Groove testing rack for underwater inspection of diversion tunnel door gate groove of hydropower station and construction method

A technology for test tanks and hydropower stations, which is applied in hydropower stations, water conservancy projects, hydroelectric power generation, etc., and can solve the inspection restrictions and problems of inspection equipment and instruments that cannot be carried out, cannot be dismantled, and door slots and bottom sills are worn or scoured. impact and other issues, to achieve the effect of simple structure, simplified construction process, and strong resistance to water impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

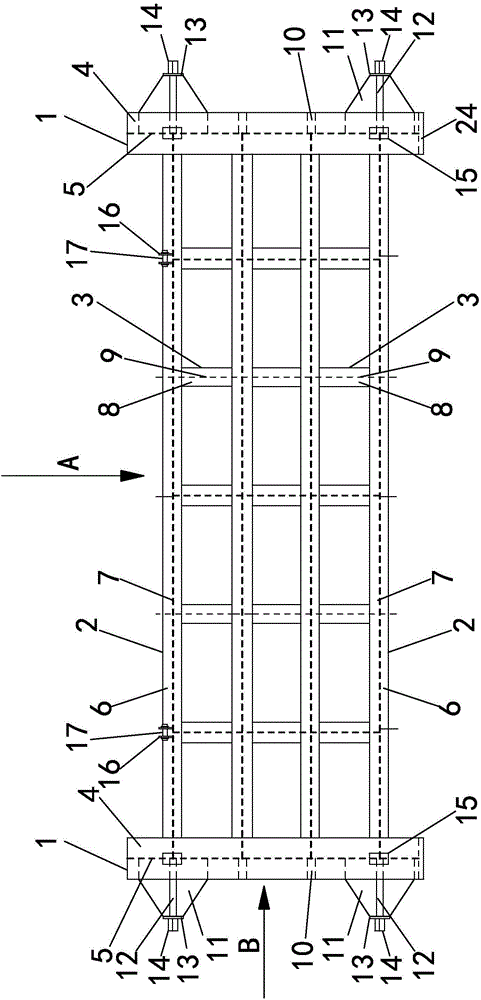

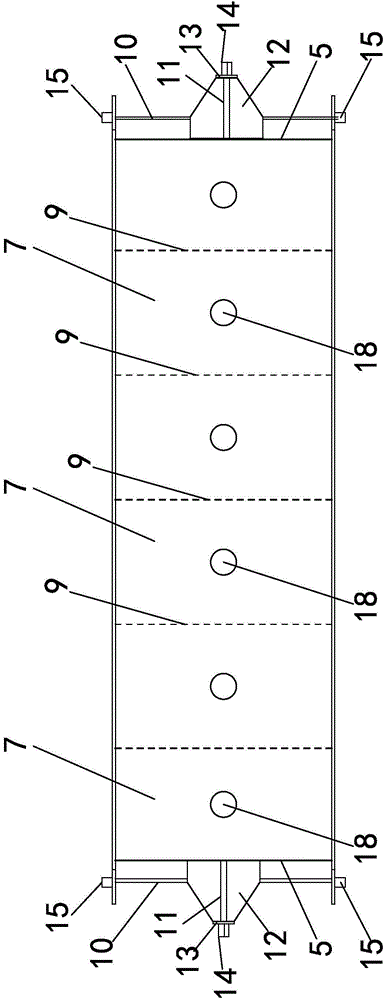

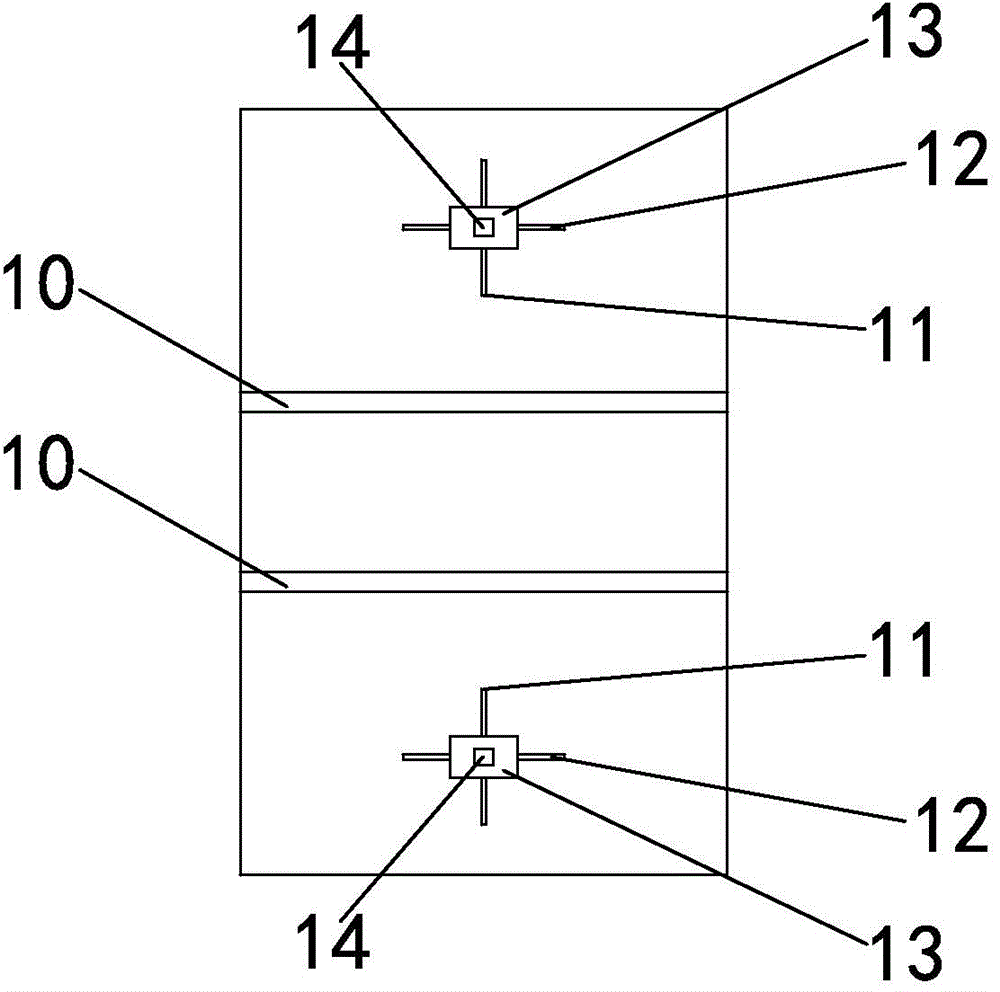

[0056] Such as Figure 1 to Figure 6 As shown, the test tank frame for underwater inspection of the diversion tunnel door slot of the hydropower station includes side column 1, main beam 2 and longitudinal beam 3, and side column 1, main beam 2 and longitudinal beam 3 are all steel structures. There are two side columns 1 on both sides, and the side columns 1 are vertically arranged and placed on the ground. Side column 1 includes side column web 5 and side column flange 4, each side column 1 includes two side column flanges 4, side column flange 4 is arranged on the outside of side column 1, side column flange 4 There are side column webs 5 connected between them. There are several main beams 2, and the main beams 2 are horizontally arranged and respectively connected to the side columns 1 on both sides, so the main beams 2 are vertically connected to the side columns 1. The main beam 2 includes a main beam web 7 and a main beam flange 6, each main beam 2 includes two main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com