Two-component nano-polymer sand-fixing material and sand-fixing method

A technology of nano-polymer and sand-fixing method, which is applied to two-component nano-polymer sand-fixing materials and the field of sand-fixing, can solve the problems of easy cracking and poor impact resistance, and achieves strong durability, good water stability and moderate water absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

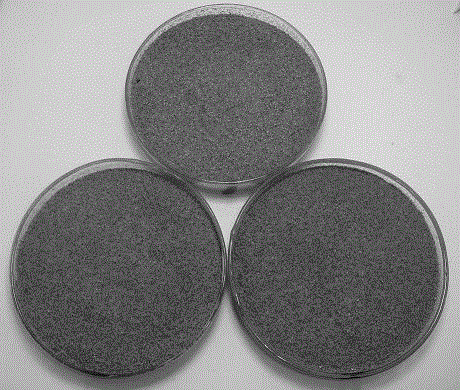

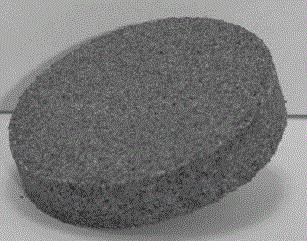

Image

Examples

Embodiment 1

[0026] Example 1 A two-component nano-polymer sand-fixing material, which is composed of component A composed of polyvinyl alcohol-epoxy resin blend modified by inorganic nanoparticles and component B composed of polyurethane prepolymer. in

[0027] Component A refers to dispersing nano-silica with a particle size of 20 nanometers in N,N-dimethylformamide, heating to 80°C, and adding polyethylene with a number-average molecular weight of 160,000 under stirring. Alcohol, after the polyvinyl alcohol is completely dissolved, add epoxy resin and cross-linking agent DMP30 to it in turn, continue to stir for 1 hour and then cool down to room temperature. The ratio of nano-silica to N,N-dimethylformamide is 0.01kg: 400mL, the ratio of nano-silica to polyvinyl alcohol is 0.01kg: 0.15kg, and the ratio of nano-silica to epoxy resin is 0.01kg: 0.25kg; the ratio of nano-silica to DMP30 is 0.01kg: 0.01kg.

[0028] Component B is to add castor oil to N,N-dimethylformamide, heat to 40°C, a...

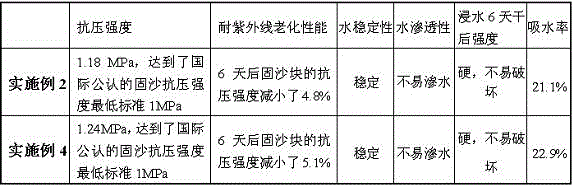

Embodiment 2

[0030] Example 2 Two-component nano-polymer sand-fixing material, which is composed of component A composed of polyvinyl alcohol-epoxy resin blend modified by inorganic nanoparticles and component B composed of polyurethane prepolymer. in

[0031] Component A refers to dispersing nano-silica with a particle size of 30 nanometers in N,N-dimethylformamide, heating to 100°C, and adding polyethylene with a number-average molecular weight of 140,000 under stirring. Alcohol, after the polyvinyl alcohol is completely dissolved, add epoxy resin and crosslinking agent DMP30 to it in turn, continue to stir for 3 hours and then cool down to room temperature. The ratio of nano-silica to N,N-dimethylformamide is 0.02kg: 250mL, the ratio of nano-silica to polyvinyl alcohol is 0.02kg: 0.2kg, and the ratio of nano-silica to epoxy resin is 0.02kg: 0.22kg; the ratio of nano-silica to DMP30 is 0.02kg: 0.02kg.

[0032] Component B is to add castor oil to N,N-dimethylformamide, heat to 60°C, add...

Embodiment 3

[0034] Example 3 Two-component nano-polymer sand-fixing material, which is composed of component A composed of polyvinyl alcohol-epoxy resin blend modified by inorganic nanoparticles and component B composed of polyurethane prepolymer. in

[0035] Component A refers to dispersing nano-silica with a particle size of 50 nanometers in N,N-dimethylformamide, heating to 90°C, and adding polyethylene with a number-average molecular weight of 170,000 under stirring. Alcohol, after the polyvinyl alcohol is completely dissolved, add epoxy resin and cross-linking agent DMP30 to it in turn, continue to stir for 2 hours and then cool down to room temperature. The ratio of nano-silica to N,N-dimethylformamide is 0.03kg: 350mL, the ratio of nano-silica to polyvinyl alcohol is 0.03kg: 0.25kg, and the ratio of nano-silica to epoxy resin is 0.03kg: 0.15kg; the ratio of nano-silica to DMP30 is 0.03kg: 0.01kg.

[0036] Component B is to add castor oil to N,N-dimethylformamide, heat to 50°C, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com