Automatic Edge Sewing Machine

A sewing machine, automatic technology, applied in sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of low edge-to-edge accuracy, increase working time, reduce production efficiency, etc., achieve a high degree of automation, improve production efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

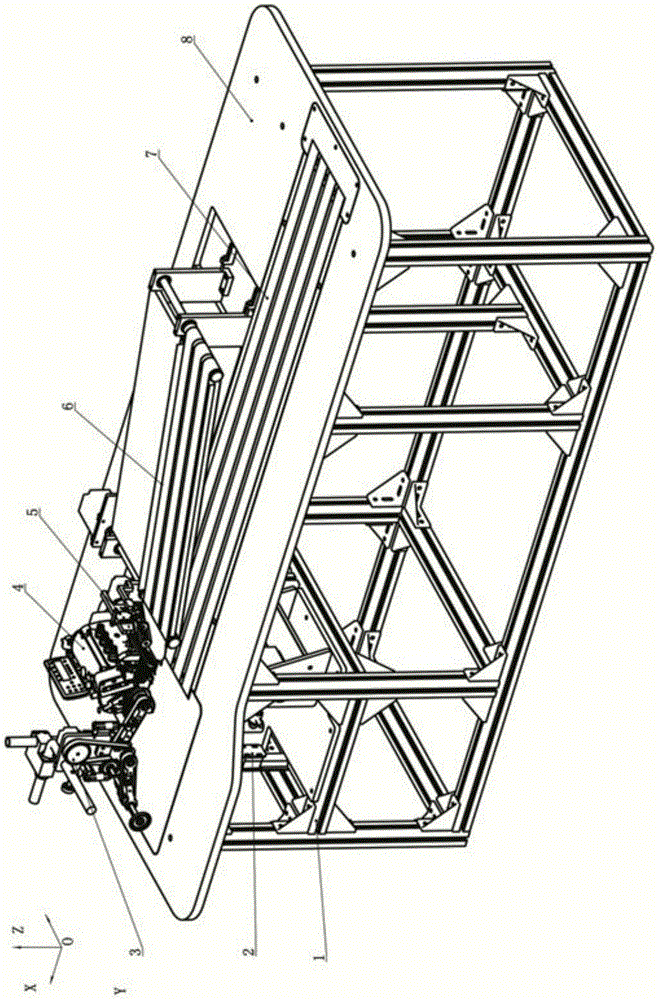

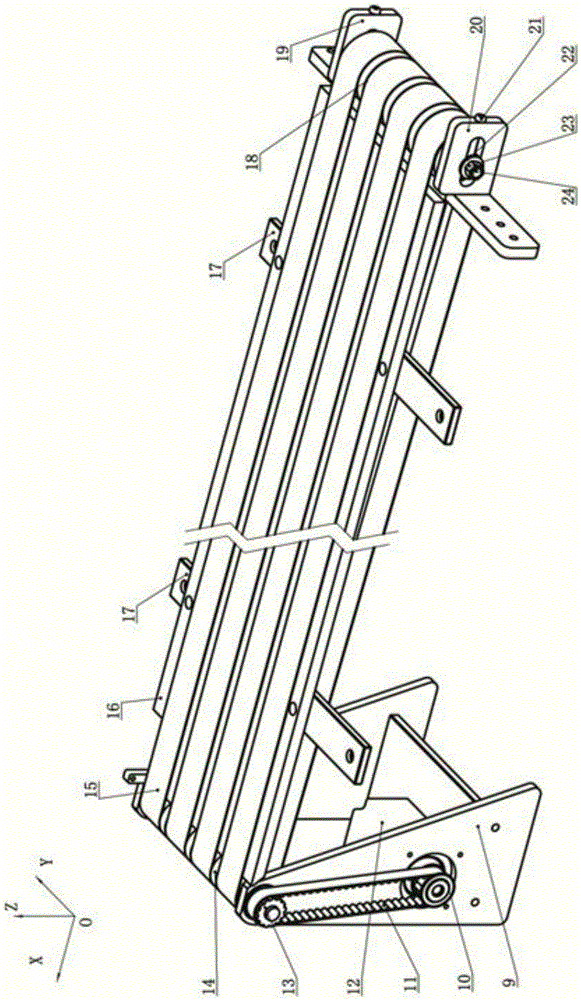

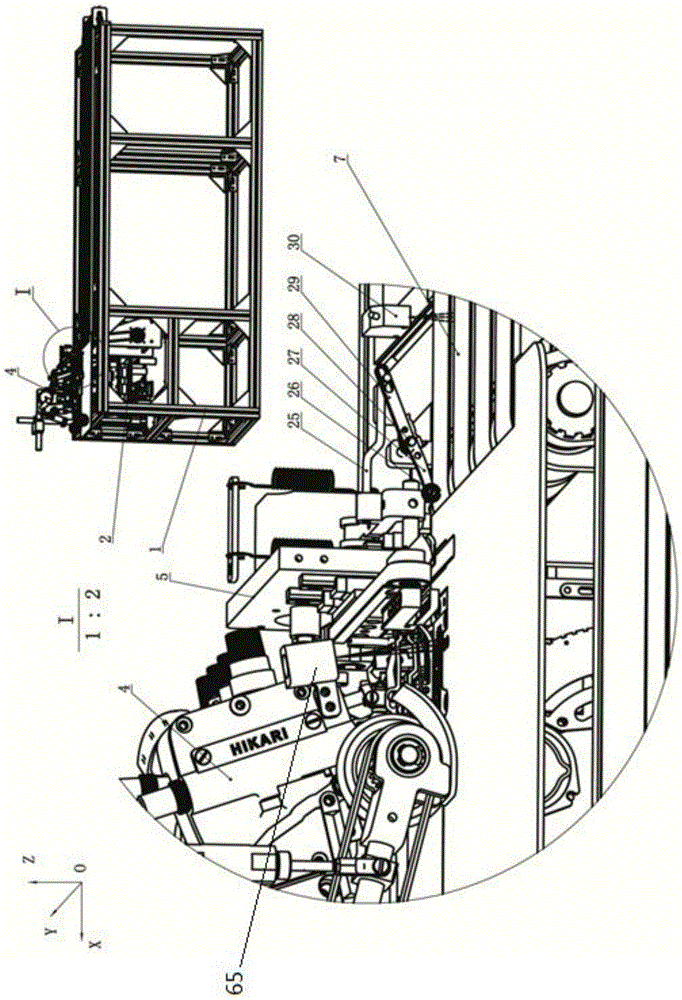

[0035] Embodiment (one): the embodiment of double-layer cloth sewing.

[0036] join Figure 1-7 , the lower floor feeding motor 12 rotates, driving the driving pulley 10 to rotate, and the driving pulley 10, the synchronous belt 11 and the driven pulley 13 rotate together, driving the lower belt shaft 13 to rotate, the lower belt shaft 13, the feeding belt 15 and the feeding The lower belt two shafts 18 rotate together, and the lower cloth sheet B1 is placed on the feeding belt 15 in the cloth edge placement area, and the lower belt two shafts 18 of the feeding drive the cloth sheet to move together by static friction. When the lower photoelectric eye 30 detects the cloth piece B1, the feedback signal of the lower layer photoelectric eye 30 controls the electromagnetic valve to open, and the lower blowing pipe 64 starts to blow air, and the air flow will make the front edge of the lower cloth piece B1 close to the feeding belt 15, and the front edge of the cloth piece B1 will ...

Embodiment ( 2

[0047] Embodiment (two): the implementation manner of single-layer fabric hemming

[0048] The lower floor feeding motor 12 rotates to drive the driving pulley 10 to rotate, and the driving pulley 10, the synchronous belt 11 and the driven pulley 13 rotate together, driving the lower feeding belt shaft 13 to rotate, the feeding lower belt shaft 13, the feeding belt 15 and the feeding lower belt The two belt shafts 18 rotate together, and the lower cloth sheet B1 is placed on the feeding belt 15 in the cloth edge placement area, and the lower belt two shafts 18 of the feeding drive the cloth sheet to move together by static friction. When the lower photoelectric eye 30 detects the cloth piece B1, the feedback signal of the lower layer photoelectric eye 30 controls the solenoid valve to open, and the lower blowing pipe 64 starts to blow air, and the air flow will make the front edge of the lower cloth piece B1 close to the feeding belt 14, and the front edge of the cloth piece B1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com