Method for preparing low-temperature cured polyester resin

A polyester resin, low-temperature technology, applied in the field of preparation of low-temperature curing polyester resin, can solve the problems of insufficient leveling, high reactivity, insufficient reactivity, etc., achieve good leveling and chemical resistance, and good storage stability , Improve the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

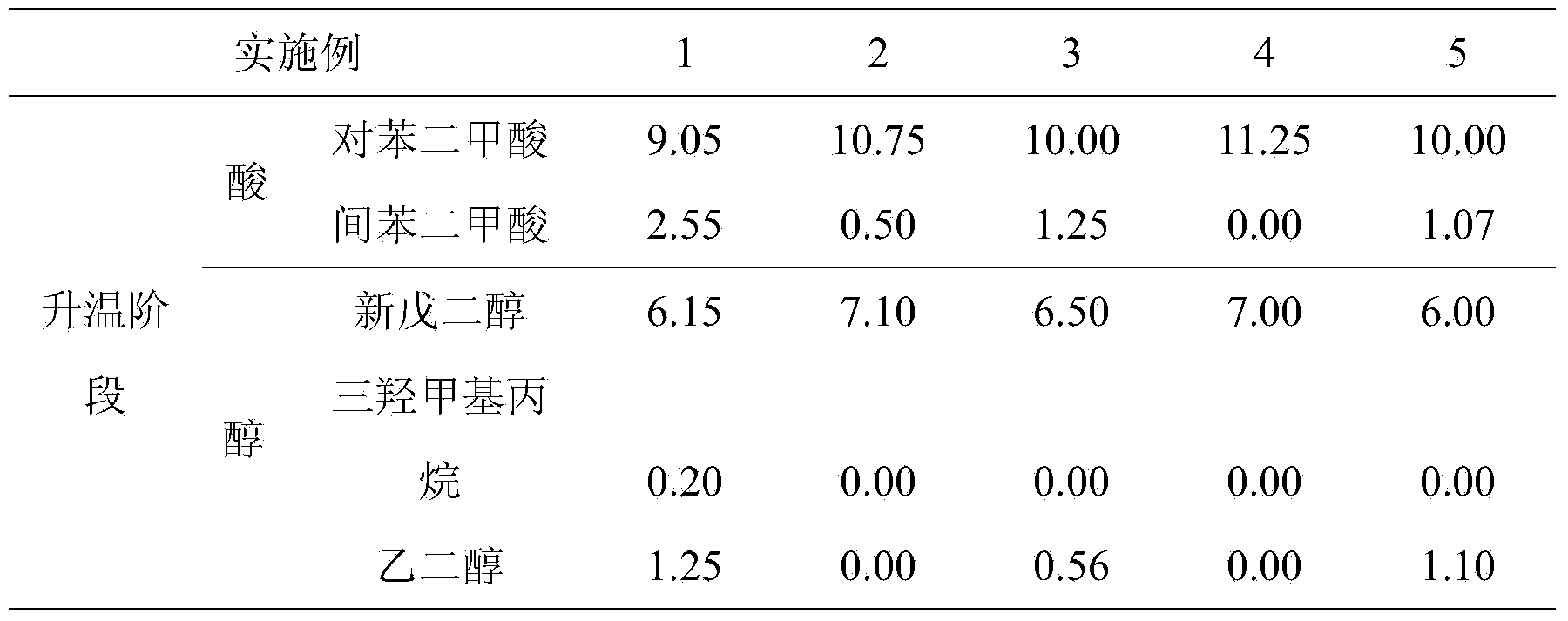

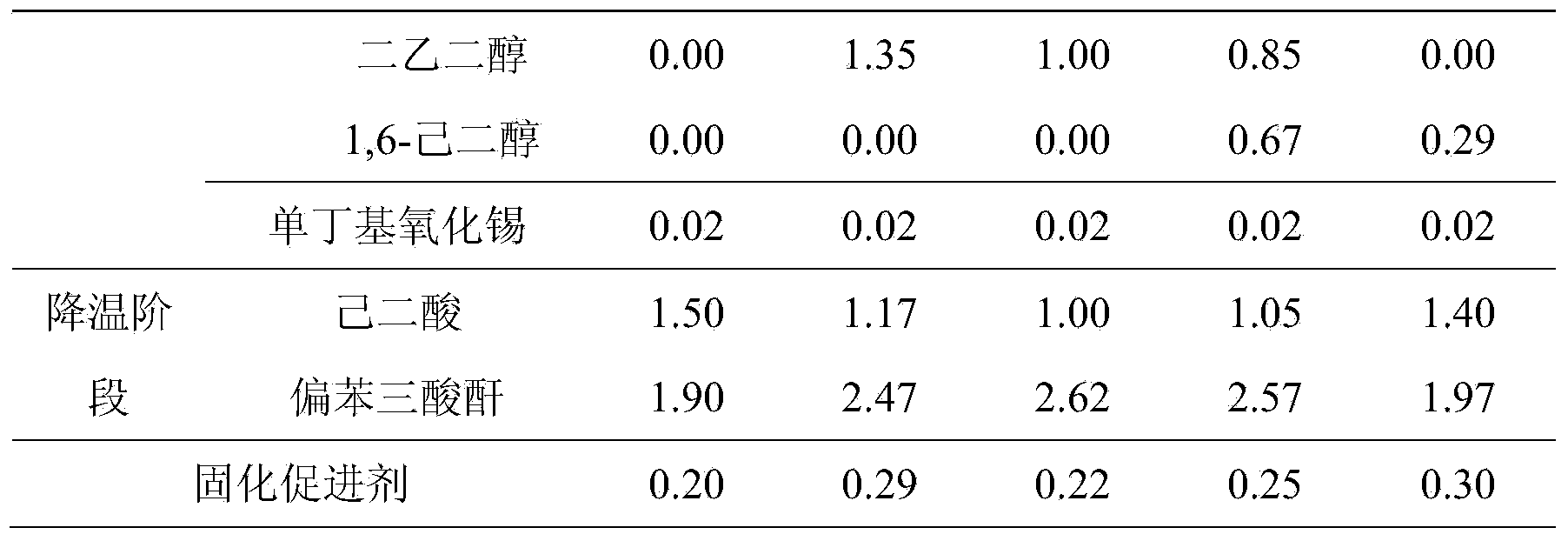

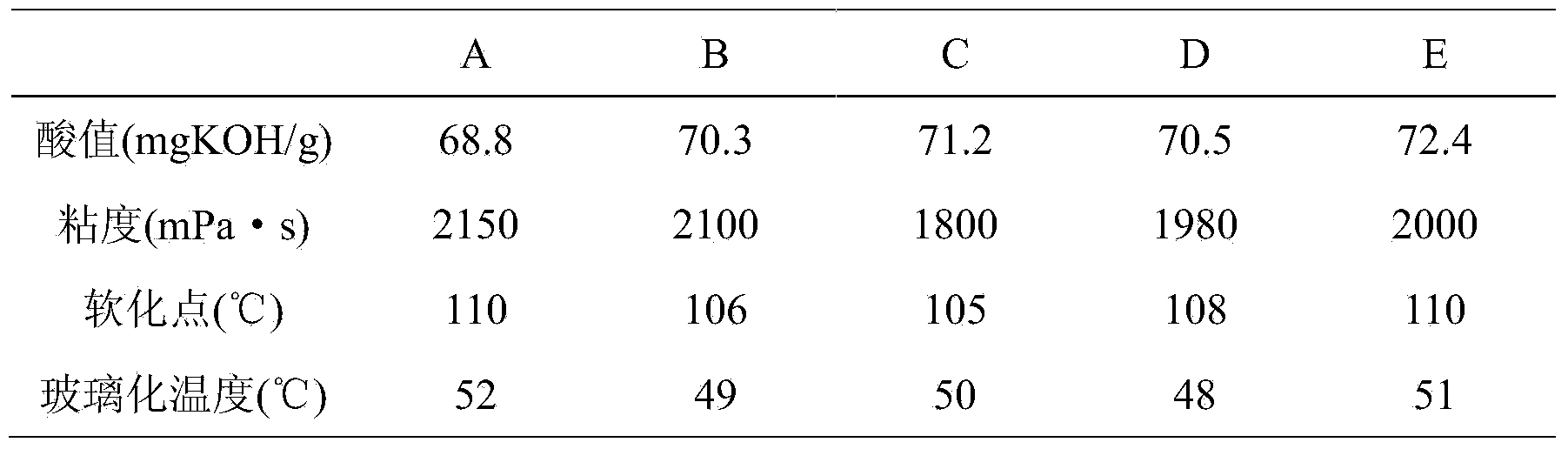

Embodiment 1

[0021] A preparation method of polyester resin, the steps are as follows:

[0022] (1) Heating stage: raise the temperature of the reaction kettle to 110°C, start stirring, and put in the formulated amount of alcohol, acid, and formulated amount of esterification catalyst in sequence. Raise the temperature to 215°C at a heating rate of 2°C / 15min, and finally raise the temperature to 247°C at a heating rate of 2°C / 15min, maintain the reaction until the top temperature of the reactor drops below 70°C, and take a sample to detect an acid value of 9.3mgKOH / g;

