Method for preparing tofu by using lactobacillus plantarum fermentation liquor to curdle

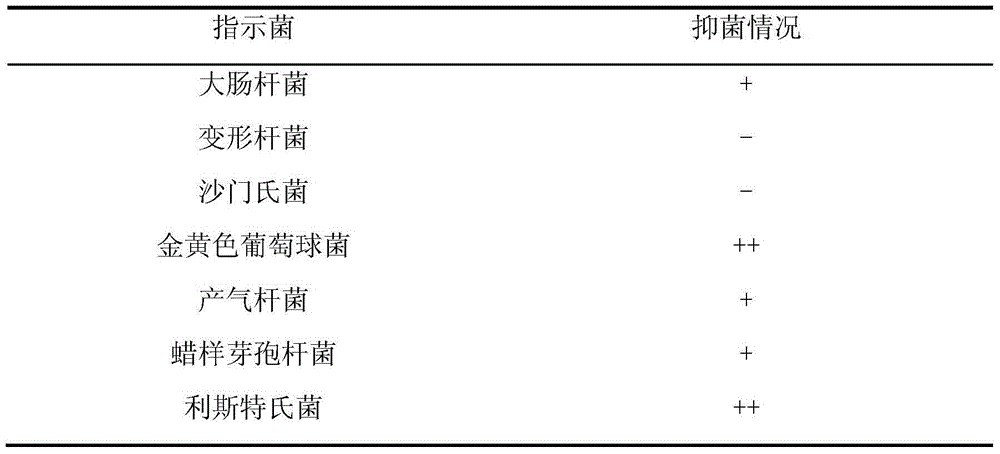

A technology of Lactobacillus plantarum and fermentation broth, applied in dairy products, applications, cheese substitutes, etc., can solve the problems of unstable coagulation performance, unclear coagulation mechanism, and high cost, and achieves inhibition of the growth of miscellaneous bacteria and good water holding capacity. , the effect of long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

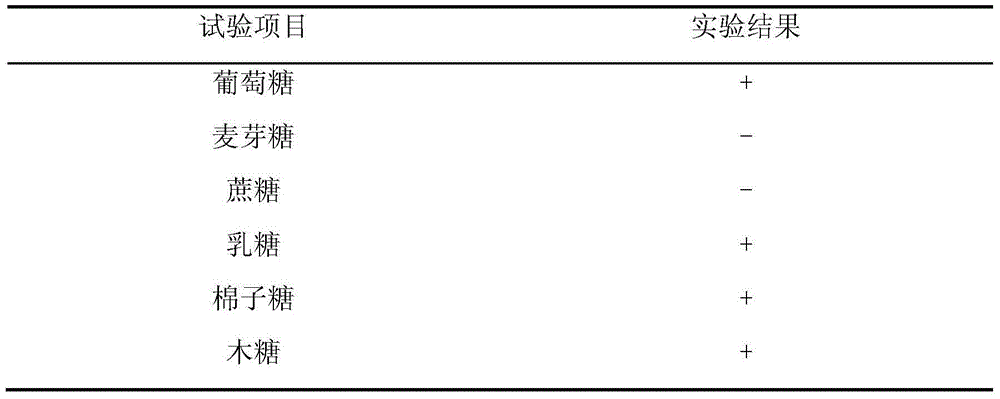

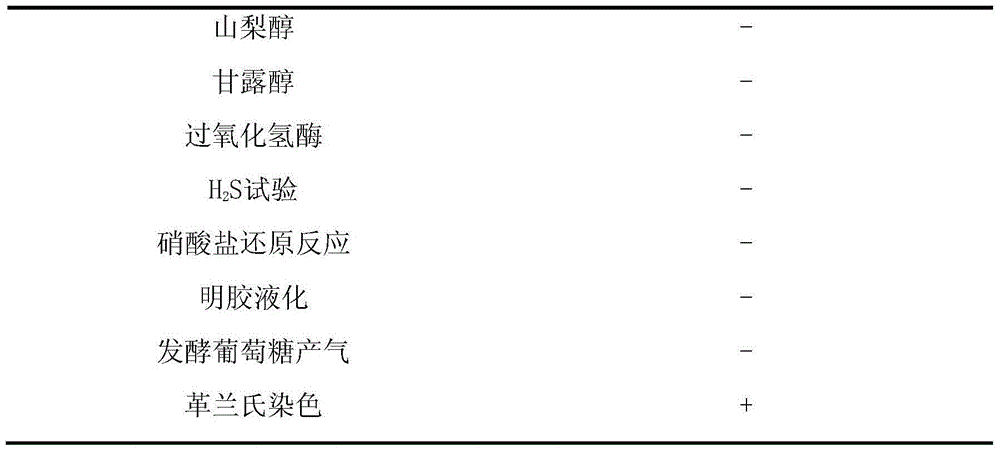

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of described lactobacillus plantarum fermented liquid is as follows:

[0047] Lactobacillus plantarum Lact.chili.6 was activated on the slant of MRS solid medium for 24-48h at 37°C, then transferred to the supernatant liquid filtered during the briquetting of tofu, and expanded at 30-37°C for 24-48h. The pH value of the Lactobacillus plantarum fermentation broth is 4.5-5.0.

[0048] After the soybeans are selected, removed and cleaned, they are soaked in water. The ratio of material to water during soaking is 1:2. The soaking time: when the room temperature is greater than or equal to 20°C, soak for 5 hours; After refining and filtering with LZ350 type vertical shaft refiner, burn the pulp for 8 minutes at 100°C; , poured into hot soybean milk, and let it stand for 3 minutes; and then proceeded with free slurry treatment: put the fermented liquid of Lactobacillus plantarum with a weight of 2% of the weight of soybean milk after flushing into a sm...

Embodiment 2

[0052] The preparation method of described lactobacillus plantarum fermented liquid is as follows:

[0053] Lactobacillus plantarum Lact.chili.6 was activated on the slant of MRS solid medium for 24-48h at 37°C, then transferred to the supernatant liquid filtered during the briquetting of tofu, and expanded at 30-37°C for 24-48h. The pH value of the Lactobacillus plantarum fermentation broth is 4.5-5.0.

[0054]After the soybeans are selected, removed and cleaned, they are soaked in water. The ratio of material to water during soaking is 1:3. The soaking time: when the room temperature is greater than or equal to 20°C, soak for 6 hours; After refining and filtering with LZ350 vertical shaft refiner, burn the pulp at 100°C for 10 minutes and then perform pulping treatment: take the fermented liquid of Lactobacillus plantarum with a weight of 1.5% of the weight of soybean milk after burning from a height of 1.2m from the liquid surface of the heated soybean milk , poured into h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com