbon dioxide supercritical extraction, extraction pressure 35Mpa, extraction temperature 35°C, separator pressure 15Mpa, separator temperature 55°C, separation time 3 hours, carbon dioxide flow rate per hour 45L to obtain the extract; take the extract and dry it under reduced pressure at 70°C to obtain a dry paste; add 175g of mannitol to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 50g, cross-linked polyvinylpyrrolidone 50g, cross-linked sodium carboxymethylcellulose 40g, mix well, wet granulate with 60% ethanol, dry at 70℃, add sodium carboxymethyl starch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com