Radiating film substrate structure and manufacturing method thereof

A manufacturing method and heat-dissipating film technology, which are used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as defective products, influence on adhesion, and poor stability, and achieve improved thermal conductivity and heat dissipation efficiency. Efficiency, good bonding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

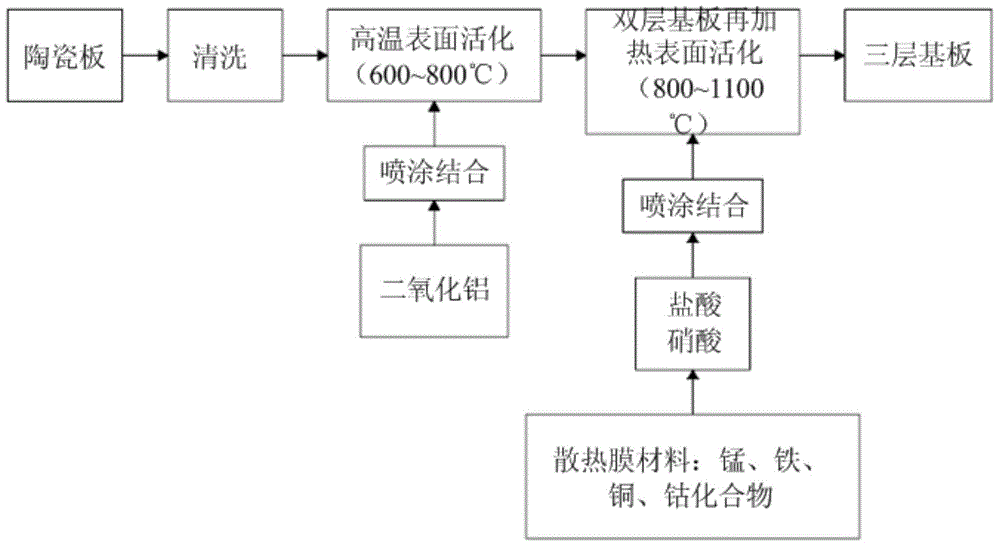

[0023] see image 3 , 4 , The manufacturing method process of the present invention includes: selecting materials, heating for the first time, spraying for the first time, heating for the second time, and spraying for the second time to form a three-layer substrate. The selected materials include: ceramic plate 10 as the substrate, silicon dioxide 11 as the dielectric layer, and manganese, iron, copper, cobalt compounds and other materials as the heat dissipation film 12 .

[0024] Firstly, the ceramic plate 10 is cleaned and dried, preheated at a high temperature of 600-800°C to activate the surface of the ceramic plate 10, and then the alumina 11 is sprayed and bonded to the surface of the ceramic plate 10 to form a double-layer substrate. The double-layer substrate is preheated at a high temperature of 800-1100°C, which also activates the surface of the aluminum dioxide 11, and then sprays the material of the heat dissipation film 12 on the surface of the alumina 11 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com