Design method of variable cross-section beam of automobile body in white

A technology of variable-section beam and design method, applied in the direction of calculation, special data processing application, instrument, etc., can solve the problem of synchronous optimization without variable-section plate, and achieve the reduction of body lightweight design, the realization of manufacturing cost, and the improvement and optimization of structural performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

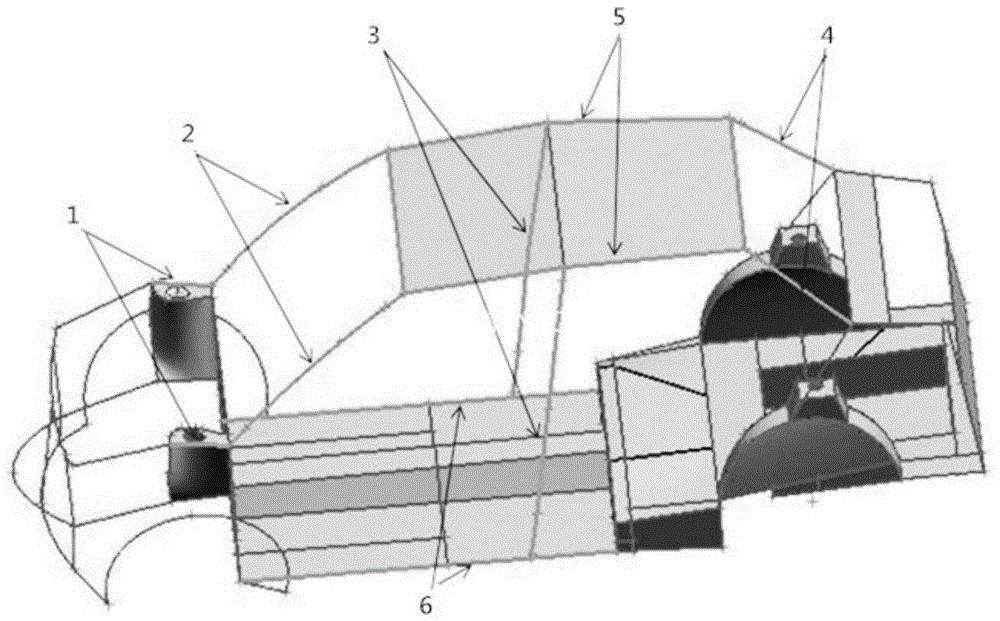

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

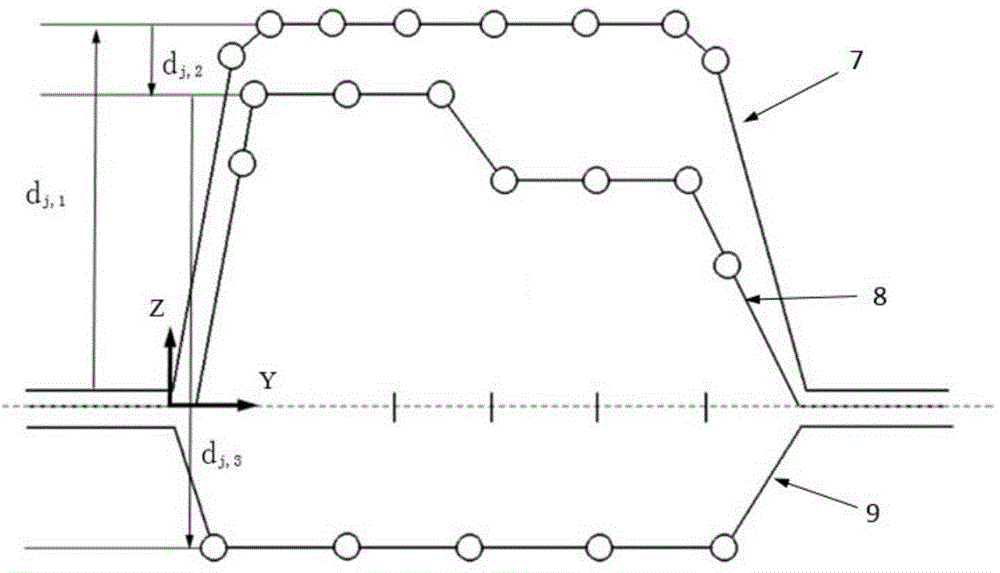

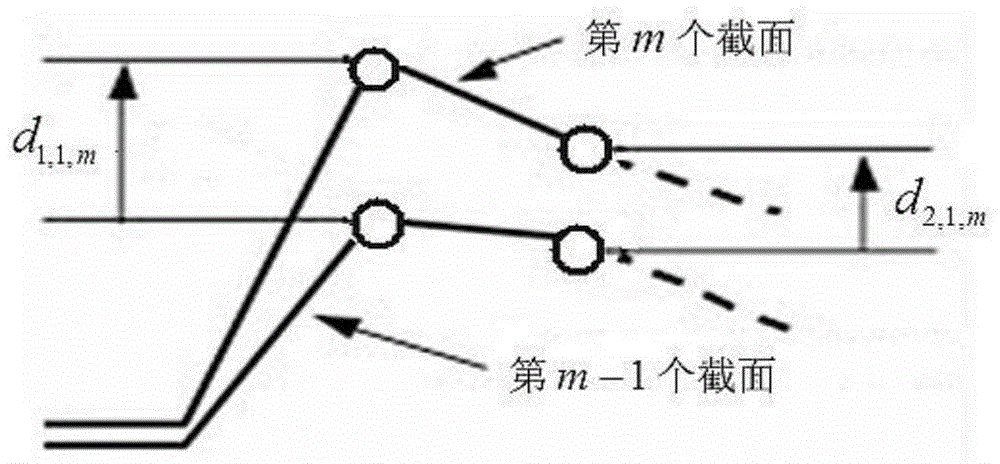

[0043] The present invention arranges the individual control points in the variable-section beam of the body-in-white according to the section form and optimization conditions. The two connection points of the beam section are taken as the y-axis, and the straight line perpendicular to the y-axis passing through one of the connection points is set as the z-axis to establish the beam section. Local coordinates, with the intersection of the y-axis and the z-axis as the origin of the coordinates; when controlling the shape of the beam section, the y-coordinates of the control points of the outer plate are projected onto the inner plate and the reinforced plate respectively, among which, the outer plate, the inner plate and the reinforced plate There are multiple control points on the board; keep the y-coordinate of the control points on the outer board unchanged, and chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com