A non-vacuum step-through fast selenization device and a selenization method realized by using it

A non-vacuum, selenization technology, applied in chemical instruments and methods, crystal growth, coating, etc., can solve the problem that the improvement of the uniformity of the flow field in the process chamber does not achieve the desired effect, and cannot meet the uniformity of large-area battery manufacturing problems. Affecting problems such as rapid online large-scale production and application, to achieve the effect of preventing external gas from entering, reducing consumption, and high electrothermal conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The non-vacuum step-by-step fast selenization method comprises the steps:

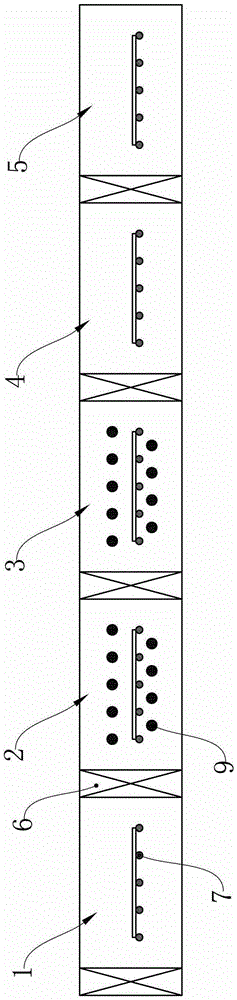

[0049] (1) Fill the loading chamber 1, heating chamber 2, heat preservation chamber 3, cooling chamber 4 and unloading chamber 5 with inert gas nitrogen, the internal air pressure is higher than the external air pressure, and ensure that the loading chamber 1, cooling chamber 4 and unloading chamber 5 The internal air pressure is equal and greater than the heating chamber 2 and the heat preservation chamber 3 with the same pressure as the heating chamber 2;

