Free radical polymerized resin composite and civil construction material

A resin composition and free radical technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced dryness of the coating film surface, low reactivity of free radical polymerizable resins, etc., and achieve excellent tensile properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

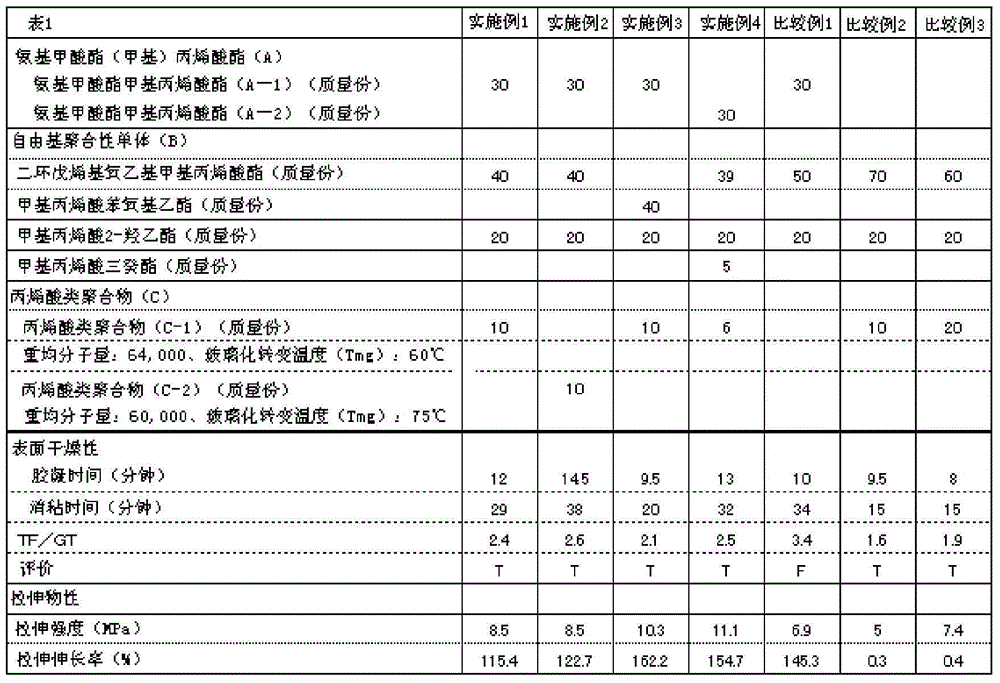

[0068] Hereinafter, the present invention will be described in more detail using examples.

Synthetic example 1

[0069] [Synthesis Example 1] Synthesis of Urethane Methacrylate (A-1)

[0070] Into a four-neck flask equipped with a thermometer, a stirrer, an inert gas inlet, an air inlet, and a reflux cooler, polyester polyol ("Polylight OD-X-2044 manufactured by DIC Corporation", number average molecular weight: 2,000) was charged. 1,000 parts by mass and 174 parts by mass of toluene diisocyanate were reacted at 80° C. for 4 hours under a nitrogen stream. After confirming that the isocyanate group equivalent was 1,100 and almost reached the theoretical value, it was cooled to 50°C. Next, 0.07 parts by mass of hydroquinone and 131 parts by mass of 2-hydroxyethyl methacrylate were added under air flow, and reacted at 90° C. for 5 hours. When the isocyanate % became 0.1% or less, 0.07 mass parts of t-butyl catechols were added, and number average molecular weight: The urethane methacrylate (A-1) of 2,608 was obtained.

Synthetic example 2

[0071] [Synthesis Example 2] Synthesis of Urethane Methacrylate (A2)

[0072] Into a four-necked flask equipped with a thermometer, a stirrer, an inert gas inlet, an air inlet, and a reflux cooler, polycarbonate polyol ("ETERNACOLL UH-200" manufactured by Ube Industries, Ltd., number average molecular weight 2,000) was charged. 1,000 parts by mass and 174 parts by mass of toluene diisocyanate were reacted at 80° C. for 4 hours under a nitrogen stream. After confirming that the isocyanate group equivalent was 1,100 and almost reached the theoretical value, it was cooled to 50°C. Next, 0.07 parts by mass of hydroquinone and 131 parts by mass of 2-hydroxyethyl methacrylate were added under airflow, and reacted at 90° C. for 5 hours. When the isocyanate % became 0.1% or less, 0.07 mass parts of t-butyl catechols were added, and number average molecular weight: The urethane methacrylate (A-2) of 2,608 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com