Servo rope type hot forging piece axial dimension detection apparatus

A technology of axial dimension and detection device, applied in the direction of measuring device, instrument, etc., can solve the problems of high cost, low precision, poor working environment, etc., and achieve the effect of reducing processing amount, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

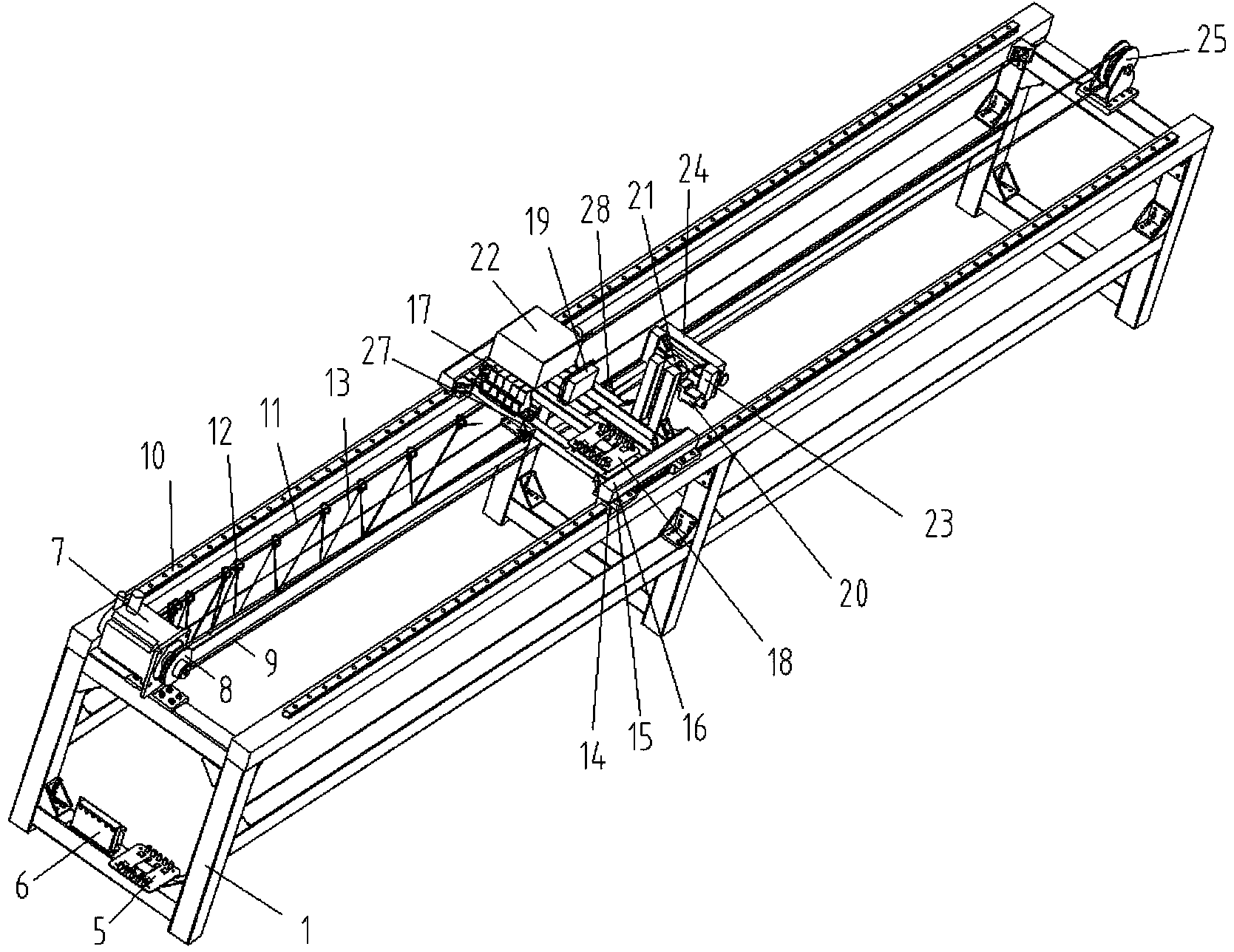

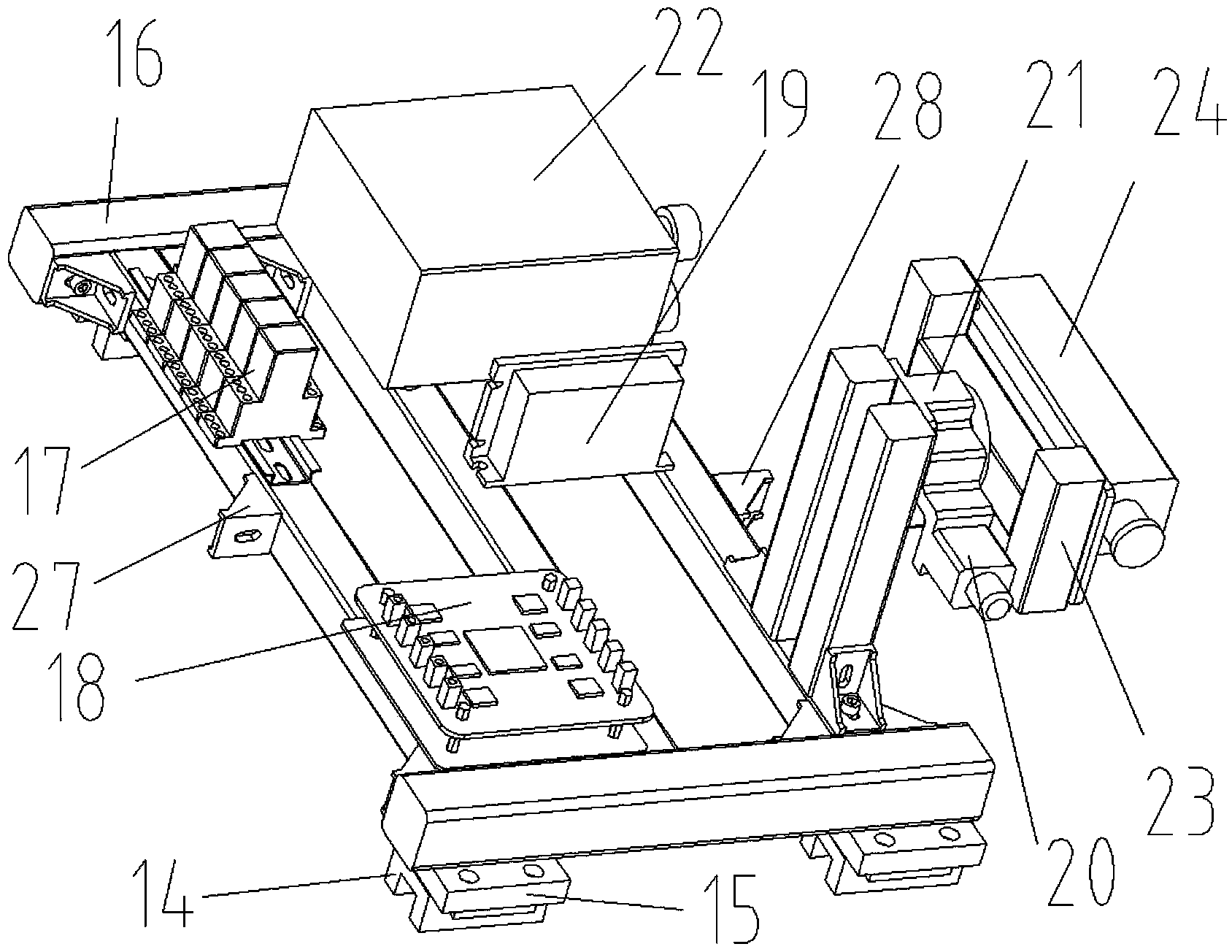

