Anti-ablation layer on graphite surface and preparation method thereof

An anti-ablation and graphite technology, which is applied in the field of ultra-high temperature ceramic modified high-temperature oxidation-resistant ablation layer on the surface of graphite and its preparation, and in the field of anti-ablation layer on graphite surface and its preparation, which can solve the problem of damage to the mechanical properties of graphite matrix, protection Problems such as limited layer thickness and large graphite porosity achieve the effect of low cost, large thickness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

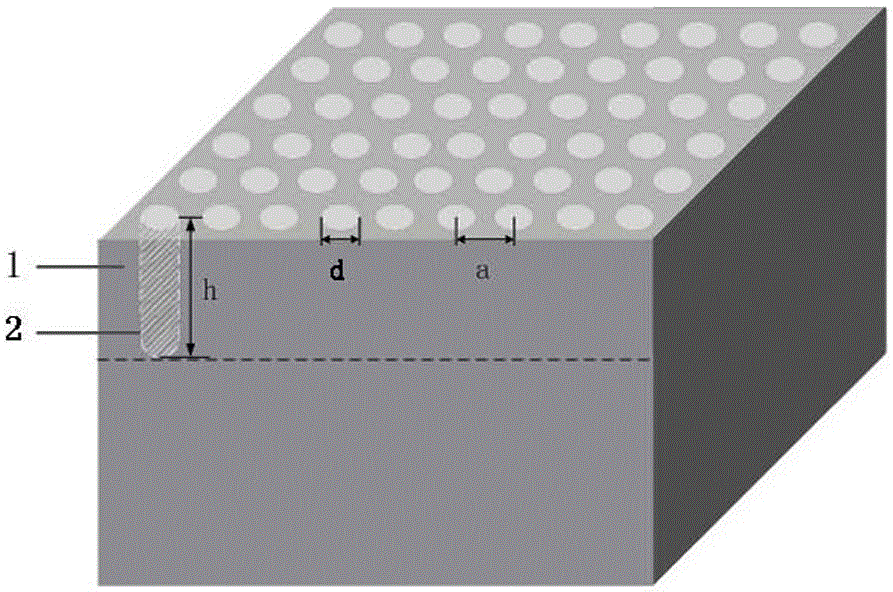

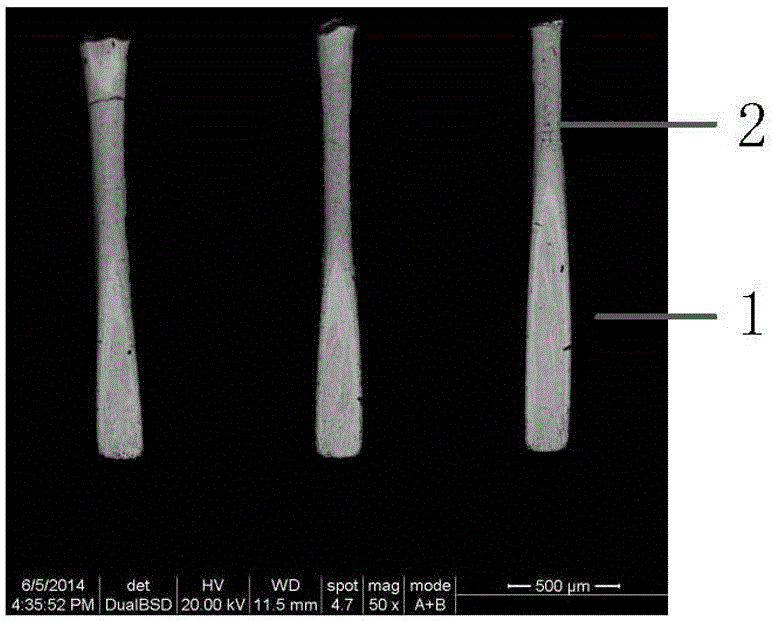

[0038] A kind of graphite surface anti-ablation layer of the present invention, such as figure 1 As shown, the anti-ablation layer on the graphite surface is composed of a graphite surface substrate 1 and ultra-high temperature ceramic columns 2 uniformly and regularly distributed (specifically, equidistant distribution) in the graphite surface substrate 1 . The composition of ultra-high temperature ceramic column 2 is ZrB 2 -SiC-ZrC. The ultra-high temperature ceramic column 2 is in the shape of a cylinder and is perpendicular to the surface of the graphite surface substrate 1 (ie, the graphite surface). The diameter d of the ultra-high temperature ceramic column 2 is 0.1 mm, the height h is 1 mm (that is, the aspect ratio is 10), and the distance a between the centers of adjacent ultra-high temperature ceramic columns 2 is 0.2 mm. The thickness of the anti-ablation layer on the graphite surface is equal to the height of the ultra-high temperature ceramic 2, which is 1mm. ...

Embodiment 2

[0048] A kind of graphite surface anti-ablation layer of the present invention, such as figure 1 As shown, the anti-ablation layer on the graphite surface is composed of a graphite surface substrate 1 and ultra-high temperature ceramic pillars 2 equidistantly distributed in the graphite surface substrate 1 . The composition of the ultra-high temperature ceramic column 2 is HfC-SiC. The ultra-high temperature ceramic column 2 is in the shape of a cylinder, perpendicular to the surface of the graphite surface substrate 1 (that is, the graphite surface). The diameter d of the ultra-high temperature ceramic column 2 is 0.2mm, and the height h is 2mm (that is, the aspect ratio is 10). The distance a between the centers of adjacent ultra-high temperature ceramic pillars 2 is 0.4 mm. The thickness of the anti-ablation layer on the graphite surface is equal to the height of the ultra-high temperature ceramic 2, which is 2 mm. Graphite surface substrate 1 is the porous surface layer ...

Embodiment 3

[0059] A kind of graphite surface anti-ablation layer of the present invention, such as figure 1 As shown, the anti-ablation layer on the graphite surface is composed of a graphite surface substrate 1 and ultra-high temperature ceramic pillars 2 equidistantly distributed in the graphite surface substrate 1 . The composition of ultra-high temperature ceramic column 2 is HfC-SiC-ZrB 2 -ZrC-TaC. The ultra-high temperature ceramic column 2 is in the shape of a cylinder, perpendicular to the surface of the graphite surface substrate 1, the diameter d of the ultra-high temperature ceramic column 2 is 0.4 mm, and the height h is 4 mm (that is, the aspect ratio is 10). The adjacent ultra-high temperature ceramic column The center distance a between 2 is 0.8mm. The thickness of the anti-ablation layer on the graphite surface is equal to the height of the ultra-high temperature ceramic 2, which is 4mm. Graphite surface substrate 1 is the porous surface layer of graphite substrate, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com