Device for printing on containers

A technology of printing equipment and printing containers, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of nozzle damage, endangering the health of staff, and clogging of printing heads, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

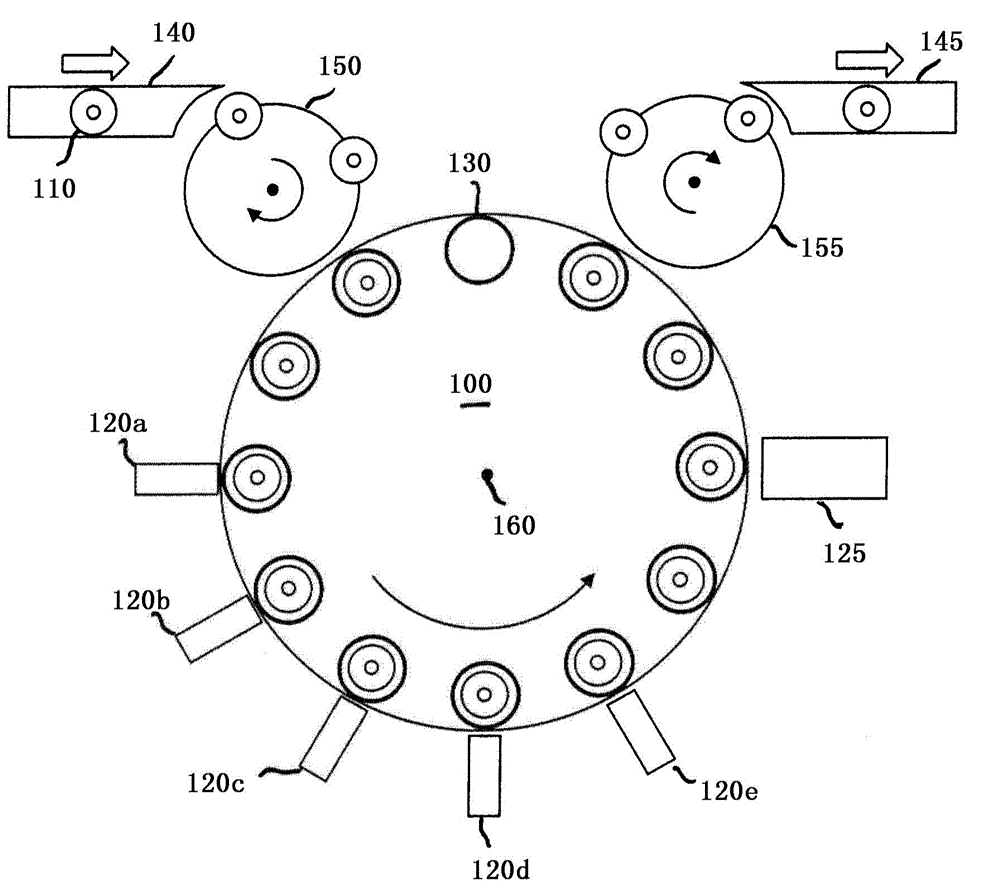

[0073] exist figure 1 A top view of a container handling plant for printing containers 110 can be seen in FIG. The exemplary embodiment shown here with a turntable 100 as a transport system is frequently found in container handling plants in the beverage industry, but also in the field of cosmetics and hygiene products. A monorail of container flow 140 is provided with predetermined segments by a distribution screw conveyor (not shown) and then conveyed to an input star 150 , which holds containers 110 individually and transfers them to the container receptacle of turntable 100 . Before being handed over to the input star 150 , the containers pass through a corona tunnel in which the containers can be electrostatically charged in order to obtain an improved or sharper printed image.

[0074] In this exemplary illustration, the container is shown with a circular cross-section for simplicity, for example as a bottle or bottle-shaped container. However, it is understood that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com