A kind of heat dissipation coating of waterborne carbon nanotube/epoxy resin dispersion system and its preparation method and application

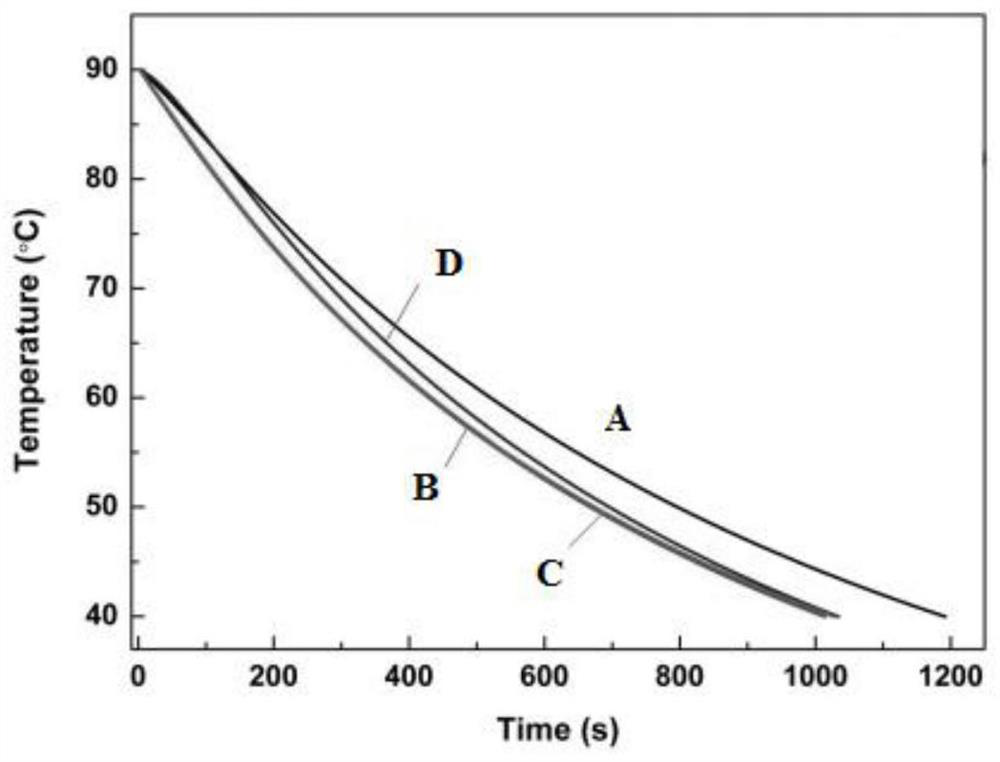

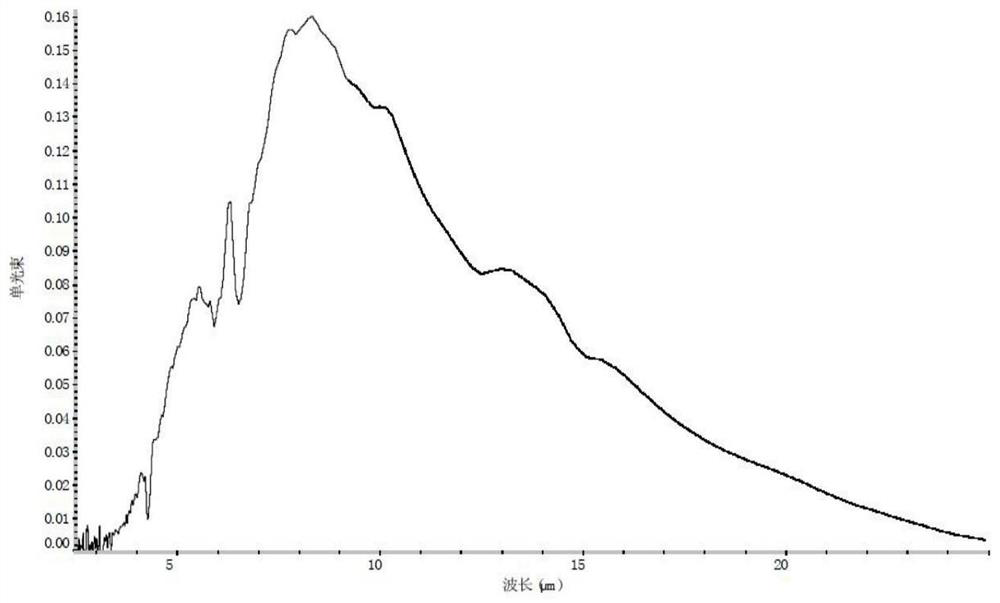

A technology of water-based carbon nanotubes and water-based epoxy resin, applied in epoxy resin coatings, coatings, etc., can solve problems such as poor heat dissipation, improve mechanical properties and heat conduction and heat dissipation efficiency, improve bonding performance, and improve thermal conductivity. and the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a heat dissipation coating of the aqueous carbon nanotube / epoxy resin dispersion system, including the following steps:

[0046] The aqueous epoxy resin, hydrophilic carbon nanotubes, hydrophilic kaolin, water, defoamer, leveling agent, and two-component aqueous epoxy curing agent are mixed to obtain the water-based carbon nanotube / epoxy resin. The heat dissipation coating of the dispersion system.

