a lighting system

A lighting system and right-angle prism technology, applied in the field of lighting systems, can solve the problems of reducing the illumination of the mask surface and reducing the energy coupling efficiency of the quartz rod 3, so as to improve the uniformity of the pupil, improve the energy coupling efficiency, and reduce the energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

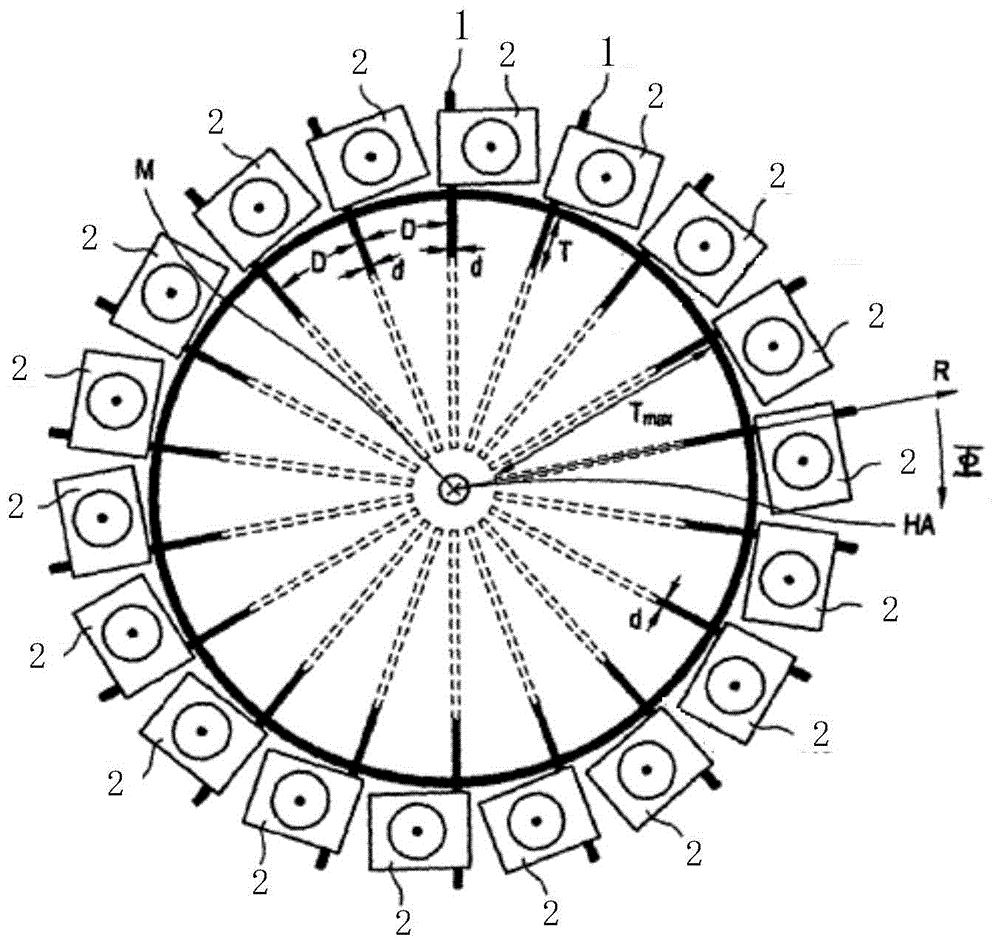

[0051] A lighting system provided by the invention, such as Figure 5 to Figure 9 shown, including sequentially arranged light sources ( Figure 5 not shown in), ellipsoidal bowl assembly 10, coupling lens group 20, deflection module 30, microlens array 40, quartz rod 50, relay lens group 60 and illumination object 70, preferably, the light source is a high voltage Mercury lamp, the ellipsoidal bowl assembly 10 is an ellipsoidal bowl reflector, the light incident end of the folding module 30 is square, the shape of the light outgoing end of the folding module 30 and the light incident end of the quartz rod 50 Similarly, the light emitted by the light source enters the coupling lens group 20 after being converged by the ellipsoidal bowl assembly 10, and then passes through the folding module 30, the microlens array 40 and the quartz rod 50 for multiple reflections to homogenize the light. After that, it enters the relay lens group 60 and is finally imaged on the illumination o...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that the positions of the coupling lens groups are set differently.

[0063] Specifically, the object focal planes of the light source and the coupling lens group 20 are respectively located at the two focal points of the elliptical bowl assembly 10, and the light incident end of the folding module 30 is located at the focal points of the elliptical bowl assembly 10 , the object focal plane of the coupling lens group 20 coincides with the light exit end of the folding module 30, and the microlens array 40 is located at the light exit end of the folding module 30 and the light entrance end of the quartz rod 50 Between, the object-side focal plane of the relay lens group 60 coincides with the light-emitting end of the quartz rod 50 , and the illumination object 70 is located at the image-side focal plane of the relay lens group 60 . This embodiment can achieve the goal of improving the system mask surface illumina...

Embodiment 3

[0065] Please refer to Figure 10 , 11 , as the first modification of the folding module, a surface whose length and width are L*2L in the first prism on the left side and a side whose length and width are L*2L respectively in the third rectangular prism on the right side The surface forms the light-incident end of the folding module, and its length and width are 2L*2L; in the second prism in the upper part, a surface with a length and width of L*2L and a surface of the second right-angle prism in the lower part The surface whose length and width are respectively L*2L constitutes the light output end of the folding module, and its length and width are respectively L*4L.

[0066] Part of the light entering the light-incident end of the refraction module passes through the first prism, the first right-angle prism, and the second right-angle prism in sequence, and then exits the refraction module; the other part of the light-incident end of the refraction module enters The ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com