A vacuum insulation panel heating and sealing system

A vacuum insulation panel and sealing technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of low temperature control accuracy, low automation level, frequent replacement, etc., and achieve easy automation and low power consumption , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical solution of the above-mentioned invention in more detail, specific embodiments are listed below, and the technical effects are demonstrated in conjunction with the accompanying drawings; it should be emphasized that these embodiments are used to illustrate the present invention and not limit the scope of the present invention.

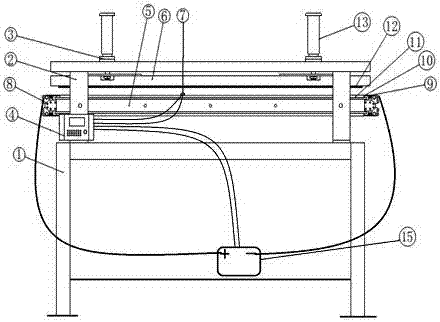

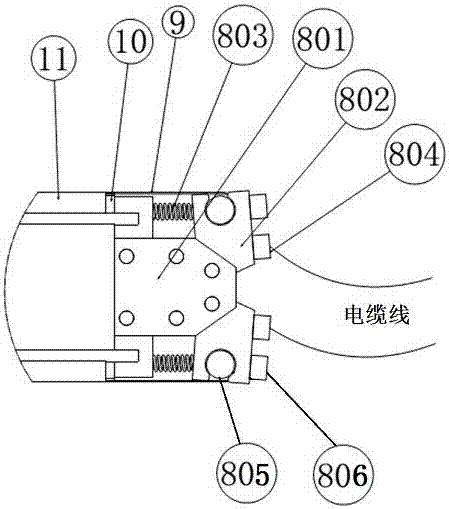

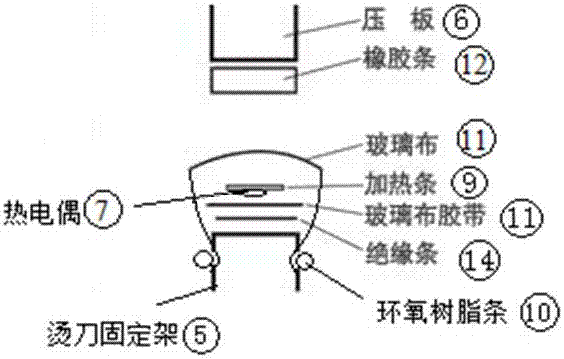

[0021] Such as figure 1 , figure 2 and image 3 The vacuum insulation panel heating and sealing system shown includes a base 1, a bracket 2, an ironing knife fixing frame 5, an ironing knife pressing plate 6, a thermocouple 7, and a sealing ironing knife 9. The support 2 is fixed on the base 1, and the The ironing knife fixed frame 5 is fixed on the support 2, and the sealing ironing knife 9 and the thermocouple 7 are set on the described ironing knife fixed frame 5, and are wrapped with anti-sticking glass cloth 11, separated from the ironing knife fixed frame 5 by the insulating strip 14 Open, the bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com