Fiber collimator having high-precision ray machine coaxiality, and assembling method thereof

A fiber collimator and optical-mechanical coaxial technology, which is applied in the coupling, installation, and light guide of optical waveguides, can solve the problem that the fiber collimator cannot be matched and adjusted, restricts the manufacturing efficiency of related optical devices, and restricts the optical fiber collimator. Use and other problems, to achieve the effect of simple structure, high optical-mechanical coaxiality, and solve limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

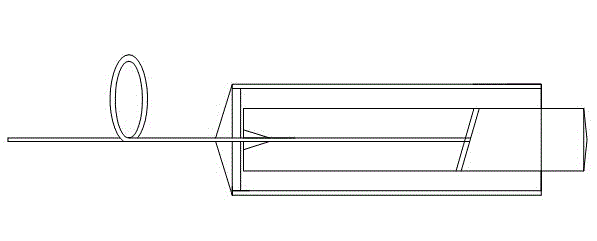

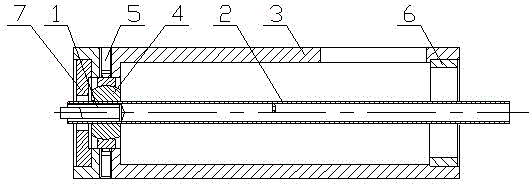

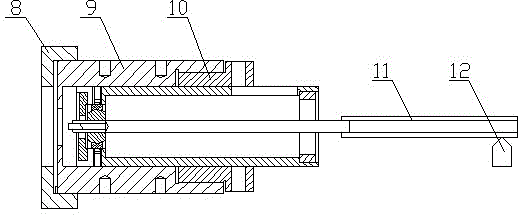

[0033] see figure 1 , the present invention is an optical fiber collimator with high-precision optical-mechanical coaxiality, which includes an optical fiber collimator 1, an inner sleeve 2 and an outer sleeve 3, and the optical fiber collimator 1 is arranged behind the inner sleeve 2 The outer sleeve 3 is set on the outer side of the inner sleeve 2, and the free end fixing part 6 of the collimator, the hinge 4 and the joint end of the collimator are sequentially arranged between the inner sleeve 2 and the outer sleeve 3 from front to back. The fixing part 7, the free end fixing part 6 of the collimator is located at the front end of the outer sleeve 3, the joint end fixing part 7 of the collimator is located at the rear end of the outer sleeve 3, and the hinge 4 is located at the joint end fixing part 7 of the collimator On the front side, the outer casing 3 is provided with screws 5 , and the hinge 4 is fixed by the screws 5 .

[0034] The free end fixing part 6 of the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com