Ellipse interpolation method for welding tube plate based on centrifugal angle change

A technology of tube sheet welding and centrifugal angle, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of unstable interpolation speed, low interpolation accuracy, complex data processing, etc. The effect of burden, speeding up, and reducing the amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

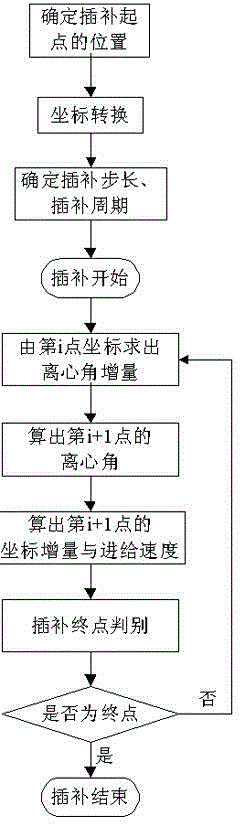

[0039] The present invention provides an ellipse interpolation method for tube-sheet welding based on centrifugal angle variation, such as figure 1 Shown, the present invention comprises the following steps:

[0040] ST1: Determine the position of the starting point of interpolation;

[0041] ST2: Obtain the interpolation period and interpolation line speed according to the required welding trajectory;

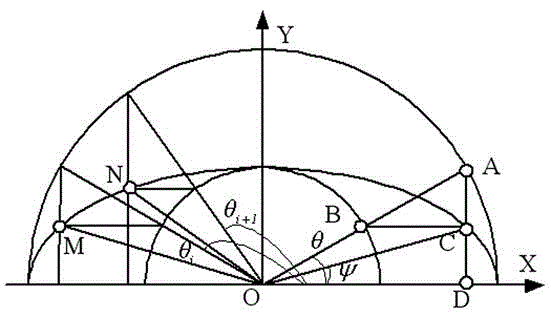

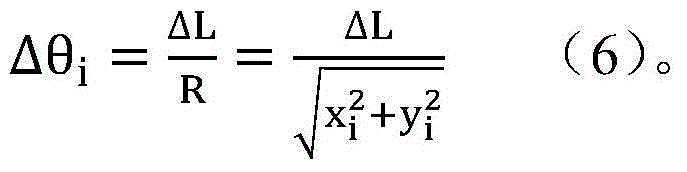

[0042] ST3: Combined with the ellipse parameter equation, calculate the amount of change in the centrifugal angle of the ellipse during each interpolation process;

[0043] ST4: Convert the variation of the centrifugal angle in ST3 to the variation of the coordinate value of the interpolation point in the elliptic curve, and obtain the coordinate of the next interpolation point and the feed speed of each coordinate axis according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com