[0047] In the present invention, the mixing manner is preferably magnetic stirring, the present invention is not particularly limited to the rotational speed and time of the magnetic force, and the raw material can be mixed uniform. In the present invention, the mixing order ensures that hydrophilic carbon nanotubes and hydrophilic kaolin and epoxy resins are sufficiently contacted, and the dispersibility of hydrophilic carbon nanotubes and hydrophilic kaolins in epoxy resins can be improved.

[0048] The present in...

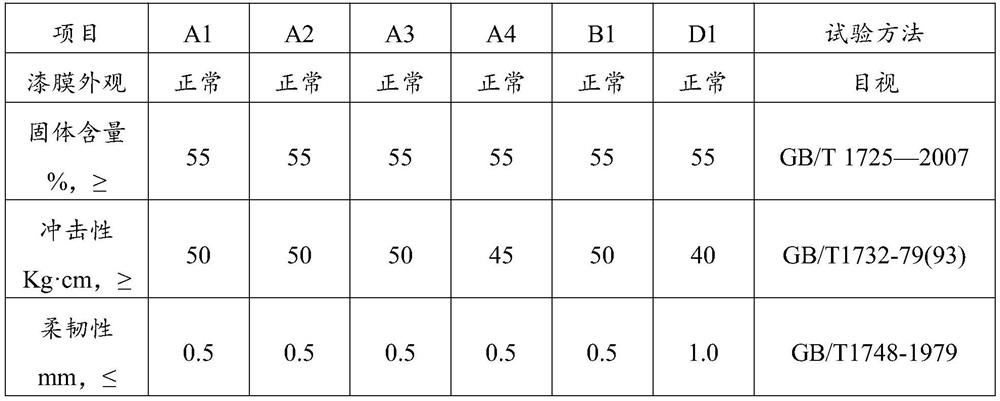

Embodiment 1

[0060] 1G carbon nanotubes were weighed in the beaker, and then 2 g of sodium dodecyl sulfate, 0.5 g of tetrabutylammonium bromide, 3 g of polyvinyl alcohol and 45 ml of distilled water were magnetically stirred to obtain a hydrophilic carbon nanotube;

[0061] 1 g of calcined kaolin in the beaker, then weighted 2 g of sodium dodecyl sulfate, 0.5 g of tetrabutylammonium bromide, 3 g of polyvinyl alcohol, and 45 mL of distilled water, magnetic stirring, resulting in hydrophilic kaolin;

[0062] Weigh 15g aqueous epoxy resin, 8 g of hydrophilic carbon nanotubes, 12 g of hydrophilic kaolin and 3G water in the beaker, stir even, weigh 1 g of tributyl phosphate, 1 g of polyurethane flow flat agent, 3g two group Seed aqueous epoxy curing agent, stirred with a DW-2 increase-level constant speed stirrer for 2 h to dispersion uniform, to obtain a heat dissipation coating of aqueous carbon nanotube / epoxy resin dispersion system.

[0063]The surface of the 12cm × 5 cm galvanized steel shee...

Embodiment 2

[0080] The difference from the first embodiment is different from the amount of the feedstock.

[0081] 1G carbon nanotubes were weighed in the beaker, and then 2 g of sodium dodecyl sulfate, 0.5 g of tetrabutylammonium bromide, 3 g of polyvinyl alcohol and 45 ml of distilled water were magnetically stirred to obtain a hydrophilic carbon nanotube;

[0082] 1 g of calcined kaolin in the beaker, then weighted 2 g of sodium dodecyl sulfate, 0.5 g of tetrabutylammonium bromide, 3 g of polyvinyl alcohol, and 45 mL of distilled water, magnetic stirring, resulting in hydrophilic kaolin;

[0083] Weigh 15g aqueous epoxy resin, 10 g of hydrophilic carbon nanotubes, 12 g of hydrophilic kaolin and 3G water in the beaker, stir even, weigh 1 g of tributyl phosphate, 1 g of polyurethane floral, 3g two group Seed aqueous epoxy curing agent, stirred with a DW-2 increase-level constant speed stirrer for 2 h to dispersion uniform, to obtain a heat dissipation coating of aqueous carbon nanotube / ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com