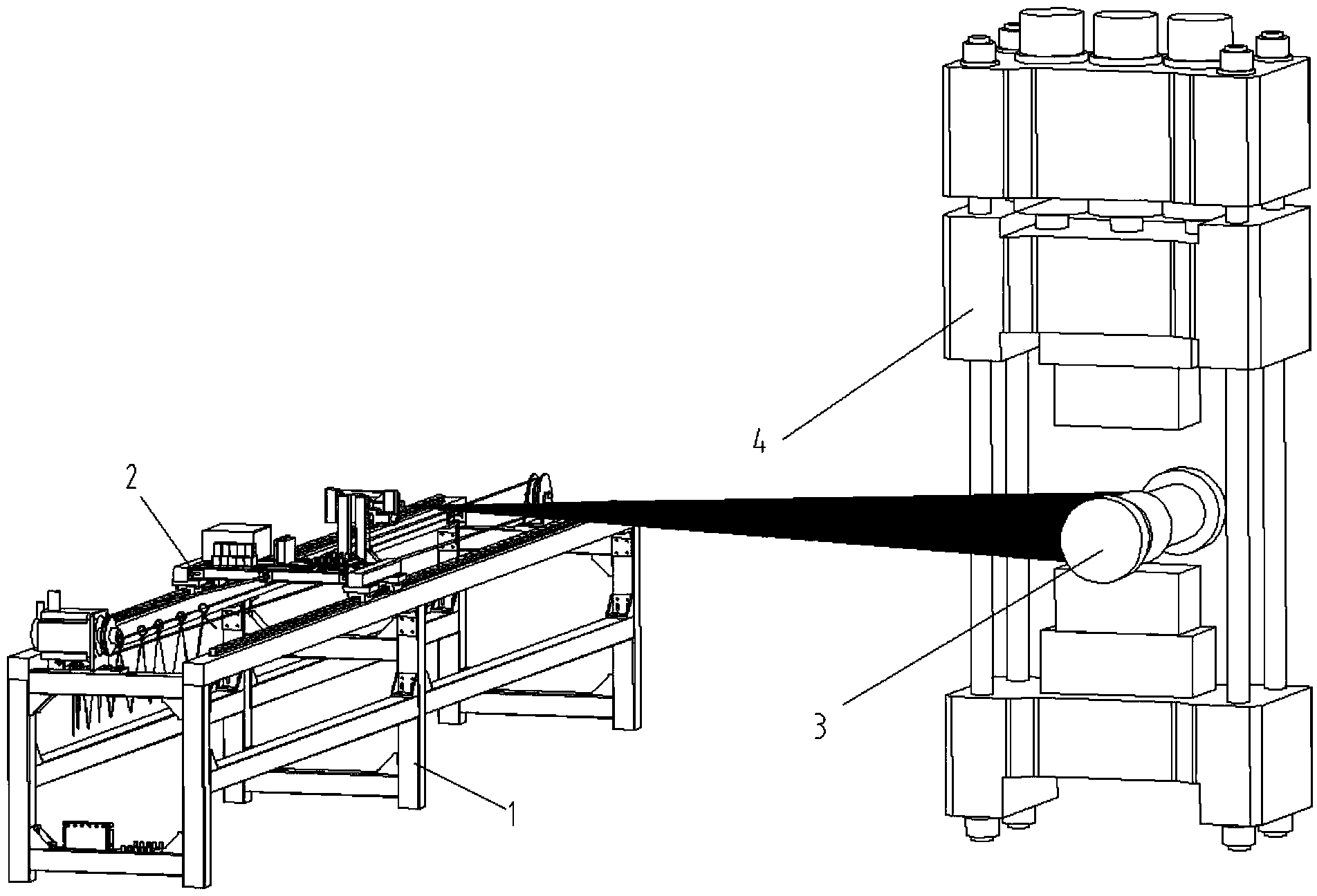

[0021] refer to figure 1 , image 3 , a servo rope-type axial dimension detection device for hot forgings, including a mobile trolley 2, the mobile trolley 2 is arranged on a linear guide rail 10, the linear guide rail 10 is fixed on an industrial aluminum profile support 1, and is axially parallel to the forging press 4, The dolly 2 is driven by the dolly drive system.

[0022] refer to figure 1 , Figure 4 , the mobile trolley drive system includes a first control circuit board 5, the input / output end of the first control circuit board 5 is wirelessly connected with the total control module 26, and the output end of the first control circuit board 5 is input to the main motor servo driver 6 The output end of the main motor servo driver 6 is connected to the control end of the AC servo main motor 7, the output shaft of the AC servo main motor 7 is connected to the sheave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com