Method for improving concentration of methanol oxo-synthesized dimethyl carbonate crude product

A technology for dimethyl carbonate and oxo synthesis, applied in the purification/separation of carbonate/haloformate, preparation of carbonate/haloformate, chemical instruments and methods, etc., can solve the problem of deactivation, catalyst Problems such as poor recycling and increased production costs can achieve the effect of reducing production costs and reducing the difficulty of separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

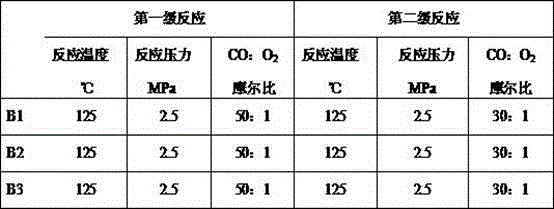

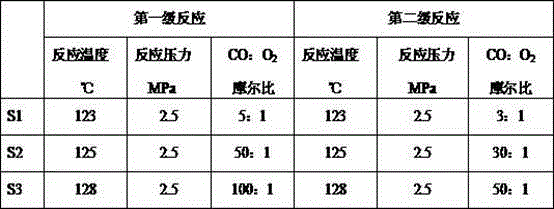

Examples

Embodiment Construction

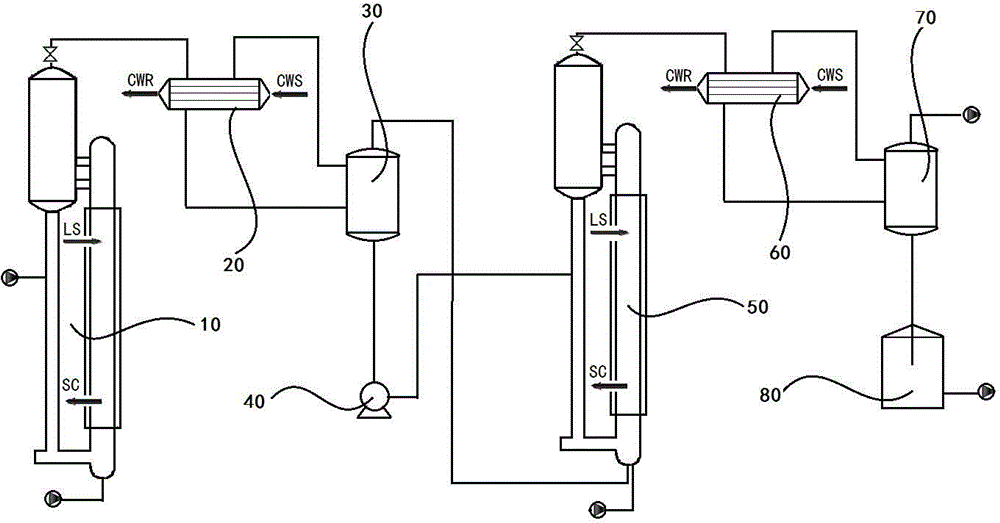

[0015] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] The method for increasing the concentration of the crude product of methanol carbonyl synthesis of dimethyl carbonate is characterized in that it includes a first-order synthesis reaction and a second-order synthesis reaction.

[0017] Among them, the gas-liquid mixture material from the outlet of the first-stage dimethyl carbonate reactor of the first-stage synthesis reaction is condensed and separated; the separated liquid phase is pumped into the middle section of the second-stage dimethyl carbonate reactor to add Participate in the second level of synthesis reaction.

[0018] Wherein, the separated gas including CO enters the bottom of the second-stage dimethyl carbonate reactor and joins in the second-stage synthesis reaction.

[0019] Wherein, during the first-stage synthesis reaction, the dimethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com