Photochromic nylon fiber and preparation method thereof

A photochromic, nylon fiber technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component polyamide rayon, etc., can solve the problems of loss of color-changing function, short life of color-changing materials, etc., to achieve simple processing, large-scale Application prospects, the effect of facilitating industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] formula:

[0027] Nylon 6 100 parts

[0028] Photochromic material 3 parts

[0029] Spinning aid 1 part

[0030] The chemical formula of the photochromic material is:

[0031] (C 6 h 6 NO 2 ) · (C 5 h 6 N) 2 ·[PMo 12 o 4 0] (C 6 h 5 NO 2 )·2H 2 O.

[0032] Described spinning aid is magnesium stearate;

[0033] The preparation method of the present invention comprises the steps of:

[0034] After all the components are mixed, they are heated and melted, and then spun by an electrospinning method known in the art to obtain the photochromic nylon fiber.

Embodiment 2

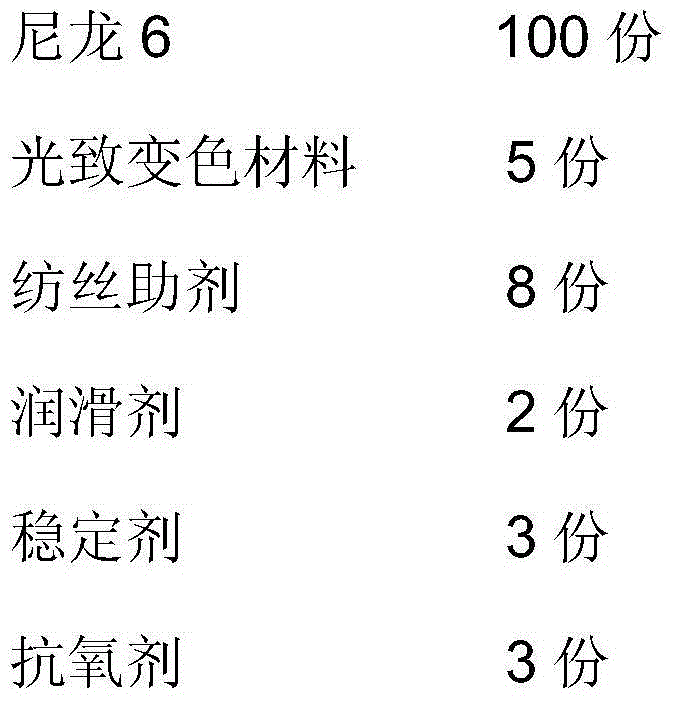

[0036]

[0037] Described photochromic material is the same as embodiment 1, is isonicotinic acid phosphomolybdic acid, and its chemical formula is:

[0038] (C 6 h 6 NO 2 ) · (C 5 h 6 N) 2 ·[PMo 12 o 4 0] (C 6 h 5 NO 2 )·2H 2 O.

[0039] Described lubricant is magnesium stearate;

[0040] Described stabilizer is tartaric acid;

[0041] The antioxidant is vitamin C;

[0042] The preparation method comprises the steps of:

[0043] After all the components are mixed, they are heated and melted, and then spun by an electrospinning method known in the art to obtain the photochromic nylon fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com