Energy-saving heat insulation wall

A technology for thermal insulation walls and walls, applied in thermal insulation, walls, building components, etc., can solve the problems of many wet plastering operations, hidden dangers of fire safety, infeasibility, etc., to reduce wet plastering operations, speed up construction progress, The effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

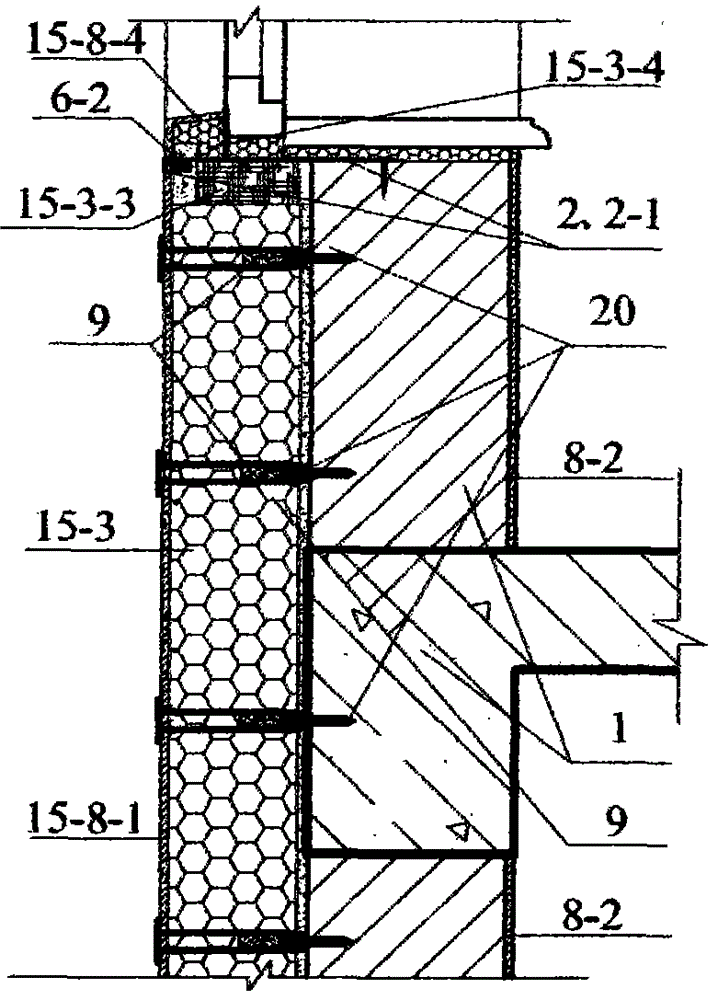

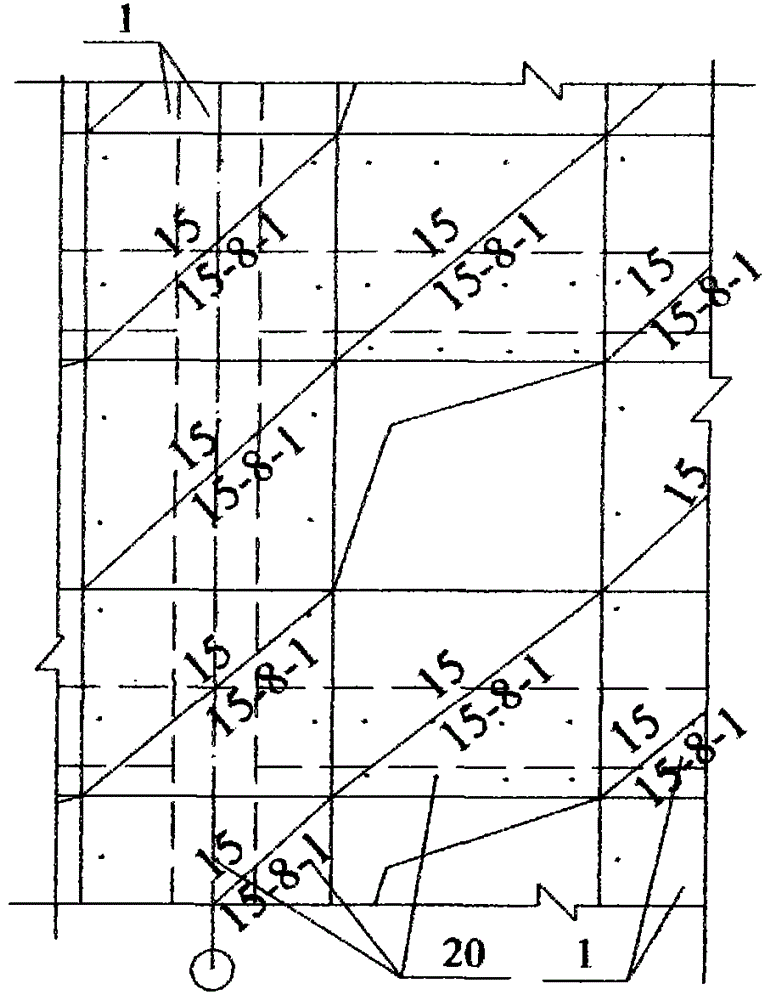

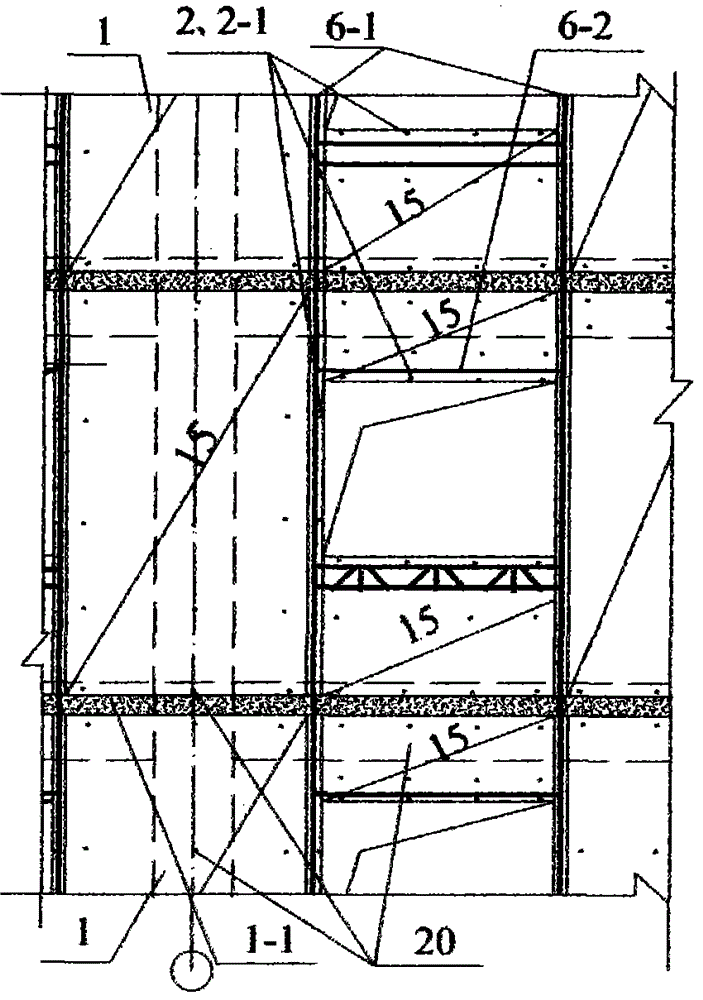

[0129] Implementation mode one: see figure 1 , figure 2 , Figure 25 , an energy-saving and thermal insulation wall of the present embodiment, which is composed of a base wall 1, a prefabricated insulation board 15, and an anchor bolt 20; the base wall 1 is a load-bearing wall or a non-load-bearing wall, and the base wall 1 also includes the main structure of the building in the load-bearing wall or non-load-bearing wall (such as beams and columns of concrete or steel components); the anchor bolt 20 is a steel anchor bolt or a plastic anchor bolt, and the anchor bolt 20 is a nail Type plastic anchor bolts, nail-type steel anchor bolts, or expansion anchor bolts, and anchor bolts for planting bars or pre-embedded anchors, etc.;

[0130] Described prefabricated insulation board 15 is made up of insulation layer 15-3, protection layer 15-8-1, has protection layer 15-8-1 on one side of insulation layer 15-3, insulation layer 15-3 and protection layer 15-1. 8-1 connection (gene...

Embodiment approach 2

[0143] Implementation mode two: see figure 1 The difference between this embodiment and Embodiment 1 is that this embodiment increases the indoor protective layer 8-2, and the indoor protective layer 8-2 is pasted and installed on the indoor side of the base wall 1 to increase the building's earthquake resistance and wind resistance; The protective layer 15-8-1 and the indoor protective layer 8-2 are prefabricated sheet protective layers that meet a certain strength, such as prefabricated sheet protective layers such as fiber reinforced cement fiber boards (including cement fiber boards, calcium silicate boards), or for meeting the requirements of Composite protective layer of prefabricated panels with certain strength and plastering surface.

Embodiment approach 3

[0144] Implementation mode three: see figure 1 , the difference between this embodiment and embodiment one or two is that this embodiment increases the basic material 9; the basic material 9 is injected into the casing of the anchor bolt 20 (such as cement polymer mortar, and the outer end is re-used with thermal insulation material It can be plugged to ensure that the durability is not less than 50 years, which is very convenient and low in price), and the nails or other steel connectors in the protection anchor bolt 20 can meet the durability requirements.

[0145] This measure should only be applied when the installation relies entirely on anchor bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com