[0023] (2) Cooling stage: lower the temperature of the kettle to 185°C, put in acid, and then raise the temperature to 220°C for maintenance. After the top temperature of the reaction kettle drops below 60°C, take a sample to detect an acid value of 83.4mgKOH / g;

[0024] (3) Vacuum stage: At 210°C, vacuumize for 3 hours at a vacuum degree of -0.094MPa, take a sample to detect an acid value of 71.5mgKOH / g and a viscosity of ...

Embodiment 2

[0028] A preparation method of polyester resin, the steps are as follows:

[0029] (1) Heating stage: raise the temperature of the reaction kettle to 98°C, start stirring, and put in the formulated amount of alcohol, acid, and formulated amount of esterification catalyst in sequence, seal the kettle and raise the temperature to 179°C, Raise the temperature to 210°C at a heating rate of 1°C / 15min, and finally raise the temperature to 248°C at a heating rate of 1°C / 15min, maintain the reaction until the top temperature of the reactor drops below 70°C, and take a sample to detect an acid value of 7.9mgKOH / g;

[0030] (2) Cooling stage: lower the temperature of the kettle to 190°C, put in acid, and then raise the temperature to 230°C for maintenance. After the top temperature of the reaction kettle drops below 60°C, take a sample to detect an acid value of 82.6mgKOH / g;

[0031] (3) Vacuum stage: Under the condition of 220°C, vacuumize at a vacuum degree of -0.098MPa for 2.5h, take...

Embodiment 3

[0035] A preparation method of polyester resin, the steps are as follows:

[0036] (1) Heating stage: raise the temperature of the reaction kettle to 105°C, start stirring, and put in the formulated amount of alcohol, acid and the formulated amount of esterification catalyst in sequence. Raise the temperature to 220°C at a heating rate of 3°C / 15min, and finally raise the temperature to 246°C at a heating rate of 3°C / 15min, maintain the reaction until the top temperature of the reactor drops below 70°C, and take a sample to detect the acid value of 7.5mgKOH / g;

[0037] (2) Cooling stage: lower the temperature of the kettle to 180°C, put in acid, and then raise the temperature to 225°C for maintenance. After the top temperature of the reaction kettle drops below 60°C, take a sample to detect the acid value of 83.1mgKOH / g;

[0038] (3) Vacuum stage: Under the condition of 205°C, vacuumize for 3.5h at a vacuum degree of -0.094~-0.098MPa, take a sample to detect an acid value of 71...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com