Hole coupling and tuning device for utilizing sliding piston to conduct tuning

A sliding piston and tuning device technology, applied in the microwave field, can solve the problems of non-simulation design value of coupling degree, inconsistent design size, impure excitation mode, etc., and achieves the effects of good strength stability, impure solution mode, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

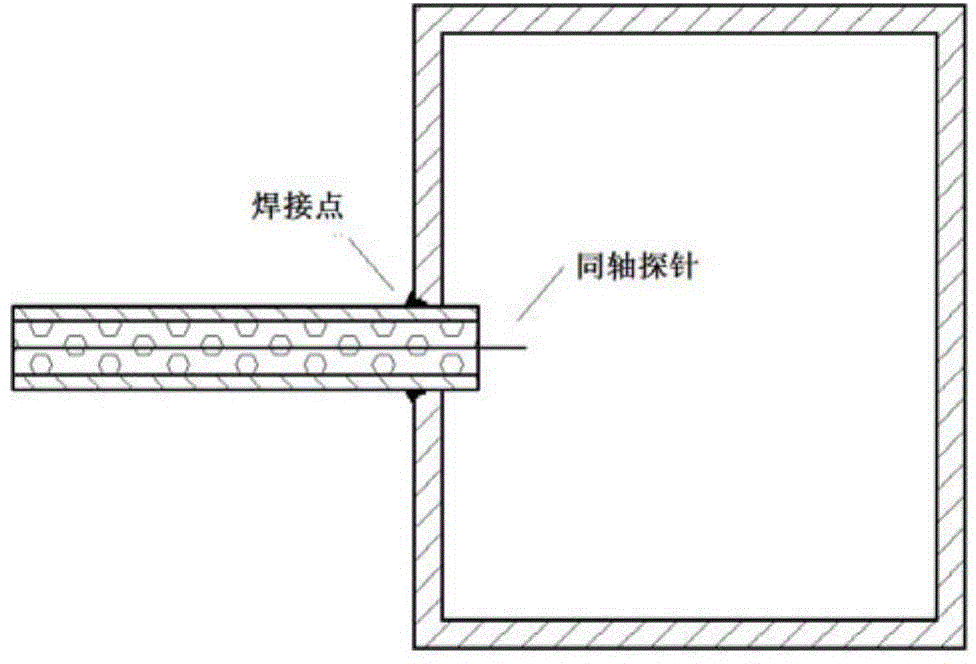

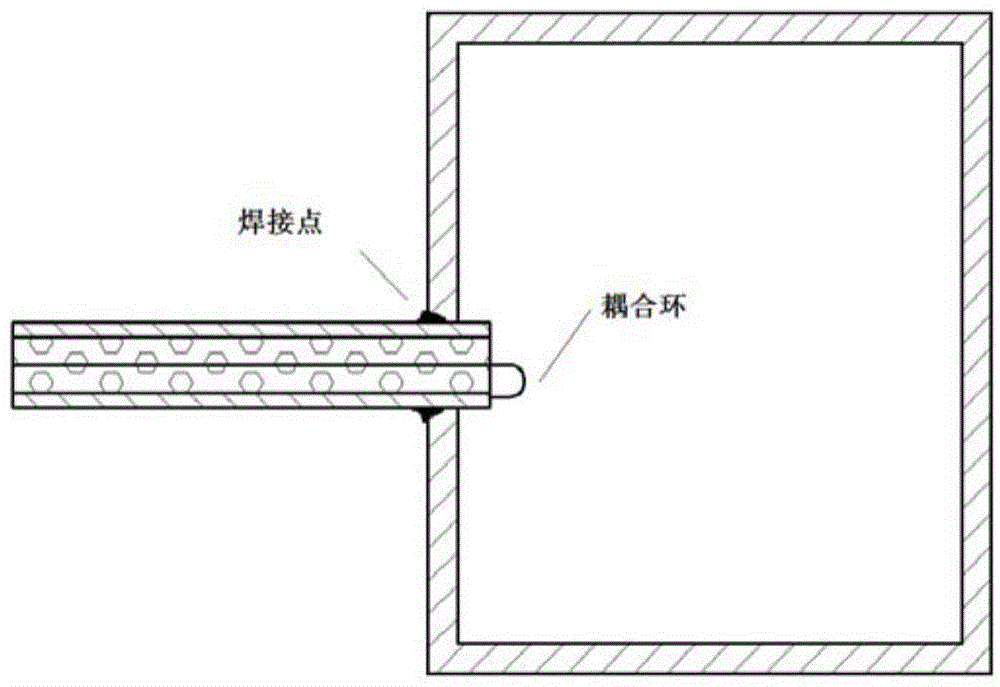

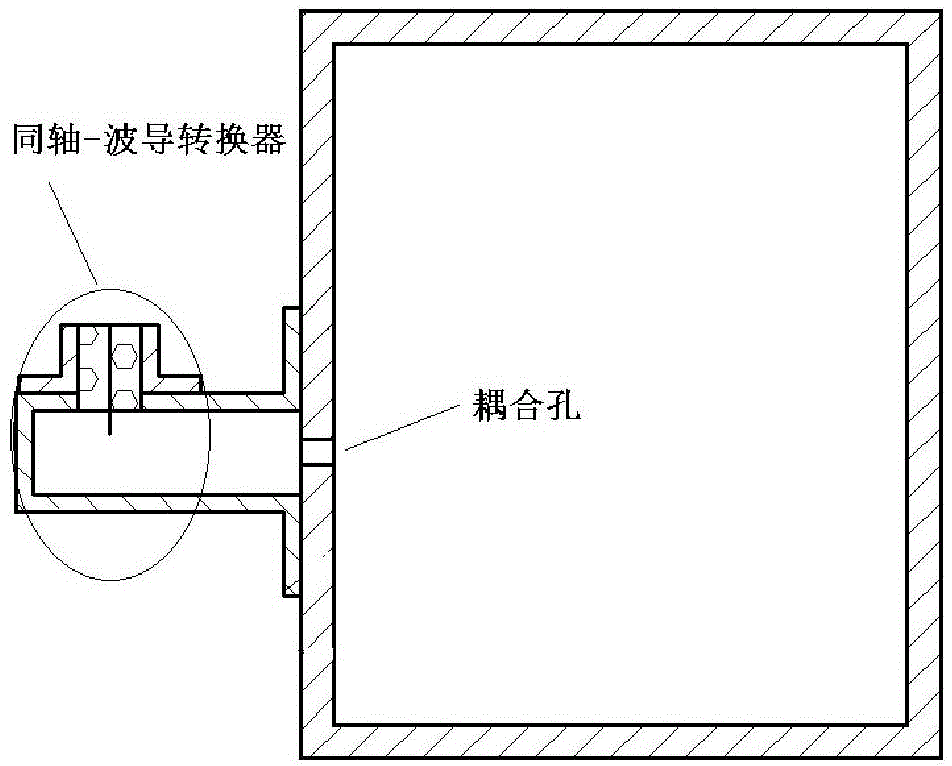

[0019] In order to overcome the problem that the existing probe coupling and ring coupling are difficult to realize and the hole coupling mode is impure when adjusting the coupling coefficient, the invention provides a tuning device that facilitates tuning of the coupling coefficient. The device is based on the transmission line matching technology, adopts the structure of the sliding piston to cooperate with the coupling hole, and realizes the coupling coefficient of the tuning hole coupling by changing the position of the sliding piston to achieve the required coupling coefficient. This device makes good use of the advantages of hole coupling and solves the problem of its mode impurity, and can be easily applied to resonant cavities that require accurate adjustment of coupling coefficients, especially those with more than one coupling coefficient that need to be accurately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com