Trolley for receiving and dispatching oil and gas pipeline detection equipment

A technology for oil and natural gas and pipeline detection, applied in mechanical equipment, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of oil and natural gas leakage, unsafe transmission and reception of detection equipment, etc., and achieves strong applicability, simple structure, The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

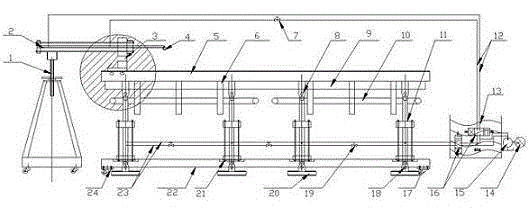

[0016] see figure 1 , 2 , which are structural schematic diagrams of an oil and gas pipeline detection transceiver equipment trolley according to the present invention. As shown in the figure: it is assembled by a carrying device, a booster device, a power system and a moving device.

[0017] Its specific structure is as follows:

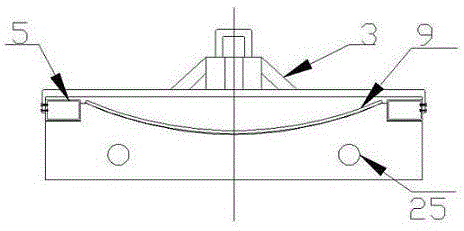

[0018] The bearing device includes an arc bearing plate 9, 4-10 bottom reinforcing ribs 6, 2-4 bearing beams 5, 4-8 supporting hydraulic cylinders 11, 2-4 base beams 22 and 4-8 The base bearing platform 20; wherein: the arc bearing plate 9 and the bottom reinforcement rib 6 are connected together by welding, the bottom reinforcement rib 6 and the load beam 5 are welded together, and the load beam 5 is connected to the supporting hydraulic cylinder 11 through the first pin 8 Together, the supporting hydraulic cylinder 11 and the base beam 22 are connected together by the first screw 21 , and the supporting hydraulic cylinder 11 and the base bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com