Full-automatic chain saw sharpener and chain grinding method thereof

A chain grinding machine, fully automatic technology, applied in the field of grinding tools, can solve problems such as jamming, affecting grinding accuracy, poor dustproof effect, etc., and achieve the effect of preventing jamming and not being easy to jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

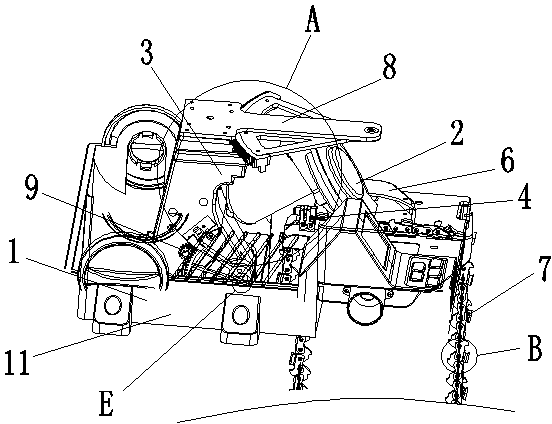

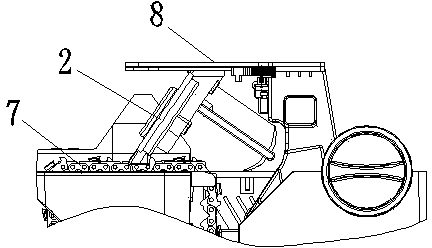

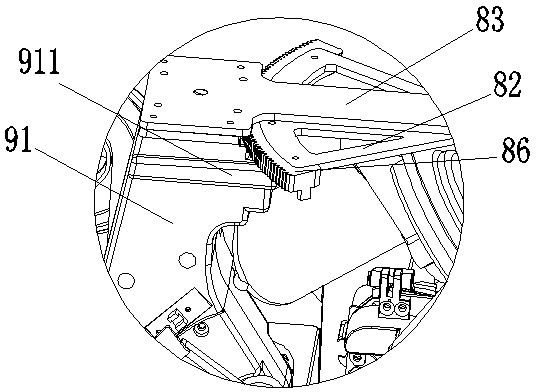

[0065] see Figure 1 to Figure 38 , The fully automatic chain grinding machine in this embodiment includes a housing 1, a grinding device 2, an action device 3, a feeding device 4, a locking device 5, a dust suction device 6 and a saw chain 7. The saw chain 7 includes a cutting chain 71 and a center guide tooth 72 . The cutting chain piece 71 includes a cutting piece 711 and a limiting tooth 712 .

[0066] The grinding device 2 , the action device 3 and the feeding device 4 in this embodiment are all supported in the casing 1 .

[0067] The feeding device 4 in this embodiment includes a hanging chain platform 41 , a pushing device 42 , a driving device 43 , a feeding photoelectric 44 , and a photoresistive strip 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com