A continuous multi-stage cooling and dewaxing method and system for grease

A technology for dewaxing and fat removal, which is applied in the direction of edible oil/fat, fat oil/fat refining, and fat production. It can solve the problems of slow filtration speed, unstable product quality, and low production efficiency, and achieve fast filtration speed and high product quality. The effect of stabilizing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

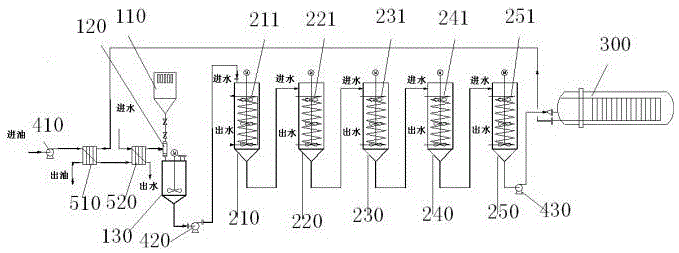

[0027] The present invention provides a continuous multi-stage cooling and dewaxing method and system for grease. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

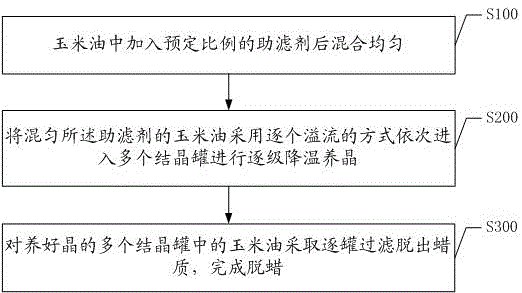

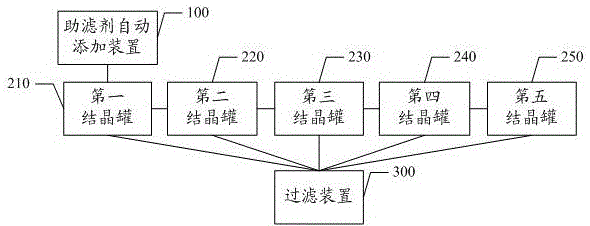

[0028] Such as figure 1 A continuous multistage cooling and dewaxing method for grease shown, wherein the method comprises the following steps:

[0029] S100, adding a predetermined proportion of filter aid to the corn oil and mixing evenly.

[0030] Wherein, before the step S100, the temperature of the corn oil is lowered to 12-15° C. through a heat exchanger. By lowering the temperature when the oil enters, the crystal growth time in the subsequent crystal growth tank can be shortened.

[0031] In the continuous multi-stage cooling dewaxing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com