Steel structure fire protection design method based on fire heat release rate measurement

A technology of heat release rate and protection design, applied in calculation, material heat development, special data processing application, etc., can solve problems that cannot truly reflect the impact of fire resistance, many calculation steps, long calculation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

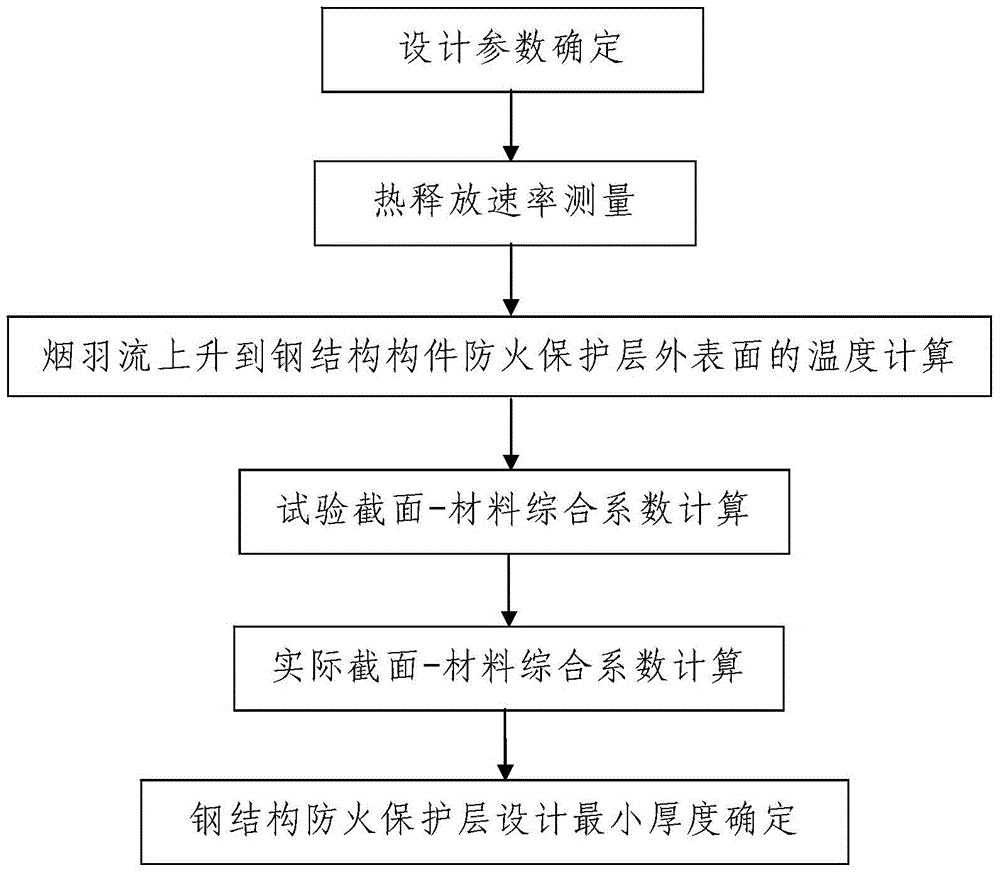

[0046] Such as figure 1 A fire protection design method for steel structures based on the measurement of fire heat release rate is shown, including the following steps:

[0047] Step 1. Determination of design parameters: according to the design fire resistance rating of the building where the steel structural member needs to be designed for fire protection, determine the fire resistance limit n of the steel structural member; and combine the steel structural member in the building where it is located The layout position in the building is determined by the height z of the steel structural member above the fire source below it; wherein, the unit of n is h (hour), and the unit of z is m.

[0048] Wherein, the designed fire resistance level of the building is the pre-designed fire resistance level of the building. Fireproof rating, Fireproof endurance rating, is a grading scale to measure the fire resistance of buildings. The fire resistance rating of buildings is one of the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com