A self-cleaning optical system

An optical system and self-cleaning technology, which is applied in the field of optical systems, can solve the problems that plastic belts are not suitable for high-temperature processing environments, twisted, and plastic films are easily damaged or twisted by lasers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

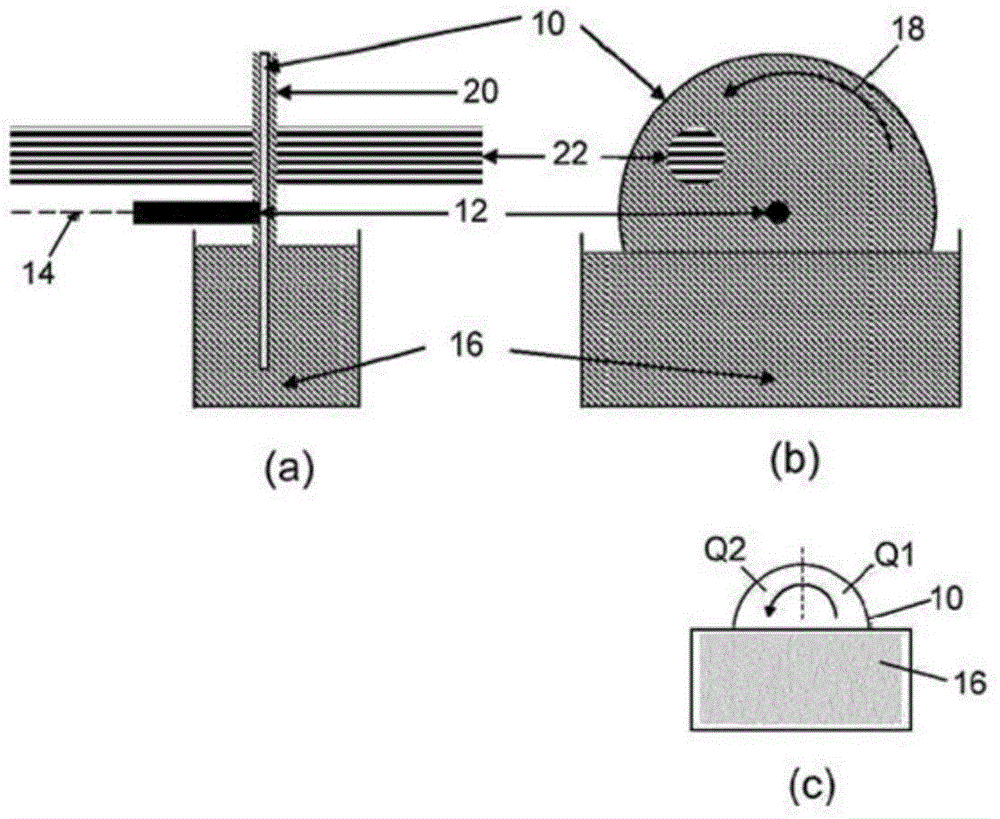

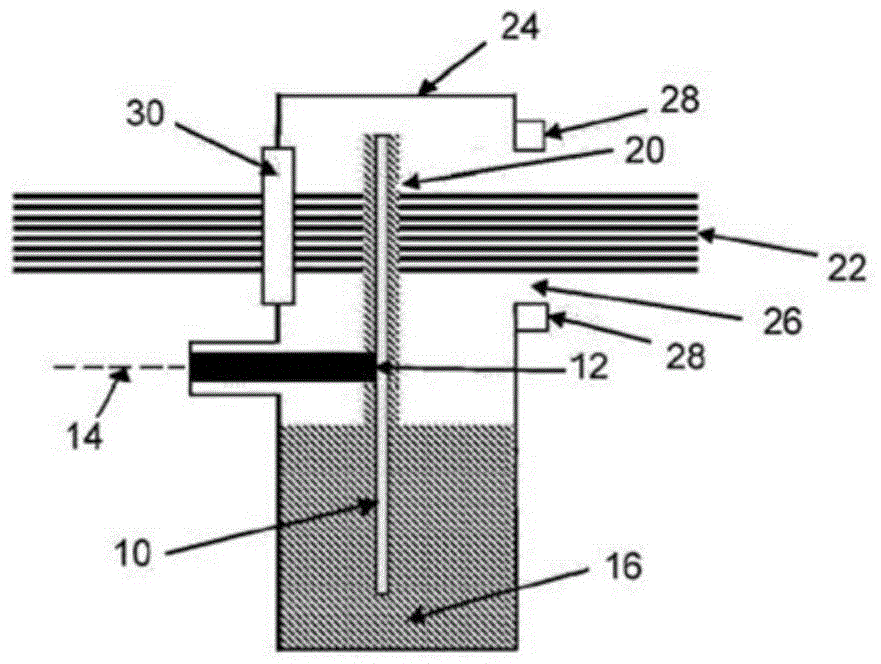

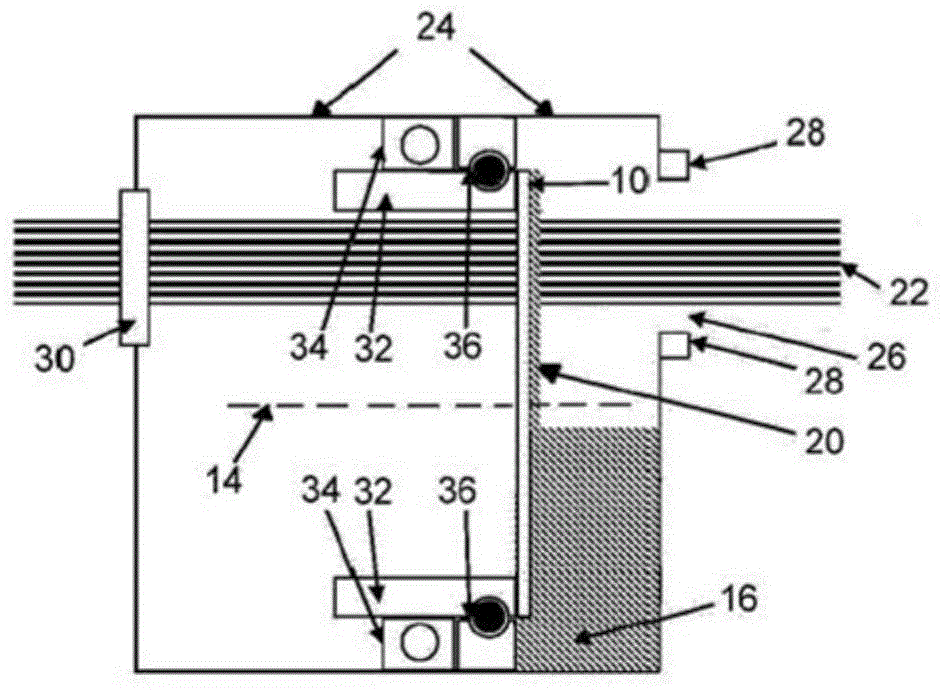

[0034] Please refer to figure 1, the first embodiment of the invention comprises a transparent glass plate 10 in the form of a flat optical disc. Plate 10 is mounted vertically on a shaft 12, rotatable in its own plane about a horizontal axis 14 passing through the center of the disc. Plate 10 may be made of glass, quartz, CaF2, MgF2, LiF or other transparent materials, as the case may be.

[0035] The lower part of the plate 10 is immersed in an oil pool 16 containing transparent oil. During operation, a motor (not shown) keeps the shaft 12 in continuous rotation - as indicated by arrow 18 - so that the lower half of the plate 10 is continuously rotated through the oil. Oils that may be used are fluorocarbon polymer oils, fluoropolymers of polyhexafluorooxypropylene, low vapor pressure polyphenylethyl ether, and other low pressure oils, as the case may be.

[0036] As the plate 10 emerges from the oil sump 16, a thin oil coating 20 remains on the glass. Initially, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com