Polymer-based conductive elastomer and preparation method thereof

A technology of polymers and elastomers, applied in the field of designing conductive polymer composite materials, to achieve the effects of improved tensile strength, good elasticity and resilience, and improved elasticity and resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

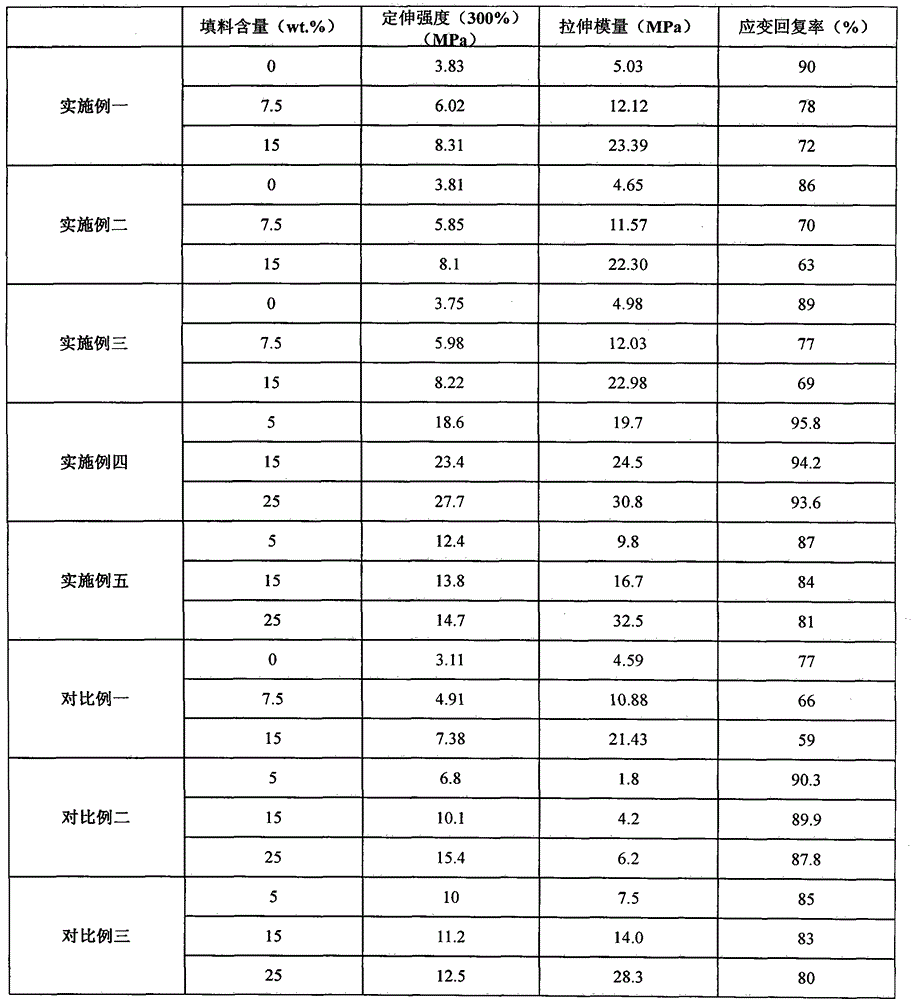

Embodiment 1

[0032] The vulcanizing agent is 3phr dicumyl peroxide (DCP), blended with ethylene octene copolymer (POE) for 1min, statically vulcanized at 170°C and 10MPa for 15min, and cooled for 1min. After being pulverized by a high-speed pulverizer with a rotating speed of 25,000 rpm for 3 minutes, cross-linked particles with a particle size of 40-60 mesh (about 250-420 microns) were screened out with a sample sieve.

[0033] Under the conditions of 150°C and 50rpm, the POE and mass fraction were respectively 0, 2.5, 5, 7.5, 10, 12.5, 15, 17.5 in a torque rheometer (XSS-300, produced by Shanghai Qingji Mold Factory). The multi-walled carbon nanotubes (MWCNT) blended for 5 minutes to obtain a masterbatch; then the above-mentioned cross-linked particles with a content of 75wt.% were added, and the blending was continued for 5 minutes. After blending, hot press at 150°C and 10 MPa for 5 minutes, and cool to prepare the crosslinked particle / POE / MWCNT-A conductive elastomer.

Embodiment 2

[0035] The vulcanizing agent is 3phr dicumyl peroxide (DCP), blended with ethylene octene copolymer (POE) for 1min, statically vulcanized at 170°C and 10MPa for 15min, and cooled for 1min. After being pulverized by a high-speed pulverizer with a rotating speed of 25,000 rpm for 3 minutes, cross-linked particles with a particle size of 40-60 mesh (about 250-420 microns) were screened out with a sample sieve.

[0036] Under the conditions of 150°C and 50rpm, the POE and mass fraction were respectively 0, 2.5, 5, 7.5, 10, 12.5, 15, 17.5 in a torque rheometer (XSS-300, produced by Shanghai Qingji Mold Factory). The multi-walled carbon nanotubes (MWCNT) blended for 5 minutes to obtain a masterbatch; then the above-mentioned cross-linked particles with a content of 25 wt.% were added, and the blending was continued for 5 minutes. After blending, hot press at 150°C and 10 MPa for 5 minutes, and cool to obtain a crosslinked particle / POE / MWCNT-B conductive elastomer.

Embodiment 3

[0038] The vulcanizing agent is 3phr dicumyl peroxide (DCP), blended with ethylene octene copolymer (POE) for 1min, statically vulcanized at 170°C and 10MPa for 15min, and cooled for 1min. After being pulverized by a high-speed pulverizer with a rotating speed of 25,000 rpm for 3 minutes, cross-linked particles with a particle size of 20-40 mesh (about 420-850 microns) were screened out with a sampling sieve.

[0039] Under the conditions of 150°C and 50rpm, the POE and mass fraction were respectively 0, 2.5, 5, 7.5, 10, 12.5, 15, 17.5 in a torque rheometer (XSS-300, produced by Shanghai Qingji Mold Factory). The multi-walled carbon nanotubes (MWCNT) blended for 5 minutes to obtain a masterbatch; then the above-mentioned cross-linked particles with a content of 75wt.% were added, and the blending was continued for 5 minutes. After blending, heat-press at 150°C and 10 MPa for 5 minutes, and cool to obtain a cross-linked particle / POE / MWCNT-C conductive elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com