X-ray diffractometer in situ battery accessory, heating device, cooling device and measuring method

An X-ray and diffractometer technology, applied in the field of battery measurement, can solve the problems of many assembly parts, complex design, and high price, and achieve good air tightness, ensure electrical conductivity, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

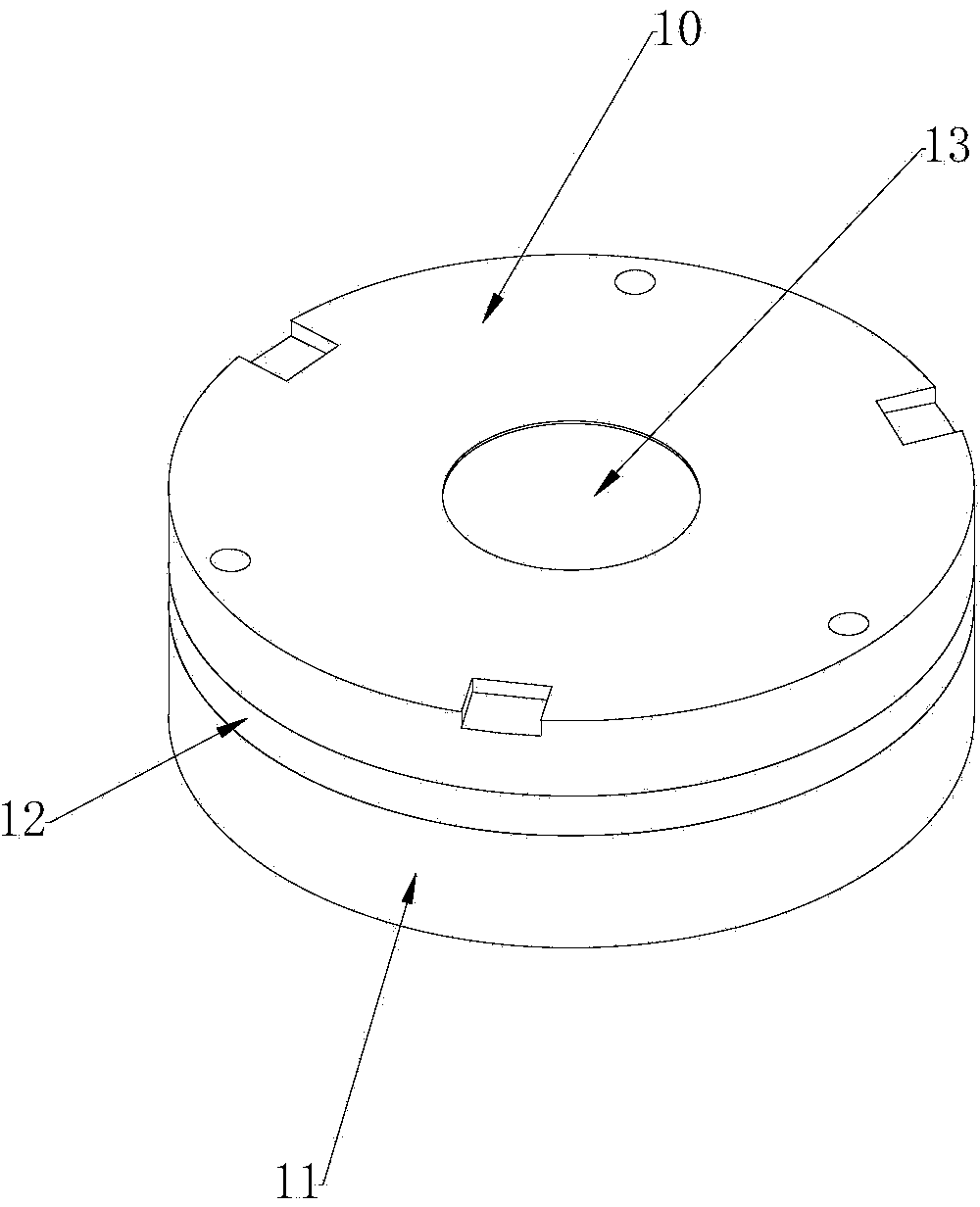

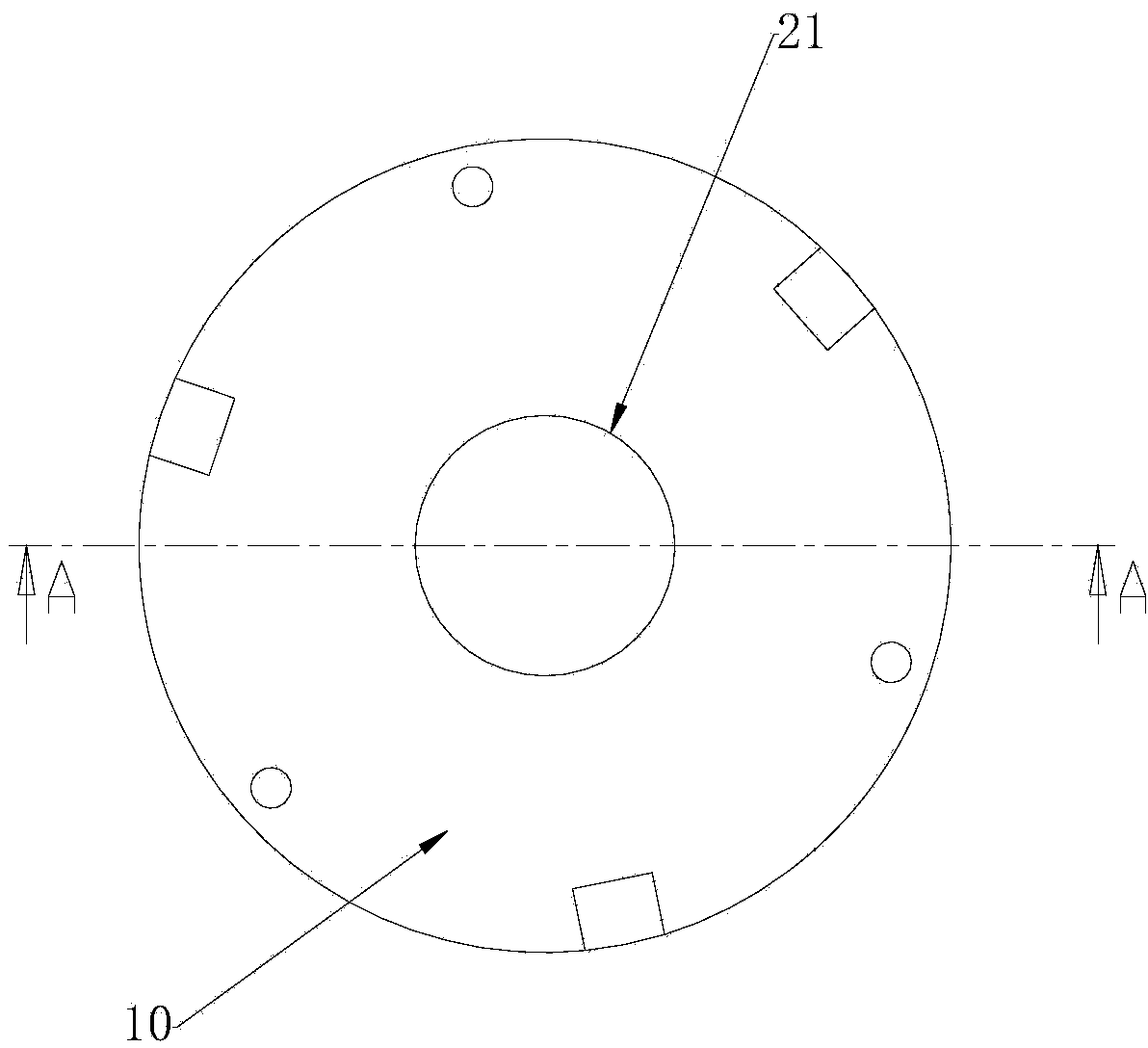

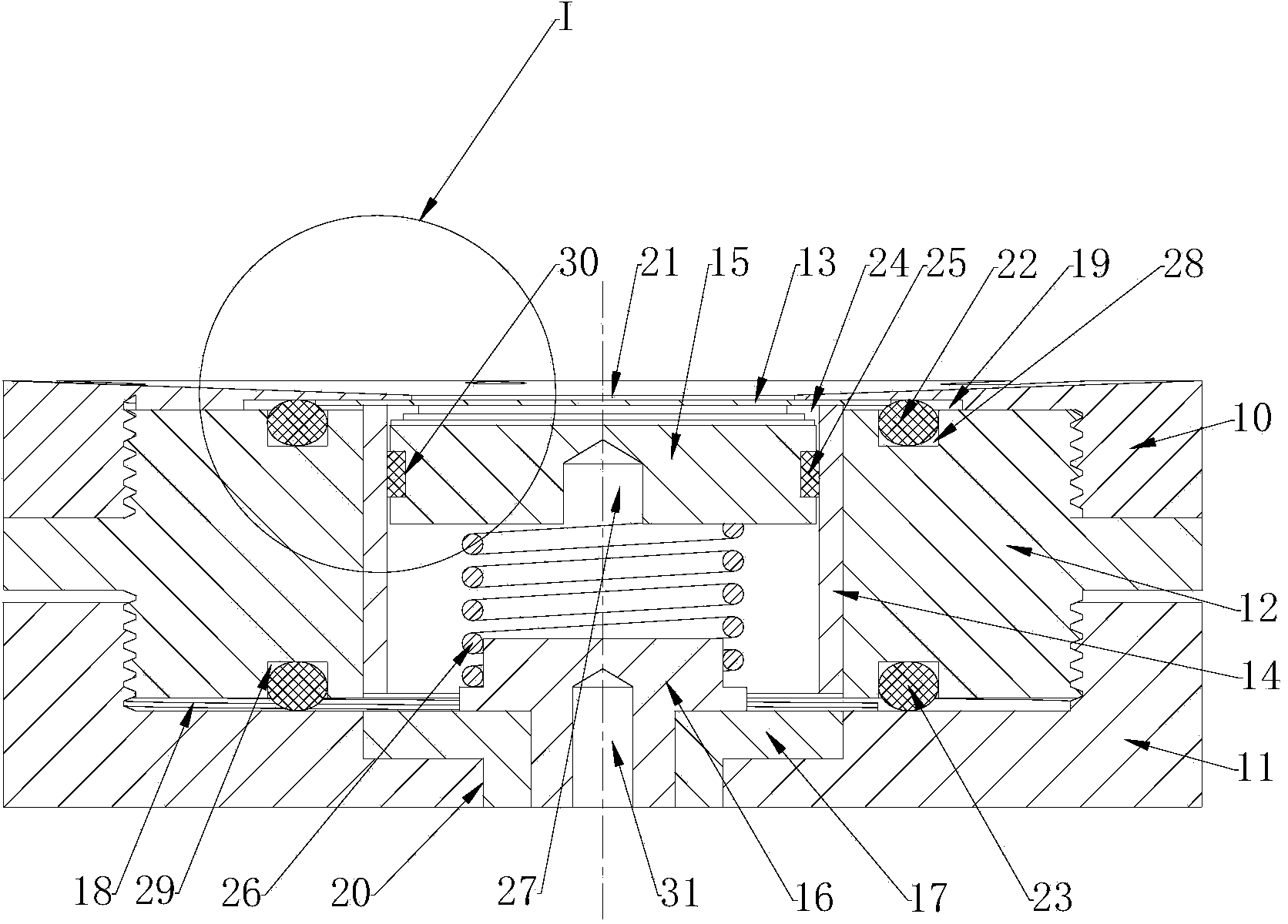

[0044] This embodiment provides an in-situ battery accessory for an X-ray diffractometer, such as Figure 1-4 As shown, it includes an upper top cover 10 , a lower top cover 11 , a central bolt 12 , a beryllium window 13 , a central cavity insulator 14 , a negative conductive seal 15 , a central electrode 16 and a central insulator 17 .

[0045] to combine Figure 5 As shown, the upper end surface of the lower top cover 11 is provided with a first threaded hole 18, and the lower end surface of the upper top cover 10 is provided with a second threaded hole 19, the first threaded hole 18 and the second threaded hole 19 are blind holes , the upper end of the central bolt 12 