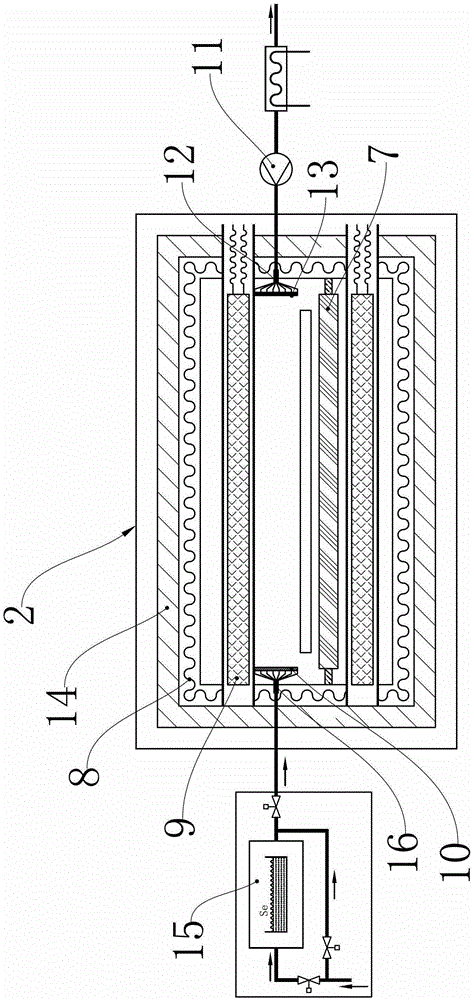

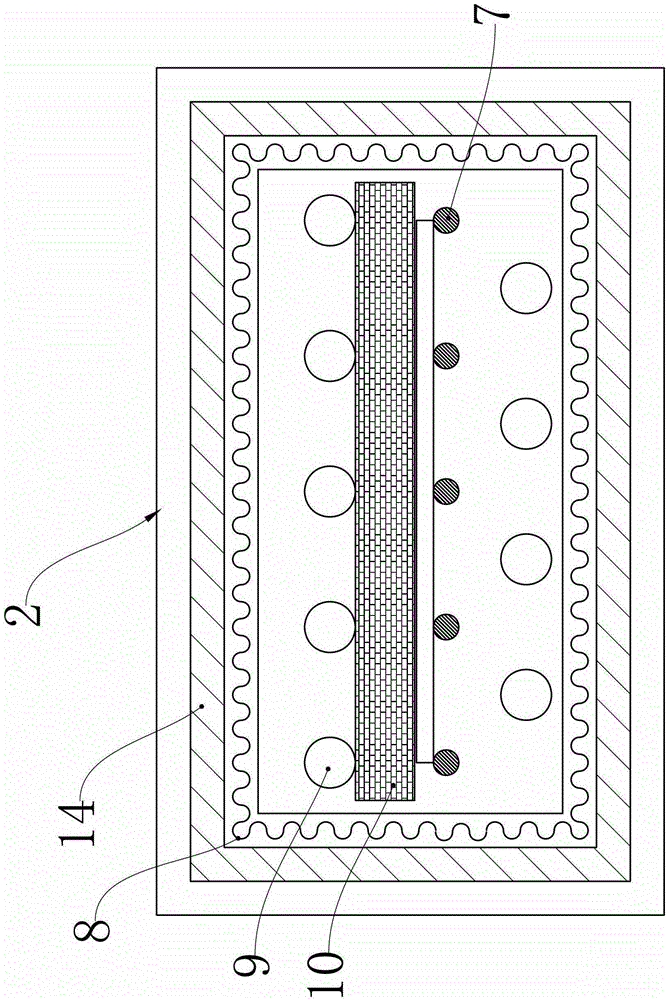

[0050] (2) Preheating the solid selenium vapor of the process gas, using the blast unit and the air extraction unit to realize the forced circulation of the process gas inside the heating chamber 2 and the heat preservation chamber 3, and using the electric heating wire 8 to heat the heat chamber 2 and the heat preservation chamber The temperature of the heat insulation layer 14 of the chamber 3 is 240°C, and the temperature in the chamber ...

Embodiment 2

[0054] The non-vacuum step-by-step fast selenization method comprises the steps:

[0055] (1) Fill the loading chamber 1, heating chamber 2, heat preservation chamber 3, cooling chamber 4 and unloading chamber 5 with inert gas argon, the internal pressure is higher than the external pressure, and ensure that the loading chamber 1, cooling chamber 4 and unloading chamber The air pressure in 5 is equal and greater than that of the heating chamber 2 and the heat preservation chamber 3 with the same pressure as the heating chamber 2;

[0056] (2) Preheat the process gas hydrogen selenide, utilize the blast unit and the air extraction unit to realize the forced circulation of the process gas inside the heating chamber 2 and the heat preservation chamber 3, and use the electric heating wire 8 to heat to the heat preservation chamber 2 and the heat preservation chamber The temperature of the heat insulation layer 14 of the cavity 3 is 250°C, and the temperature in the cavity of the h...

Embodiment 3

[0060] The non-vacuum step-by-step fast selenization method comprises the steps:

[0061] (1) Fill the loading chamber 1, heating chamber 2, heat preservation chamber 3, cooling chamber 4 and unloading chamber 5 with inert gas nitrogen, the internal air pressure is higher than the external air pressure, and ensure that the loading chamber 1, cooling chamber 4 and unloading chamber 5 The internal air pressure is equal and greater than the heating chamber 2 and the heat preservation chamber 3 with the same pressure as the heating chamber 2;

[0062] (2) Preheating the solid selenium vapor of the process gas, using the blast unit and the air extraction unit to realize the forced circulation of the process gas inside the heating chamber 2 and the heat preservation chamber 3, and using the electric heating wire 8 to heat the heat chamber 2 and the heat preservation chamber The temperature of the heat insulation layer 14 of the chamber 3 is 260°C, and the temperature in the chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com