Stalk pellet flat die forming device

A molding device and granule technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of high energy consumption and large ineffective friction at the holes and bridges on the molding die, so as to achieve low comprehensive energy consumption, The effect of reducing the axial length and reducing the energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

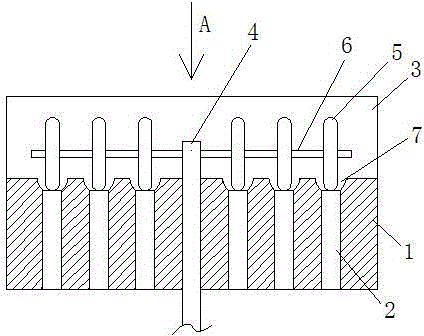

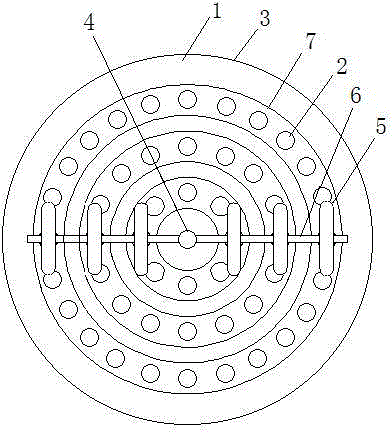

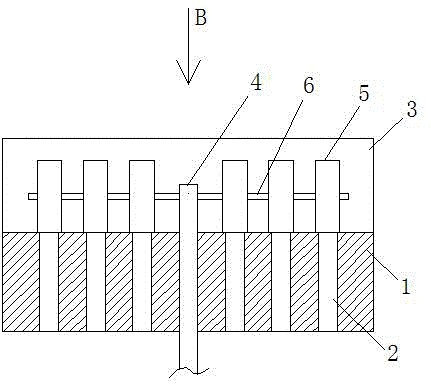

[0022] Such as figure 1 with figure 2 The straw granule flat die molding device shown includes a feeding chamber 3, a molding die 1 arranged at the bottom of the feeding chamber 3, a rotating shaft 4 driven by a power mechanism passing through the molding die 1, and a diameter of the feeding chamber from the rotating shaft 4 to the outside. At least two transmission rods 6 extending toward each transmission rod 6 are rotatably connected to each transmission rod 6 with an equal number and corresponding pressure rollers 5. The forming die 1 is also provided with concentric rollers on the circumference of the pressure roller 5 revolving with the rotating shaft 4. Arc-shaped grooves 7, each arc-shaped groove 7 is evenly arranged with a plurality of forming holes 2 located on the circumference of the pressure roller 5 revolving with the rotating shaft 4, the interval between adjacent forming holes 2 is less than 5mm, the interval is the hole bridge, and its length The smaller it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com