Knuckle reconfigurable robot unit module

A technology for reconfiguring robots and unit modules, applied in the field of robots, can solve the problems of complex structure, high development cost, inconvenient popularization and promotion, etc., and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

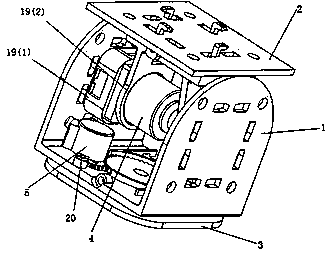

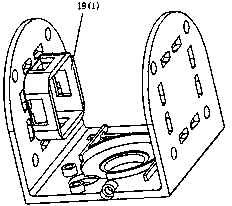

[0040] like figure 1 , figure 2 As shown, the claw-type reconfigurable robot unit module is a cuboid of 100mm*100mm*112mm, including an outer U-shaped frame 1, a U-shaped inner frame 2, and a rotating Base substrate 3, a spindle turning stepping reduction motor 4, a base rotating stepping reduction motor 5, a stepping reduction motor 14, an active connection mechanism, three passive connection surfaces, and a set of inner and outer frame connectors, namely the motor bracket 19 , rotating shaft 17 and stamping bearing 18.

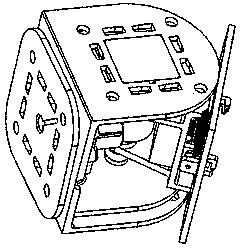

[0041] This unit module can realize the relative rotation between the outer U-shaped frame 1 and the U-shaped inner frame 2 under the drive of the spindle turning stepping gear motor 4, and the maximum angle is ±90°, such as figure 2 shown, for the figure 1 Basically, the main shaft turns over and the stepping reduction motor 4 drives the inner frame 2 to rotate clockwise around the outer U-shaped frame 1.

[0042] like Figure 5 , Image 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com