Mining grouting anchor rope

A grouting anchor cable and mine-used technology, which is applied in mining equipment, bolt installation, earthwork drilling and mining, etc., can solve the problem of tensile strength of grouting pipe, low shear strength, threat to the safety of operators, and inability to apply preload Solve problems such as force, achieve convenient and reliable construction technology, improve grouting effect, and improve support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

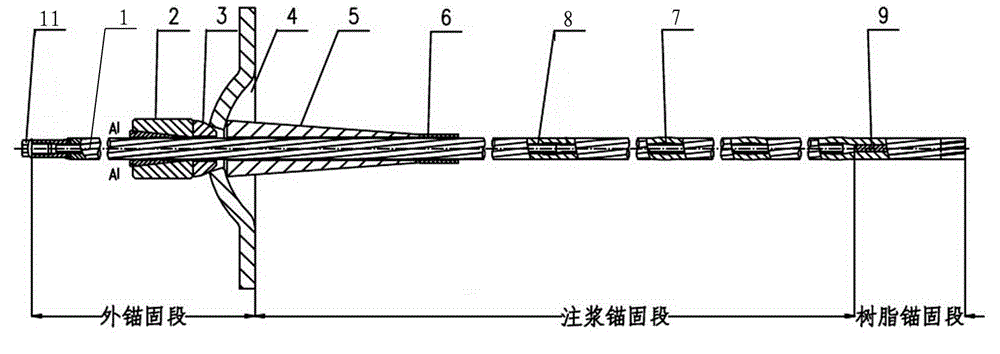

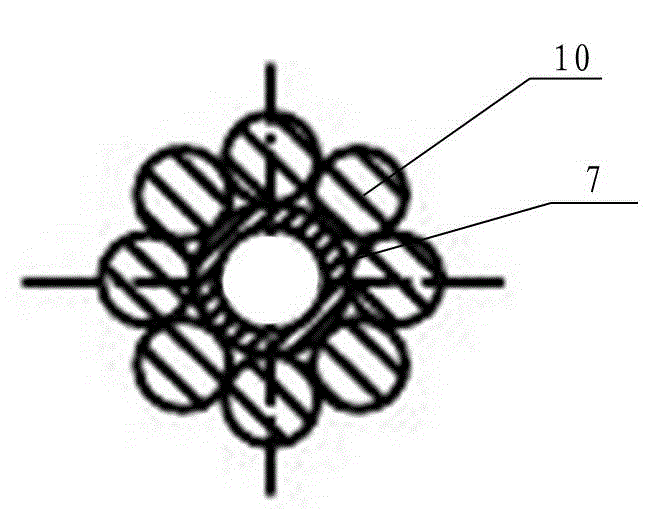

[0021] A mine grouting anchor cable, such as figure 1 , 2 As shown, a round steel 9 is included, and the outer periphery of the round steel 9 is fixed to one end of eight steel strands 10, and the eight steel strands 10 are twisted to form a hollow anchor cable 1.

[0022] The hollow anchor cable 1 is provided with a grouting pipe 7, and one end of the grouting pipe 7 extending into the round steel 9 at the rear end of the hollow anchor cable 1 is closed, and the other end passes through the hollow anchor cable 1 and is set as Internal thread structure, the other end of the grouting pipe 7 is threadedly connected with a quick-plug female head, and the middle and rear part of the grouting pipe 7 is distributed with screen holes; the outer end of the grouting anchor cable is designed as a 19mm inner diameter The quick-plug female head can proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Pulling force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com