Fracture flow simulation experiment device and method for fiber blend support agent

A flow simulation and experimental device technology, applied in the field of petroleum fracturing, can solve problems such as poor reliability, hindering technology development, fiber and proppant migration law and distribution shape cannot be displayed intuitively, and achieve novel structure, safe operation, The degree of automation and the effect of high reliability of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Because the basic theory and laboratory experimental research of fiber fracturing technology lag behind the engineering practice, this technology lacks necessary, scientific and systematic theoretical guidance, which has become a bottleneck restricting the further development and application of this technology. In terms of experimental research on fiber fracturing technology, there are many studies on the static properties of fibers such as dispersibility, compatibility, sand suspension, and degradation at home and abroad, which can more directly and comprehensively reflect the distribution of fibers in fractures, temporary plugging, In terms of dynamic flow simulation of stable sand body characteristics, conventional pre-set fiber sand filling models or core splitting fracture filling fiber methods are often used for evaluation. The distribution pattern in the fiber fracturing field is far from the actual one. The lack of indoor experimental simulation means makes the ...

Embodiment 2

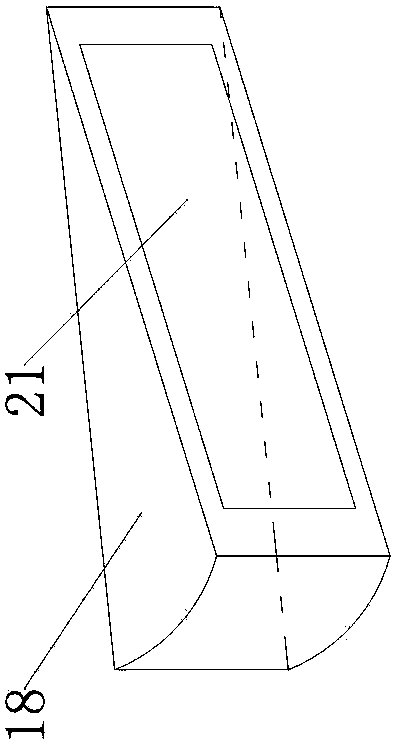

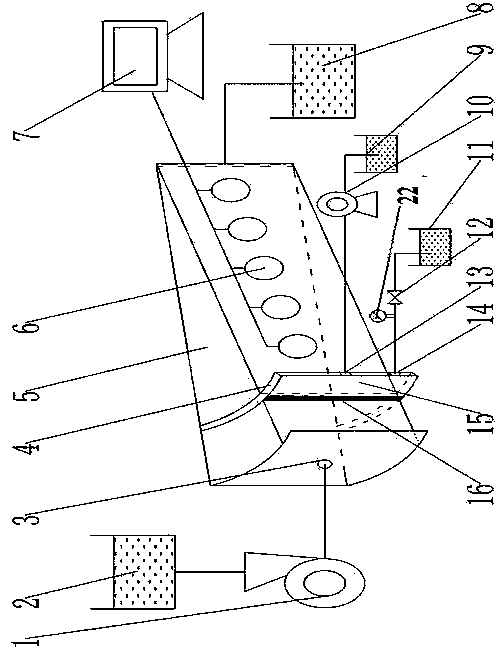

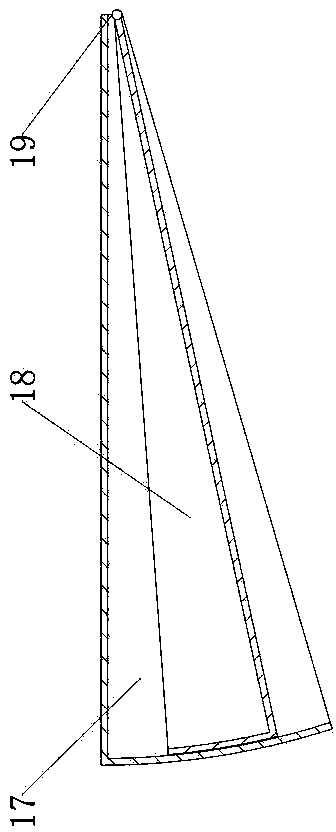

[0041] On the basis of Embodiment 1, a camera 6 is also included, and the camera 6 is arranged outside the glass mother window 20 and the glass sub-window 21 , and a computer 7 is externally connected to the camera 6 .

[0042] The camera 6 is a high-speed camera, and the present embodiment selects a high-speed camera with a pixel of 300w to take pictures and record.

[0043] The glass mother window 20 and the glass sub-window 21 are externally equipped with a camera 6 connected to a computer 7 for recording crack opening, extension and internal material flow state.

[0044] Connected to an external computer 7, the data can be processed directly, and the simulated state can be reached efficiently and quickly.

Embodiment 3

[0046] Based on the fact that in Examples 1 and 2, the experimental process of using the pre-set fiber sand filling model or the core split fracture filling fiber method to simulate temporary fiber plugging, stable sand body, breakthrough pressure, etc. is quite different from the actual, and the reliability of the obtained results is poor. Problem, the present invention accurately simulates the breakthrough pressure of fiber fracturing and studies fiber length and diameter parameters, injection process parameters, degradation and No effect on stress regulation.

[0047] Based on the designed fiber-mixed proppant fracture flow simulation experiment device, a fiber-mixed proppant fracture flow simulation evaluation method integrating fluid preparation, pressure test, pump injection, pressure measurement, and camera recording was established.

[0048] At the same time, the present invention also discloses a fiber-mixed proppant fracture flow simulation evaluation method with sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com