Electric welding machine capable of being automatically started and stopped

An electric welding machine and automatic technology, applied in arc welding equipment, welding equipment, welding equipment and other directions, can solve the problems of easy burnout of transformers, reduce the failure rate of welding machines, etc., and achieve the effect of reducing power consumption and air transportation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

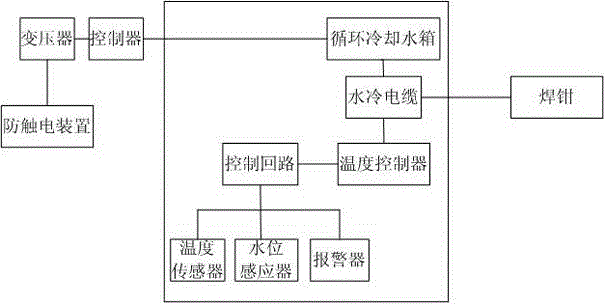

[0020] like figure 1 As shown, this embodiment includes a transformer, a controller, a circulating cooling water tank, a water-cooling cable and welding tongs. The transformer is connected to the circulating cooling water tank and the controller respectively. The water-cooling cable passes through the circulating cooling water tank. connected, and also includes a water flow preventer arranged in the circulating cooling water tank, the water flow preventer is connected with the controller, and the top of the transformer is provided with a cooling fan. The equipment is powered on, and the water inlet switch on the circulating cooling water tank is turned on. When the cooling circulating water passes through the water flow detector, the controller is turned on to let the equipment enter the working state; when the cooling water switch is turned off, no cooling water flows through the water flow. If the circulating cooling water tank suddenly cuts off water during work, the water...

Embodiment 2

[0024] like figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the water flow flood control device includes a temperature sensor, a water level sensor, an alarm and a control loop, and the control loop is connected to the temperature sensor, the water level sensor, and the alarm respectively. The control loop is connected with the controller. The control loop is the command center of the water flow preventer. When the water level sensor detects that the water level in the circulating cooling water tank is low, it will transmit a signal to the control loop, and the control loop will control the alarm to sound a buzzer; if the water level in the circulating cooling water tank When the temperature rises sharply due to lack of water, the temperature sensor will transmit the signal to the controller through the control loop, and the controller will directly cut off the power supply to prevent the water-cooled cable from being burned out due to excessive temperatu...

Embodiment 3

[0026] like figure 1As shown, on the basis of Embodiment 1, this embodiment also includes an electric shock prevention device arranged on the input end of the transformer. When a welding machine that can automatically start and stop is empty, the voltage of the DC welding machine is 55-90V, and the voltage of the AC welding machine is 60-80V, both of which exceed the safe voltage value, but because the voltage is not very high, it is often ignored. In particular, welders have a relatively high risk of electric contact. According to the calculation, when the no-load voltage of the welding machine is 70V, the human body is operating in a humid place, and the protective equipment is not properly worn. At this time, the human body resistance RR is about 1600Ω. If the welder's hand touches the jaws, the current IR = V / RR=70 / 1600=0.044A=44MA, under the action of this current, the welder’s hand will convulse, causing ventricular fibrillation. If the rescue is not timely, there will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com