Multifunctional, anti-fogging and anti-dazzling composite structure glass

A composite structure and anti-fogging technology, which is applied in parallel glass structures, building components, building structures, etc., can solve the problems of easy fogging of the front windshield, increased engine burden, and blocked glass sight, so as to resist harmful Effects of ultraviolet rays, increased burden, and improved driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

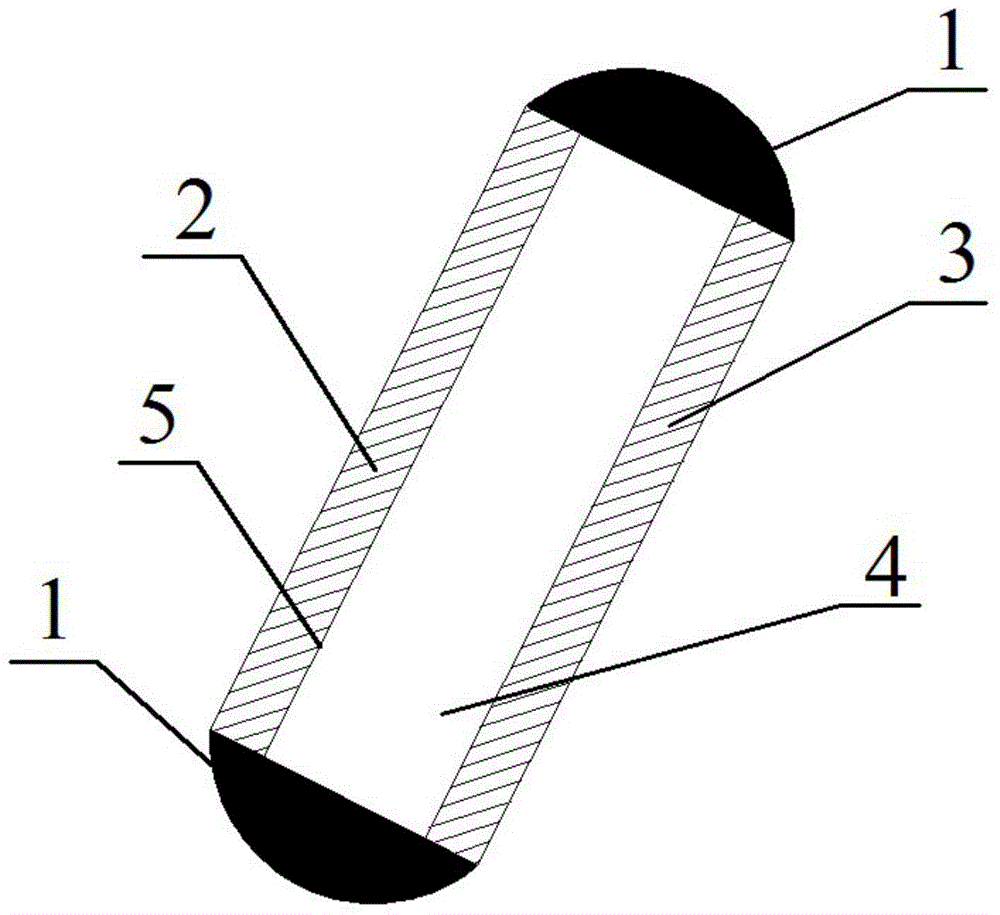

[0022] Such as figure 1 As shown, a multifunctional anti-fogging and anti-glare composite structural glass includes a hydrophobic glass layer 2, a low-emissivity film 5, an inert gas layer 4 and a polarizing glass layer 3 arranged in sequence to form a composite body. The sealing strip 1 realizes the closure. Hydrophobic glass can prevent blurred glass and blocked vision caused by rain; polarized glass focuses on preventing glare caused by strong light; the low-emissivity film and inert gas added between the two layers of glass greatly reduce glass Heat transfer to achieve the purpose of preventing fogging. The multifunctional composite glass provided by this embodiment can block most of the solar radiation heat, and the sunlight can still pass through the glass, so that it can be warm in winter and cool in summer, greatly improving the living environment and the environment inside the car.

[0023] The water-repellent glass layer 2 includes a glass substrate, and the surfac...

Embodiment 2

[0029] refer to figure 1 As shown, this embodiment provides a multifunctional anti-fogging and anti-glare composite structural glass, wherein the thickness of the water-repellent agent layer coated on the glass substrate of the water-repellent glass layer 2 is 1000 angstroms, and the water-repellent glass layer 2 The thickness is 4mm, the thickness of the polarizing glass layer 3 is 3mm, the thickness of the inert gas layer 4 is 5mm, and the thickness of the entire composite structural glass is 12mm.

Embodiment 3

[0031] refer to figure 1 As shown, the present embodiment provides a multifunctional anti-fogging and anti-glare composite structure glass, wherein the thickness of the water-repellent agent layer coated on the glass substrate of the water-repellent glass layer 2 is 500 angstroms, and the water-repellent glass layer 2 The thickness is 3 mm, the thickness of the polarizing glass layer 3 is 4 mm, the thickness of the inert gas layer 4 is 4 mm, and the thickness of the entire composite structural glass is 11 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com