Method of making outer cigarette wrapper from fresh tobacco leaves and made cigarettes

A technology of outer wrapping and fresh tobacco leaves, which is applied in the field of preparing cigarettes, cigarette outer wrappings, and manufactured cigarettes, and can solve problems such as health hazards and inhalation into the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

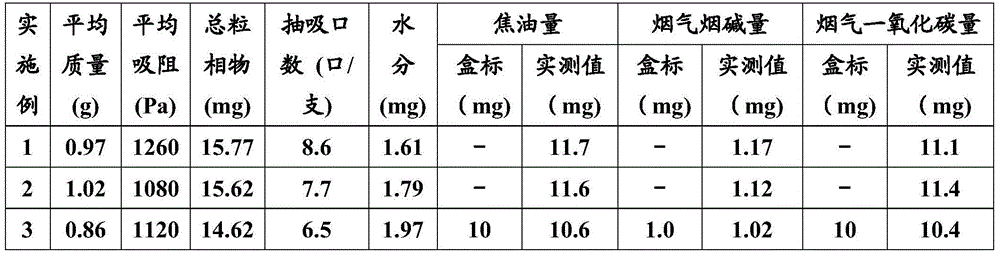

Embodiment 1

[0072] Example 1: Utilize the wrapper prepared by fresh tobacco leaves and hand-made cigarettes

[0073] (1) Gather tobacco leaves from the field. Choose mature middle tobacco leaves in the field, fasten the base of the leaves with your fingers, and fold them down horizontally. Handle them with care and do not squeeze them, so that the tobacco leaves will not appear blue marks due to cracking or damage.

[0074] (2) The tobacco leaves brought back are weaved and hung on the rod. When making tobacco, the petioles are aligned and the backs of the leaves are leaning against each other. The hanging rods are required to be dense and consistent, and the distance between the rods is preferably 20-25cm. Tobacco is tied with ordinary tobacco rods in the air-flow descending intensive barn. The length of the tobacco rods is 145cm, of which the woven tobacco part is 130cm. There are 65 bundles of artificially woven cigarettes per rod, 2 pieces / bundle, and each bundle occupies a positio...

Embodiment 2

[0088] Embodiment 2: Utilize the wrapper and the cigarette (2) prepared by fresh tobacco leaves

[0089] (1) Gather tobacco leaves from the field. Choose mature middle and lower tobacco leaves in the field, fasten the base of the leaves with your fingers, and fold them down horizontally. Handle them gently and do not squeeze them, so that the tobacco leaves will not appear blue marks due to cracking or damage.

[0090] (2) The tobacco leaves brought back are weaved and hung on the rod. When making tobacco, the petioles are aligned and the backs of the leaves are leaning against each other. The hanging rods are required to be dense and consistent, and the distance between the rods is preferably 20-25cm.

[0091] (3) The tobacco leaves on the pole are roasted and dehydrated according to the traditional method. When baking, the tobacco leaves gradually turn yellow, and the tobacco leaves gradually become soft while gradually turning yellow. Continuous baking makes the whole...

Embodiment 3

[0096] Embodiment 3: the making of traditional cigarette

[0097] Traditional cigarette manufacturing process: It consists of three main processes: silk making (raw material processing), coiling (rolling molding), and packaging (packaged finished product).

[0098] Silk-making process: including material preparation, dampening, leaf storage, shredding, drying, mixing leaves and stalks, flavoring, feeding, and silk storage. Its technological task is to make all kinds of tobacco leaves into shredded tobacco with uniform ratio, purity and no impurities, and the width, moisture and temperature meet the technical requirements of various grades of cigarettes. The formula and tightness of the shredded tobacco in Example 3 are the same as those in Example 1.

[0099] Rolling process: including silk feeding, cigarette rolling, filter tipping and other processes. Its technological task is to give full play to the efficiency of the equipment, roll the qualified shredded tobacco into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com