Depth-induced crushing mineral separation technology of super-lean magnetic iron ore

A magnetite ore and process technology, which is applied in the field of deep crushing and beneficiation of ultra-lean magnetite ore, can solve the problems of high tailings processing cost, low economic benefit of beneficiation, large raw ore grinding capacity, etc., and achieve reduction of ore grinding capacity, The effect of saving mineral processing costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

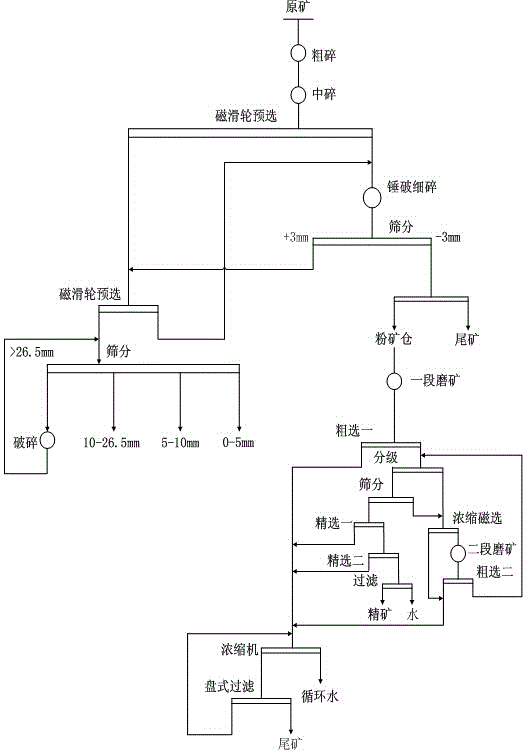

Image

Examples

Embodiment 1

[0021] 1. The above ore is crushed by PXZ-1417 gyratory crusher and PYT-B2235 cone crusher, and then pre-selected by two-stage CT-1014 magnetic roller. The pre-selected concentrate is fed into 8 PC-M1825 hammer crushers for fine crushing.

[0022] 2. The finely crushed products are screened, and the tailings >3mm and the first-stage magnetic pulley pre-selection enter the second-stage magnetic pulley dry separation, and the concentrate returns to the fine crushing operation. The tailings enter the screening, and the particle size is divided into four grades of 0-5mm, 5-10mm, 10-26.5mm, and >26.5mm, which can be used as sand and gravel aggregate products. The ore <3mm enters the CTG-1030 dry separation machine for dry separation, throwing away about 70% of the tailings to effectively reduce the amount of grinding;

[0023] 3. The dry-separated concentrate is fed into the MQG3660 ball mill, the ground product enters the primary roughing magnetic separator, the tailings enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com