Low-oil-mist flame-retardant emulsified cutting oil and preparation method thereof

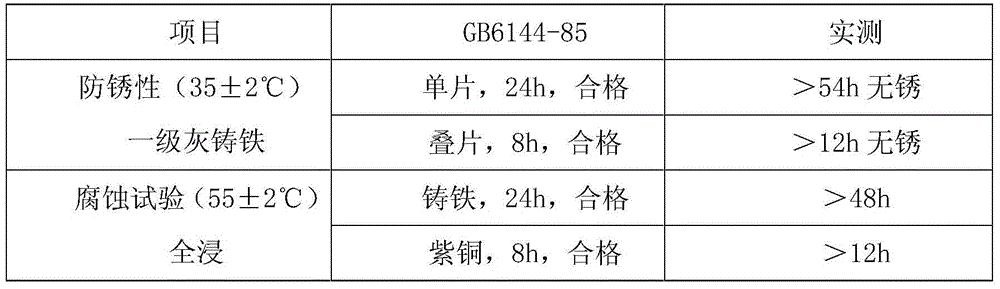

A flame retardant, cutting oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor production environment, high use cost, cooling, lack of oil mist odor, etc., to achieve low production cost, protection of metal cut surfaces , No irritating odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through specific examples.

[0014] A low-oil mist flame-retardant emulsified cutting oil, made of the following raw materials in parts by weight (kg): No. 10 aviation hydraulic oil 30, epoxy soybean oil 4, soybean oil 11, pine tar oil 1, triphenyl phosphite 10. Sorbitan monooleate 9, tea saponin 0.5, ammonium polyphosphate 2, magnesium hydroxide 3, propylene glycol 4, polyisobutylene 1.5, modified waste engine oil 9;

[0015] The modified waste engine oil is prepared from the following raw materials in parts by weight (kg): waste engine oil 40, waste kerosene 11, activated clay 2, sulfonated castor oil 2, acrylic resin emulsion 4, alcohol ester dodeca 1, trihydroxy Methylpropane triacrylate 2, Span 801, dodecenyl succinic acid diethanolamide 1, cyclohexylamine 1, glycerin 2, antimony trioxide 2, graphite milk 4; the preparation method is to first mix waste engine oil, After mixing waste kerosene, heat up to 120°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com