Novel multifunctional hot melt binding machine

A multi-functional, binding machine technology, applied in the direction of book binding, bookbinding, compound continuous process of book processing, etc., can solve the problems of unreasonable structural design, inability to meet the needs of use, complex binding, etc., to achieve diversified functions and appearance. Beautiful, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

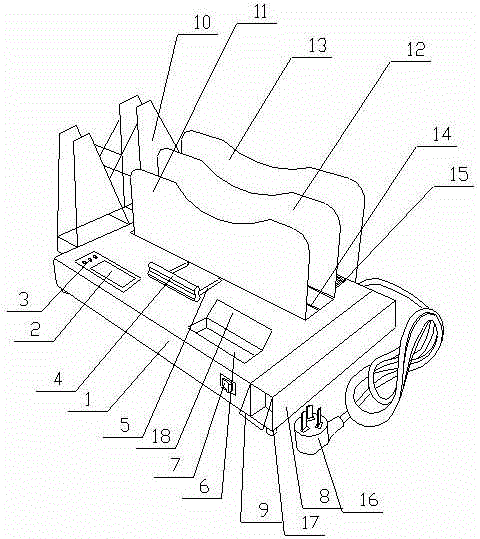

[0018] like figure 1 As shown, this embodiment adopts the following technical solutions: it includes a body 1, a liquid crystal display 2, an operation indicator light 3, a clamping device 4, a clamping chute 5, a storage box 6, a power switch 7, and a binding strip placed Box 8, rubber strip placement box cover 9, telescopic bookshelf 10, first baffle 11, second baffle 12, third baffle 13, heating tank 14, cooling tank 15, power plug 16, support feet 17; The upper surface of the body 1 is provided with a liquid crystal display 2, and one side of the liquid crystal display 2 is provided with several operation indicator lights 3, and the other side of the liquid crystal display 2 is provided with a storage box 6, between the liquid crystal display 2 and the storage box 6 A clamping device 4 and a clamping chute 5 are provided between them, a power switch 7 is provided on one side of the front end of the body 1, a binding tape placement box 8 is provided on one side of the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com