Process and structure for adhering electronic paper and touch screen

An electronic paper and touch screen technology, applied in the direction of adhesive heating, bonding method, electrical digital data processing, etc., can solve problems such as failure to meet electronic paper lamination process requirements, affecting product quality, and overflowing glue. , to achieve mass production, no yellowing, good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

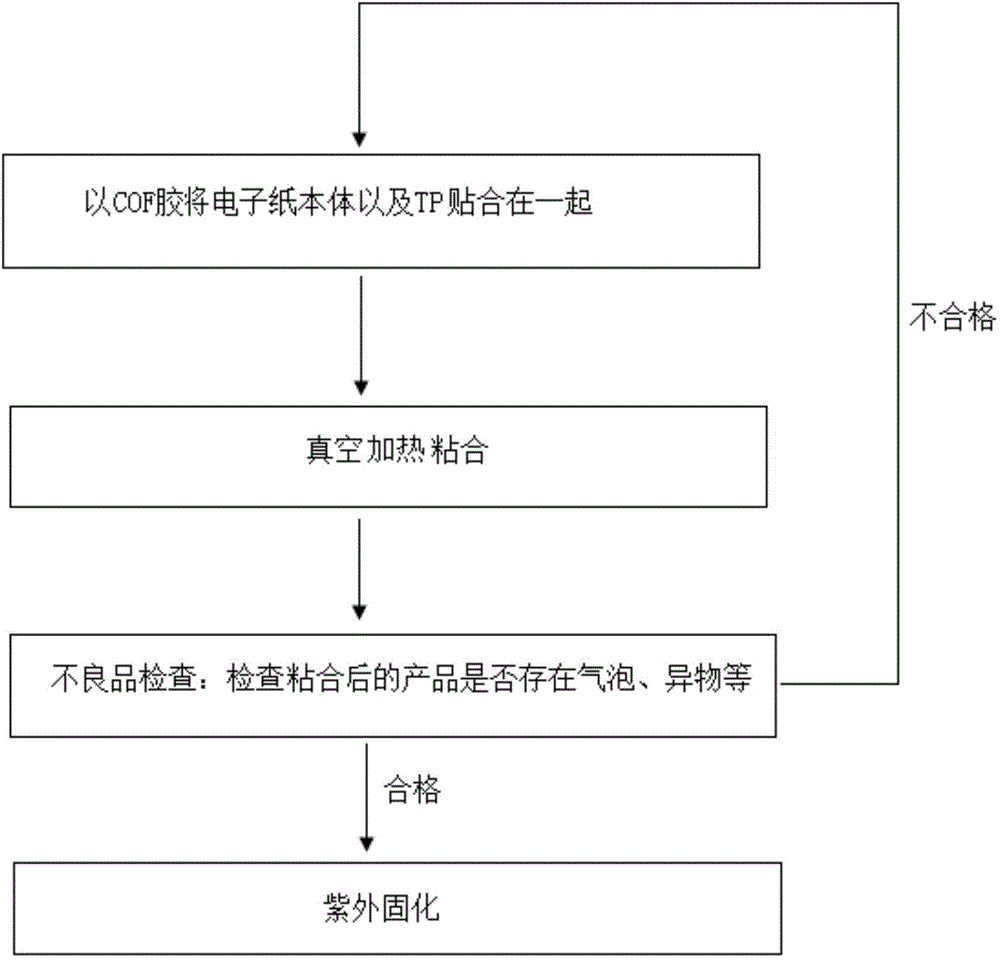

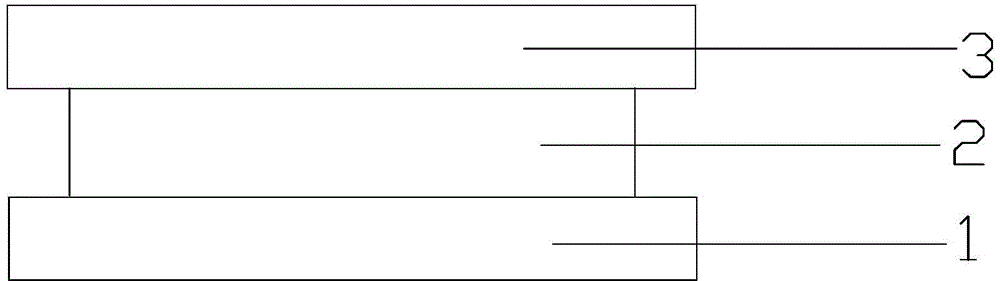

[0030] A bonding process of electronic paper and touch screen, comprising the following steps:

[0031] 1) Bonding: Glue the COF glue on the surface of the electronic paper body to form an adhesive layer with a thickness of about 175 μm, glue the touch screen on the top of the electronic paper body and place it in the fixture for 20 seconds, and Its peripheral edges can be further fixed by, for example, glued paper;

[0032] 2) Vacuum heating and bonding: Take out the bonded and fixed product from the fixture, place it in a vacuum furnace and heat and bond at 20Pa and 65°C for 40 minutes;

[0033] 3) Defective product inspection: check whether there are air bubbles, foreign objects, etc. in the heat-bonded product. If so, disassemble the product, tear off the heat-bonded COF adhesive film, and return to step 1) to repeat Bonding; if the inspection is qualified, then enter the next UV curing step;

[0034] 4) UV curing: put the product bonded by vacuum heating in step 3) in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com