Molten iron desiliconization agent, pouring device and molten iron desiliconization pretreatment method

A desiliconizing agent and molten iron technology, which is used in the field of molten iron desiliconization in the metallurgical industry, can solve the problems of long time desiliconization treatment, large temperature loss in the treatment process, and large equipment investment, so as to achieve less equipment investment and better separation of slag and iron. , the effect of large processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A molten iron desiliconization agent, the composition weight percentage of the desiliconization agent is: iron oxide scale (rolled iron oxide scale waste produced in the steel rolling production process): 75-80%, lime powder: 12-15%, fluorite powder: 5% ~8%, the particle size of this desiliconization agent is 2~5mm.

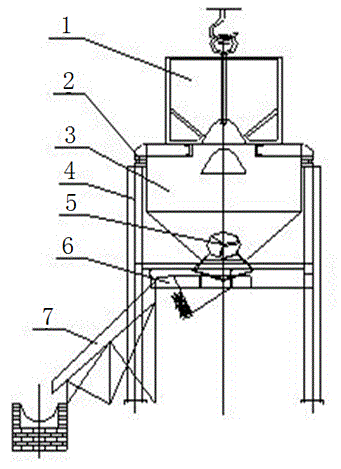

[0023] like figure 1 A kind of material throwing device shown, it comprises bracket 4, the material bin 3 that is installed on the top of bracket 4, it is characterized in that: the inlet of material bin 3 top is connected with the outlet of material storage 1, and material bin The top of 3 is provided with a load cell 2, and the outlet of the material bin 3 is provided with a discharge valve 5. A vibrating feeder 6 is arranged below the discharge port of the material bin 3, and the vibrating feeder 6 is installed on the support 4, and a swinging feeder 7 is provided at the discharge port of the vibrating feeder 6.

[0024] A method for pretreatment of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com