is installed in the second threaded hole 19 , and the lower end of the central bolt 12 is installed in the first threaded hole 18 . The upper top cover 10, the lower top cover 11 and the central bolt 12 are all made of conductive materials, such as stainless steel.

[0046] A first sealing ring 22 is provide...

Embodiment 2

[0056] This embodiment provides a heating device for an in-situ battery accessory of an X-ray diffractometer, such as Figure 8 As shown, it includes a first housing 50 and a first upper cover 51 . Both the first casing 50 and the first upper cover 51 are made of steel. The first casing 50 is in a tubular shape with the lower end closing the upper opening. The first upper cover 51 is fixedly installed on the first casing 50 , and the first upper cover 51 closes the upper opening of the first casing 50 . A sealing ring can be installed between the first upper cover 51 and the first housing 50 . A first window 52 and a second window 53 are opened on the side wall of the first housing 50 , the first window 52 is opposite to the second window 53 , and both the first window 52 and the second window 53 are rectangular holes. Both the first window 52 and the second window 53 are sealed by polyimide tape.

[0057] A heater and a temperature sensor are fixedly installed in the first...

Embodiment 3

[0060] Such as Figure 6 As shown, this embodiment provides a cooling device for an in-situ battery accessory of an X-ray diffractometer, including a second casing 70 and a second upper cover 71 . The second housing 70 and the second upper cover 71 are made of polytetrafluoroethylene or similar materials with low thermal conductivity (such as plexiglass, polypropylene, polyethylene, polystyrene, etc.). The second housing 70 is in the shape of a tube with the lower end closing the upper opening. The second upper cover 71 is fixedly mounted on the second housing 70. The second upper cover 71 closes the upper opening of the second housing 70. Between the second upper cover 71 and A sealing ring may be installed between the second shells 70 . The side wall of the second housing 70 is provided with a third window 72 and a fourth window 73, the third window 72 and the fourth window 73 are oppositely arranged, the third window 72 and the fourth window 73 are rectangular holes, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com