Rotating electric machine provided with a terminal box

A technology for rotating electrical machines and junction boxes, applied in electrical components, electromechanical devices, structural connections, etc., can solve the problems of fatigue damage and large preload of sheet metal working elements, reduce the risk of fatigue damage, easy to assemble, easy to use the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

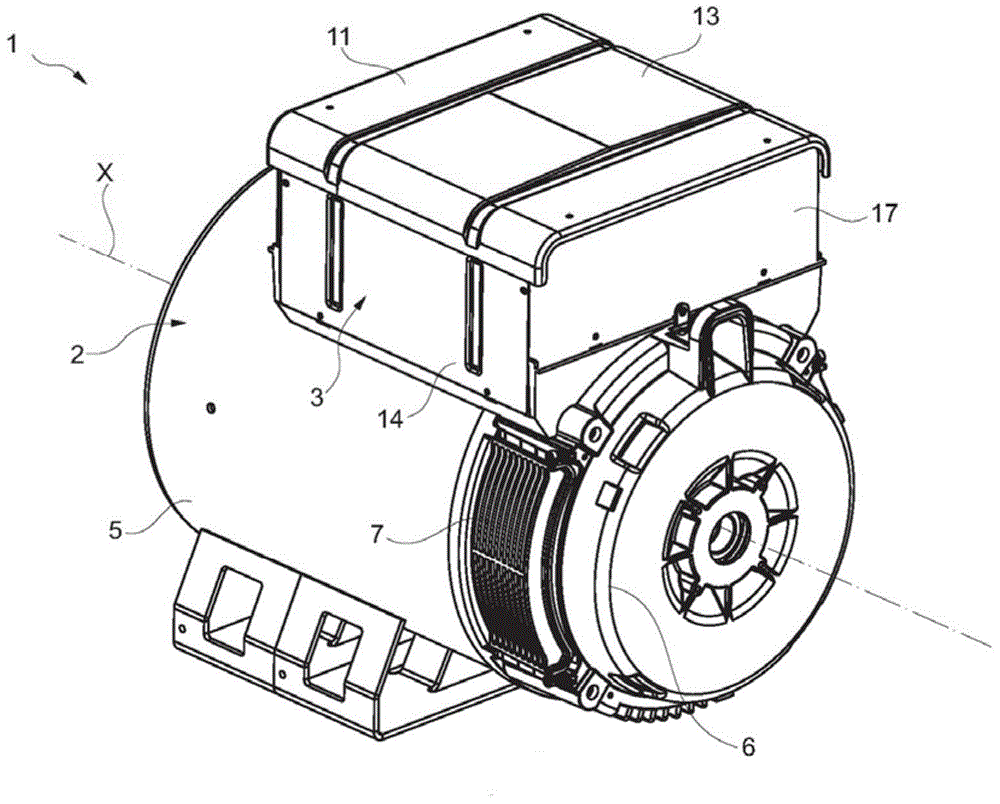

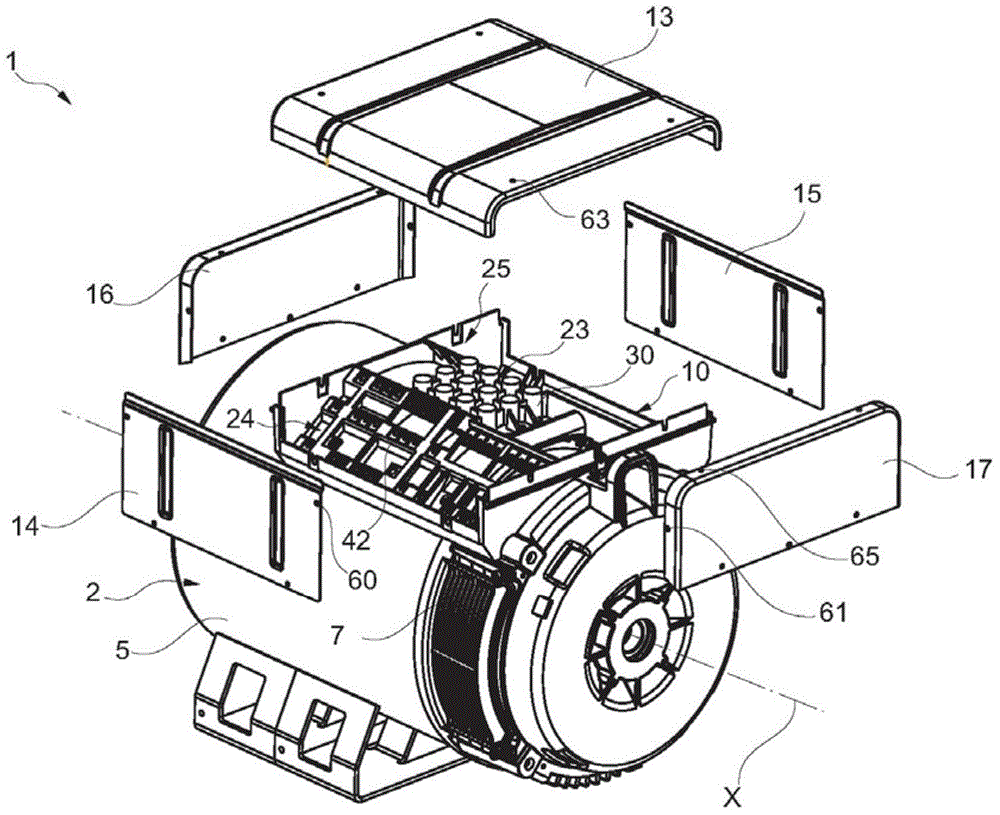

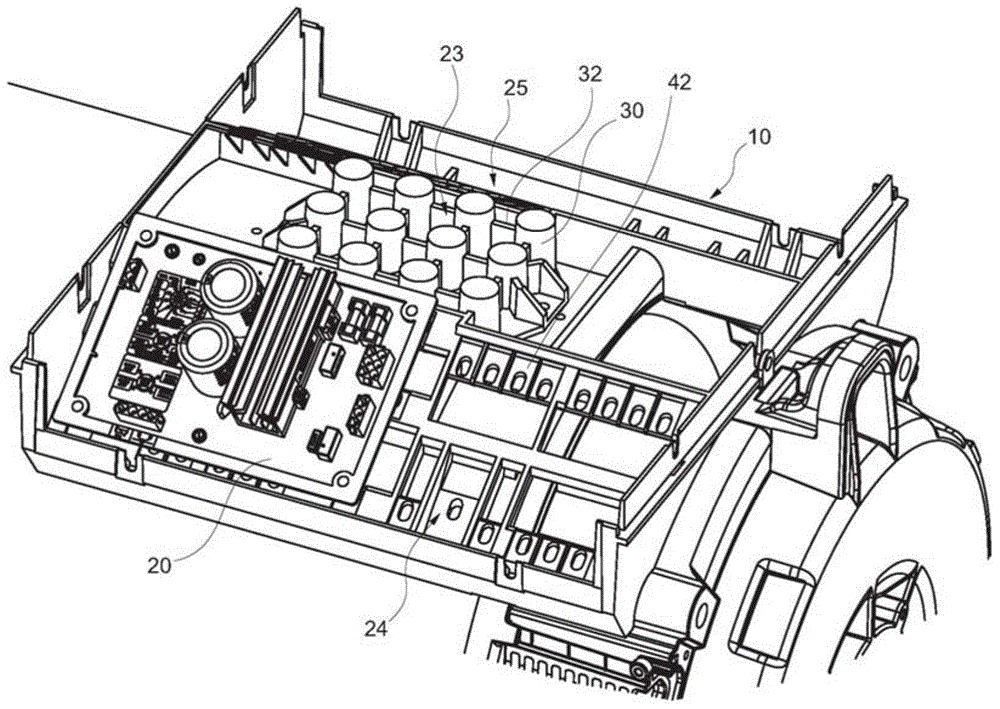

[0055] figure 1 with figure 2 The electrical machine 1 depicted in includes a housing 2 on which a terminal box 3 is mounted, for example as shown, in the upper part of the rotating electrical machine, but this arrangement is only one of various possible examples.

[0056] The housing 2 accommodates, in a manner known per se, a stator of the electric machine and a rotor rotating inside the stator about an axis of rotation X, which in this case coincides with the longitudinal axis of the rotary electric machine 1 .

[0057] As shown, the housing 2 may include a body 5 to which is mounted an end cap 6 which, as shown here, may include a vent 7 .

[0058] In the example shown, the terminal box 3 covers a part of the end cap 6 and the body 5 of the housing 2 .

[0059] The rotating electrical machine 1 is, for example, an alternator, but the invention is not limited to the alternator, and the invention can also be applied to other rotating electrical machines such as motors. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com